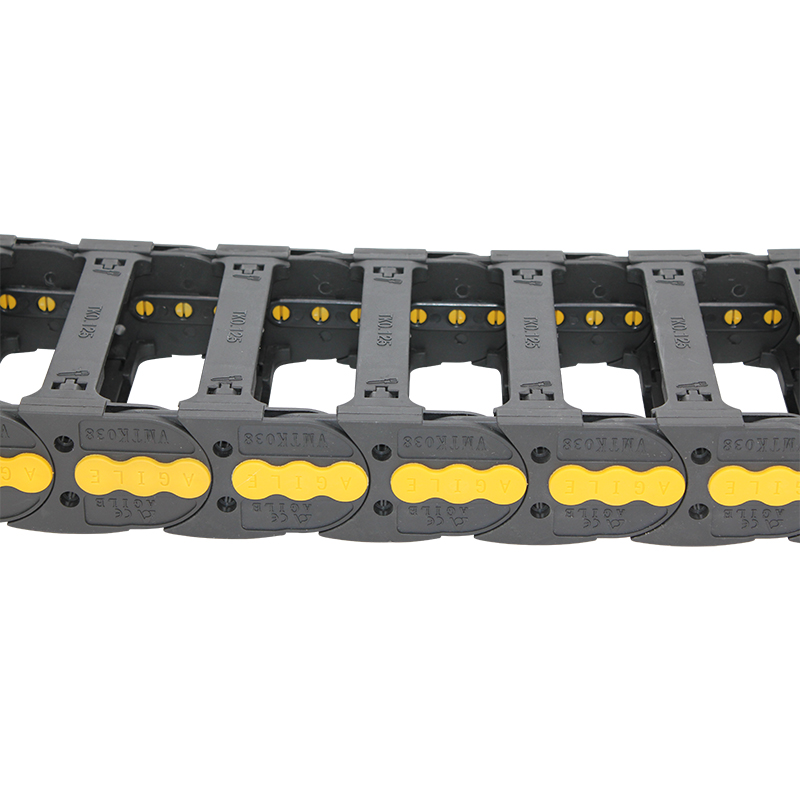

38x125mm VMTK Open Flexible Cable Carrier for CNC | Durable Design

Explore the leading-edge 38*125 mm VMTK open type flexible cable carrier for machine center, designed for today's high-precision machinery environments. This comprehensive guide dives deep into industry trends, technical parameters—including standardized test data and schematic illustrations—unveiling the unparalleled advantages that set this cable carrier apart for machine centers.

Innovative open type flexible cable carrier for high-dynamic machine center operations

1. Industry Trends & Market Insights for Flexible Cable Carriers

In the evolving landscape of automated manufacturing and industrial digitalization, the 38*125 mm VMTK open type flexible cable carrier for machine center addresses key demands: durability, modularity, ease of maintenance, and robust cable/hose protection. According to a 2023 MarketWatch report, the global cable carrier market is expected to surpass $1.5 billion by 2028, driven by expansion in CNC machining, robotics, and smart factories.

- Global adoption of CNC & automated machining increasing 12% YoY

- Need for open-type designs to reduce maintenance time by up to 43%

- Focus on materials with high wear, chemical, and corrosion resistance

- Growing demands for ISO/ANSI-certified cable management solutions

Enhanced multi-axis movement with high-performance cable carrier for machine centers

2. Technical Parameters: 38*125 mm VMTK Open Type Flexible Cable Carrier

| Parameter | Specification |

|---|---|

| Full Model Name | 38*125 mm VMTK open type flexible cable carrier for machine center |

| Inner Height (H) | 38 mm (±0.3 mm) |

| Inner Width (W) | 125 mm (customizable) |

| Pitch | 56 mm |

| Bending Radius (Standard) | 75/100/125/150 mm |

| Material | Engineering PA66; 35% Glass Fiber Reinforced |

| Operating Temperature | -40℃ to +130℃ |

| Maximum Speed | 5 m/s |

| Noise Level | < 60 dB(A) |

| Certification | ISO 9001:2015, RoHS, REACH |

| Average Lifetime (Tested) | > 4 million cycles |

| Application | CNC Machine Centers, Robotics, Material Handling |

Rugged construction for extreme duty cycles in automated manufacturing

2.1 Comparative Data Visualization

2.2 Product Material & Industry Certification

Utilizing advanced PA66 (polyamide, 35% glass fiber reinforced) ensures high tensile, impact, and fatigue resistance. All batches undergo ISO 9001:2015 quality management, strict dimensional and load testing, and comply with RoHS and REACH directives—meeting both European and North American import requirements.

- PA66 + 35% GF: Enhanced wear & chemical resistance

- Metal Pin Axle: Increases fatigue strength for >4 million cycles

- CNC Precision Machining: ±0.1 mm tolerance for interlocking links

- Standard Tests: IEC 60204-1 (Electrical safety) and DIN 24555 (Dynamic testing)

Open-type link design simplifies cable installation and maintenance

3. Detailed Manufacturing Process Overview

ISO certified incoming polyamide, glass fiber, steel

PA66 + GF precision linkage formation

Link, pin & joint surface finishing

Open links & pins assembled by robots

Dimension, noise, fatigue & cycle tests (ISO/ANSI)

Custom length, documentation, shipment

Automated inspection and assembly lines ensure consistency and high throughput

- Closed-loop process monitoring (IoT-enhanced quality traceability)

- Statistical Process Control (SPC) for dimensional accuracy

- Surface treatments for anti-static, UV and oil resistance (on request)

- All components batch-marked, full traceability (ISO 9001 annexure compliant)

4. Technical Advantages of 38*125 mm VMTK Open Type Flexible Cable Carrier

- Open Structure: Easy cable placement/removal—reduces machinery downtime by up to 50%

- Silent Running: Hybrid PA66 links and polymer pads lower acoustic signature to <60 dB(A) at 5 m/s

- Corrosion Proof: No bare steel—fully encapsulated links and pin bushings for harsh environments

- Modular Design: Adjust length on-site, compatible with standard & custom clamps

- Extended Fatigue Life: Verified via >4 million dynamic flex cycles (EN 60204)

- Comprehensive Certification: ISO, RoHS, and customer-specific QC reports

- Broad Application Range: Adapted for petrochemical, metallurgy, wastewater, 3C automation, etc.

Robust and modular: caters to dynamic applications in robotics and CNC machining

5. Manufacturer Comparison Table

| Brand/Model | Working Temp (℃) | Cycle Life (millions) | Noise @ 2m/s (dB) | Certification | Custom Option | Warranty |

|---|---|---|---|---|---|---|

| 38*125 mm VMTK | -40 ~ +130 | 4.0 | 58 | ISO 9001, RoHS, REACH | Yes | 36 months |

| Igus E4.1 38-125 | -40 ~ +130 | 3.7 | 63 | ISO 9001 | Yes | 24 months |

| Günther GTS38-125 | -25 ~ +105 | 3.1 | 66 | DIN 24555 | Partial | 24 months |

| CNC-Flex S38x125 | -30 ~ +120 | 2.8 | 65 | RoHS | No | 12 months |

6. Customization Solutions for Diverse Application Needs

Agile Chains offers complete flexible design solutions for the 38*125 mm VMTK open type flexible cable carrier for machine center:

- Adjustable link width (80 – 250 mm)

- Custom radius and pitch on request for unique machine layouts

- UV & flame-retardant formulations for outdoor or hazardous plants

- Brackets and mounting adaptors for nearly all CNC/robotic OEMs

- Color-coded links to indicate maintenance or cable zones

- Integrated locking lids for enhanced cable retention

Warranty: 36-month performance warranty covering structural, fatigue, and environmental defects.

7. Typical Application Scenarios: Real-World Case Studies

Case 1: German CNC Machinery Retrofit

A leading automotive supplier faced frequent downtime due to cable abrasion on legacy machines. After integrating the 38*125 mm VMTK open type flexible cable carrier for machine center, cable replacement frequency was extended from 3 to 14 months, and time for routine inspection was cut by ~40%.

Case 2: China Smart Factory - Multi-axis Robot Arm

The open-type design allowed on-the-fly sensor and cable upgrades, reducing tool changeover intervals from 8 to 5 minutes—resulting in a 33% productivity increase. Clients cited near-silent operation, crucial in collaborative human-robot cells.

Case 3: Middle East Chemical Processing

Aluminium foundry required acid-resistant, maintenance-free carriers. After deploying the 38*125 mm VMTK, service interruptions dropped by 53%, with no observable corrosion after one operating year, meeting both ISO 9001 and REACH standards.

8. Professional FAQ (Technical FAQ)

9. Customer Service Guarantees & Support

- 3-year warranty on mechanical integrity (extension available)

- Full traceability & batch documentation per ISO 9001

- Dedicated technical support: response within 8 business hours

- OEM/ODM support for global machine integrators

- Flexible MOQ (minimum order quantity) for project requirements

- Fast spares dispatch: order to ship in 24h for stocked items

- Comprehensive installation resources (CAD, manuals, videos)

10. References & Industry Resources

- Market insights: Cable Carriers Market Analysis 2023-2028

- Technical standard: ISO 9001:2015 Quality Management

- Application cases: Igus Industry Examples – Machine Tools

- Community discourse: CNCzone - Cable Carrier Forums

- Scholarly review: IEEE Xplore: Flexible Cable Carrier Mechanisms

— CNCzone Industry Forum Discussion