Reinforced Drag Chain: Heavy-Duty Cable Protection Solutions

The Evolution of Cable Management: Understanding reinforced drag chain

In the dynamic landscape of modern industrial automation, the efficient and reliable management of cables and hoses is paramount. As machinery becomes more complex, faster, and operates in increasingly demanding environments, standard cable management solutions often fall short. This is where the reinforced drag chain emerges as a critical component, offering superior protection, extended service life, and enhanced operational reliability. These specialized energy chains are engineered to withstand higher loads, resist abrasion, and endure extreme conditions, becoming the backbone of high-performance machinery across various sectors.

Industry Trends Driving the Demand for Reinforced Drag Chains

The industrial sector is undergoing a profound transformation driven by several key trends, all of which underscore the growing necessity for robust cable management systems like the reinforced drag chain:

- Industry 4.0 and Automation Expansion: The push towards fully automated factories, robotics, and smart manufacturing demands continuous, high-speed movement of machinery. This increases wear and tear on traditional cable systems, making durable, reinforced solutions indispensable.

- Harsh Operating Environments: From the corrosive atmospheres of chemical plants to the abrasive dust of mining operations, industrial machinery frequently operates in conditions that degrade standard components rapidly. Reinforced drag chain units are designed with advanced materials and construction to resist such challenges.

- Increased Load and Speed Requirements: Modern gantry systems, large machine tools, and material handling equipment carry heavier loads and operate at much higher speeds. This translates to greater mechanical stress on energy chains, necessitating enhanced structural integrity.

- Miniaturization and Space Optimization: While demanding robust performance, there's also a concurrent trend towards more compact machine designs. Reinforced drag chain solutions often offer high load capacity within optimized dimensions, ensuring efficient use of space without compromising durability.

- Sustainability and Longevity: Industries are increasingly focused on reducing downtime and material waste. Investing in a long-lasting, reliable reinforced drag chain contributes to sustainability by extending maintenance cycles and improving overall equipment effectiveness (OEE).

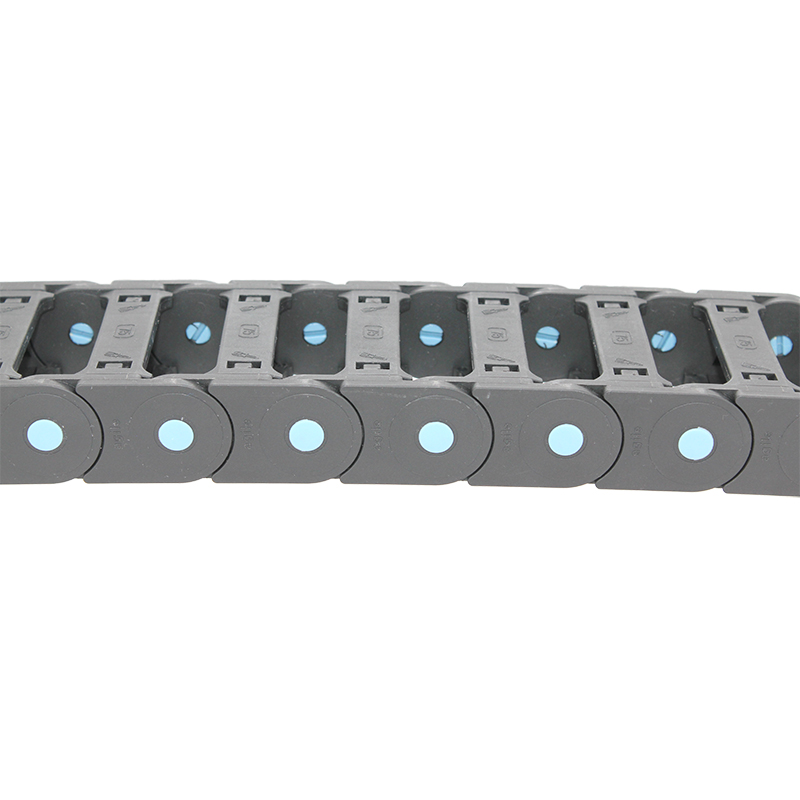

Technical Parameters and Specifications of 2575 mm MTK reinforced bridge type both side openable energy chain

Understanding the technical parameters of a reinforced drag chain is crucial for selecting the right component for a specific application. The product, `2575 mm MTK reinforced bridge type both side openable energy chain` (Product URL: https://www.agilechains.com/2575-mm-mtk-reinforced-bridge-type-both-side-openable-energy-chain.html), exemplifies a high-performance solution. Here's a breakdown of typical parameters:

Key Parameter Definitions:

- Inner Height (Hi): The internal usable height of the chain link, determining the maximum outer diameter of cables/hoses it can accommodate.

- Inner Width (Wi): The internal usable width, dictating the total bundle width of cables/hoses.

- Outer Height (Ha): The overall height of the chain link.

- Outer Width (Wa): The overall width of the chain link.

- Bend Radius (R): The minimum radius the drag chain can bend without stressing the cables/hoses inside. Crucial for dynamic applications.

- Pitch (P): The length of a single chain link. Affects the overall smoothness of movement and noise levels.

- Max. Unsupported Length: The maximum horizontal distance the chain can bridge without sagging, often enhanced in reinforced drag chain designs.

- Max. Travel Speed: The maximum linear speed at which the chain can operate reliably.

- Max. Acceleration: The maximum rate of change of speed the chain can withstand.

- Service Life: Measured in cycles (number of back-and-forth movements) or kilometers, reflecting the durability of the chain. For reinforced drag chain, this is significantly higher due to robust construction.

- Material: Typically high-performance engineering plastics, often reinforced with glass fibers for increased strength, rigidity, and wear resistance. Examples include PA66 with specific glass fiber content.

- Operating Temperature Range: The ambient temperature range within which the chain maintains its mechanical properties.

- Chemical Resistance: Ability to withstand exposure to various chemicals, oils, and coolants.

Table: Typical Reinforced Drag Chain Parameter Comparison

| Parameter | Standard Drag Chain | Reinforced Drag Chain (e.g., 2575 mm MTK) | Unit |

|---|---|---|---|

| Inner Height (Hi) | 15 - 35 | 25 - 80+ | mm |

| Inner Width (Wi) | 20 - 100 | 50 - 300+ | mm |

| Bend Radius (R) | 28 - 150 | 40 - 350+ | mm |

| Max. Unsupported Length | 0.8 - 2.5 | 3.0 - 8.0+ | m |

| Max. Travel Speed | 5 - 8 | 10 - 20+ | m/s |

| Max. Acceleration | 10 - 20 | 30 - 50+ | m/s² |

| Service Life (Cycles) | 1 million - 5 million | 5 million - 20 million+ | cycles |

| Material | PA / PP | High-grade PA66-GF / Engineered Polymer Alloys | - |

| Operating Temp. | -20°C to +80°C | -40°C to +120°C | °C |

| Load Capacity | Medium | High to Very High | - |

Process Flow: Manufacturing the Reinforced Drag Chain

The manufacturing of a reinforced drag chain is a meticulous process, primarily relying on advanced injection molding techniques for engineering plastics. Unlike metal components which might involve casting or forging, plastic drag chains derive their strength and precision from highly controlled molding and assembly. The `2575 mm MTK reinforced bridge type both side openable energy chain` is a prime example of this precision engineering.

Detailed Manufacturing Process:

-

Raw Material Selection:

- Description: The foundation of a high-performance reinforced drag chain lies in the selection of superior raw materials. For the MTK series, this typically involves high-grade Polyamide (PA66) combined with specific glass fiber (GF) reinforcement. This composite material is chosen for its exceptional mechanical strength, wear resistance, fatigue life, and chemical stability.

- Key Property: Glass fiber reinforcement significantly increases the tensile strength, flexural modulus, and impact resistance of the plastic, allowing the chain to withstand higher dynamic loads and abrasive environments. Specific flame retardant additives (e.g., meeting UL94-V0) may also be incorporated for safety in certain applications.

-

Precision Injection Molding:

- Description: Granulated raw material is fed into high-precision injection molding machines. Under controlled temperature and pressure, the plastic is melted and injected into intricately designed molds that form the individual links (e.g., upper and lower shells, side bands, crossbars) of the reinforced drag chain.

- Process Control: Parameters such as melt temperature, injection speed, holding pressure, and cooling time are precisely monitored and adjusted to ensure consistent part quality, dimensional accuracy, and optimal material crystallization, which is critical for the chain's mechanical integrity.

- Reinforcement Integration: The design of the mold and the injection process are optimized to ensure uniform distribution of glass fibers within the plastic matrix, maximizing the reinforcement effect and preventing weak points.

-

Quality Inspection of Molded Components:

- Description: After molding, individual components undergo rigorous quality checks. This includes visual inspection for defects (e.g., short shots, flash, warpage), dimensional verification using precision calipers and optical measuring equipment, and material property testing.

- Standards Adherence: Components are checked against strict internal specifications and international standards like ISO 9001 for quality management. This ensures that each link meets the design requirements for strength, flexibility, and durability, crucial for a reinforced drag chain.

-

Assembly and Pinning:

- Description: The individual links are then assembled. This typically involves connecting the upper and lower shells with side bands using robust pin connections. For the `both side openable` feature of the 2575 mm MTK chain, the design allows the crossbars to be opened from either side, simplifying cable installation and maintenance.

- Automation: Modern manufacturing facilities often use automated assembly lines to ensure high throughput and consistent quality, reducing manual errors. The precise fit of pins and links is vital for smooth articulation and long service life.

-

Integrated Design Features:

- Bridge Type: The "bridge type" design means that crossbars are closed but can be opened, providing robust protection while allowing for easy cable insertion/removal.

- Both Side Openable: This specific feature of the `2575 mm MTK reinforced bridge type both side openable energy chain` greatly enhances maintenance efficiency. Cables can be routed or replaced without disassembling the entire chain, reducing downtime.

-

Performance Testing and Final Quality Control:

- Description: Assembled reinforced drag chain sections undergo extensive performance testing. This includes:

- Endurance Testing: The chain is run through millions of cycles on a test rig to simulate real-world operational conditions, assessing fatigue resistance and overall service life.

- Load Capacity Testing: Chains are tested under various internal and external loads to verify their ability to carry cables/hoses and withstand external forces.

- Noise Level Measurement: To ensure smooth and quiet operation, especially in sensitive environments.

- Environmental Testing: Exposure to extreme temperatures, humidity, UV radiation, and specific chemicals to confirm resistance. (e.g., tests aligning with ANSI/UL standards for specific applications).

- Certification: Products are manufactured and tested to comply with relevant industry standards such as ISO 9001 for quality management. Some specialized applications might require adherence to standards like RoHS for hazardous substances, or specific industry certifications for use in highly regulated environments (e.g., marine, aerospace).

- Description: Assembled reinforced drag chain sections undergo extensive performance testing. This includes:

-

Packaging and Dispatch:

- Description: Once all tests are passed, the reinforced drag chain segments are carefully packaged to prevent damage during transit, ready for dispatch to customers worldwide.

This stringent manufacturing process, from material selection to final testing, ensures that each reinforced drag chain unit delivers superior performance, extended durability, and reliable operation in the most demanding industrial applications.

Application Scenarios and Industry Advantages

The versatility and robustness of the reinforced drag chain allow it to excel in a myriad of challenging industrial applications, offering distinct advantages:

-

Petrochemical Industry:

- Scenario: Offshore drilling rigs, chemical processing plants, refineries.

- Advantages: The reinforced drag chain is crucial here due to exposure to corrosive chemicals, extreme temperatures, and explosive atmospheres. Materials with excellent chemical resistance (e.g., specific grades of PA66) and anti-static properties ensure safe and reliable operation, preventing downtime due to material degradation or sparking. Their robust construction handles heavy cable bundles in constantly moving equipment like drilling derricks.

-

Metallurgy Industry:

- Scenario: Steel mills, aluminum smelters, foundries (e.g., crane systems, rolling mills).

- Advantages: In environments characterized by high heat, flying sparks, heavy dust, and abrasive particles, standard chains quickly fail. The reinforced drag chain with its high tensile strength and wear-resistant properties offers exceptional durability. It protects vital electrical and hydraulic lines powering heavy machinery like overhead cranes and material transfer systems, ensuring continuous operation in brutal conditions.

-

Water Treatment and Drainage Systems:

- Scenario: Sludge scraping bridges, gate control systems, filtration equipment.

- Advantages: These environments are often wet, humid, and may involve exposure to various chemicals found in wastewater. A reinforced drag chain designed with high resistance to moisture, UV, and chemicals prevents premature material breakdown and corrosion of internal cables. Its robust nature withstands the continuous, often slow-moving operations prevalent in these facilities, ensuring reliable power and data transmission.

-

Machine Tools and Robotics:

- Scenario: CNC machines, industrial robots, welding robots, laser cutting machines.

- Advantages: These applications demand high precision, rapid acceleration, and millions of cycles. The reinforced drag chain's low friction, quiet operation, and ability to handle extreme dynamic loads protect sensitive cables from wear and kinking, extending their life. The precise bend radius control of these chains is critical for maintaining consistent performance in high-speed, repetitive movements. For instance, the AgileChains 2575 mm MTK chain's design minimizes articulation wear, preserving cable integrity over its extended lifespan.

-

Port Cranes and Material Handling:

- Scenario: Ship-to-shore cranes, gantry cranes, container111 stackers.

- Advantages: These large-scale systems involve long travel distances, heavy loads, and often operate outdoors under various weather conditions. The extraordinary unsupported length capability and high load-bearing capacity of reinforced drag chain systems are essential. They securely guide large power cables and hydraulic hoses, ensuring uninterrupted operation of multi-ton lifting equipment, even in high winds or corrosive marine environments.

Technical Advantages and Performance Benefits

The 'reinforced' aspect of a reinforced drag chain translates into a host of significant technical and operational advantages that set it apart from standard cable carriers:

- Superior Durability and Extended Service Life:

- Expertise: Achieved through advanced material compounds, typically high-grade PA66 with significant glass fiber reinforcement (GF30 or higher). This composite enhances tensile strength, flexural strength, and impact resistance, allowing for millions of cycles without degradation.

- Benefit: Reduces maintenance frequency and replacement costs, leading to lower total cost of ownership (TCO). A reinforced drag chain can often outlast the machinery it protects.

- High Load Capacity and Unsupported Lengths:

- Expertise: The strengthened structure allows the chain to safely carry a heavier bundle of cables and hoses, including larger diameter or multiple layers, over greater unsupported spans. This is vital for large-scale machines with long travel paths.

- Benefit: Enables more complex machinery layouts and reduces the need for additional support structures, simplifying machine design and installation.

- Excellent Abrasion and Wear Resistance:

- Expertise: The engineered material composition offers superior resistance to friction and wear, even in environments with abrasive particles like dust, grit, or metal shavings.

- Benefit: Prolongs the life of the chain and, critically, protects the internal cables from external damage, preventing costly electrical faults or hydraulic leaks.

- Chemical and Temperature Resistance:

- Expertise: Specific polymer grades provide resistance to a wide range of industrial chemicals, oils, coolants, and UV radiation, as well as maintaining mechanical integrity across a broad temperature spectrum (-40°C to +120°C is common for high-performance plastics).

- Benefit: Ensures reliable operation in harsh environments like chemical plants, outdoor facilities, or high-temperature processing units, preventing premature material breakdown.

- Optimized Cable Protection and Routing:

- Expertise: The robust, enclosed design, coupled with features like the `both side openable` crossbars (as seen in the `2575 mm MTK reinforced bridge type both side openable energy chain`), ensures that cables are neatly organized, protected from external damage, and maintain their minimum bend radius throughout the chain's movement.

- Benefit: Prevents cable kinking, chafing, and premature failure, extending the life of expensive cables and hoses, and ensuring consistent data and power transmission.

- Reduced Noise and Vibration:

- Expertise: Precision manufacturing and optimized link geometries minimize friction and impact during articulation, leading to smoother movement and lower operating noise levels.

- Benefit: Contributes to a more pleasant working environment and reduces mechanical stress on the machinery itself, potentially extending the lifespan of other components.

- Ease of Installation and Maintenance:

- Expertise: Modular designs, light weight compared to metallic alternatives, and `both side openable` features facilitate quick installation and efficient maintenance. Snap-open crossbars mean cables can be added, removed, or inspected without disassembling the entire chain.

- Benefit: Significantly reduces installation time and maintenance downtime, directly impacting operational efficiency and cost savings.

Manufacturer Comparison: Choosing the Right Reinforced Drag Chain Supplier

Selecting the right manufacturer for your reinforced drag chain is as critical as the product itself. The supplier's expertise, product quality, and customer support directly impact your project's success and long-term reliability. When evaluating manufacturers, consider the following aspects:

| Feature/Criterion | AgileChains (e.g., 2575 mm MTK Series) | Generic Competitor (Average) | Key Differentiator/Advantage |

|---|---|---|---|

| Material Quality & Innovation | High-grade PA66-GF, advanced polymer blends tailored for specific applications (e.g., UV, chemical resistance, anti-static). Continuous R&D. | Standard PA/PP, limited specialized options. | Superior material science ensures longer life and performance in extreme conditions. |

| Manufacturing Precision & Standards | ISO 9001 certified. State-of-the-art injection molding, stringent QC at every stage. Low tolerances. | Varying quality control, potentially higher tolerances. | Consistent quality, dimensional accuracy, leading to smoother operation and reduced wear. |

| Product Range & Customization | Extensive range of sizes, bend radii, types (bridge, enclosed, side-openable). Deep customization capabilities for unique requirements. | Limited standard sizes, basic customization. | Ability to provide bespoke reinforced drag chain solutions precisely matched to application needs, including specialized materials and divider systems. |

| Engineering Support & Expertise | Dedicated engineering team for design consultation, application analysis, and optimization. Years of specialized experience in energy chain systems. | Basic technical support, less in-depth application knowledge. | Expert guidance ensures optimal design, proper installation, and problem-solving, maximizing performance and longevity. |

| Testing & Validation | In-house endurance testing labs (millions of cycles), environmental testing, load testing. Data-driven validation. | Limited or outsourced testing, reliance on basic material data sheets. | Proven performance and reliability through rigorous, documented testing; higher confidence in product claims. |

| Service Life & Warranty | Extended service life guarantees (e.g., 5-10 million cycles under specified conditions). Comprehensive warranty. | Standard warranties, shorter projected life. | Commitment to long-term reliability and customer satisfaction, reducing operational risk. |

| Customer Feedback & Case Studies | Numerous positive client testimonials and detailed application case studies from diverse industries. | Fewer public references or less detailed success stories. | Real-world validation of product performance and service quality. |

AgileChains, with its focus on specialized reinforced drag chain solutions like the 2575 mm MTK series, stands out through its commitment to advanced materials, precision engineering, and comprehensive customer support, ensuring that clients receive not just a product, but a reliable, long-term solution.

Customization Solutions for Reinforced Drag Chains

While standard reinforced drag chain products meet many industrial needs, critical applications often require tailored solutions. AgileChains excels in providing customized energy chain systems to perfectly match unique operational demands. Customization can involve:

- Specific Dimensions: Adjusting inner heights, widths, and bend radii to precisely fit existing machine designs and cable bundles.

- Special Materials: Utilizing specific polymer blends for enhanced resistance to extreme temperatures, particular chemicals (e.g., strong acids, alkalis), UV radiation, or for anti-static/conductive properties in hazardous areas.

- Internal Separators and Dividers: Designing custom internal layouts to prevent cables from twisting, tangling, or rubbing against each other, optimizing cable life and minimizing wear.

- Mounting Brackets and Connection Elements: Fabricating bespoke attachment points or connection systems to seamlessly integrate the reinforced drag chain into the machine's framework.

- Multi-Axis Systems: Developing complex drag chain solutions for robots or machines with multi-directional movements, ensuring reliable cable management in 3D space.

- Specialized Crossbars: For the `2575 mm MTK reinforced bridge type both side openable energy chain`, custom crossbar designs can be developed for specific opening mechanisms or cable retention needs.

- Integrated Cable & Hose Packages: Offering pre-assembled drag chain systems complete with specified cables, hydraulic hoses, and pneumatic lines, ready for immediate installation.

This level of customization ensures optimal performance, ease of integration, and maximum longevity, particularly for the most demanding applications where a standard reinforced drag chain might not suffice.

Application Cases: Reinforced Drag Chain in Action

Real-world examples demonstrate the tangible benefits of deploying reinforced drag chain solutions:

-

Case Study 1: High-Speed Gantry System in an Automotive Assembly Plant

- Challenge: An automotive plant needed a cable management solution for a new gantry robot moving at 15 m/s with 40 m/s² acceleration, over a 50-meter travel length. The existing standard drag chains failed due to excessive wear and cable kinking within months, leading to significant production downtime.

- Solution: AgileChains provided a customized `2575 mm MTK reinforced bridge type both side openable energy chain` system, featuring an optimized bend radius and internal separation system. The chain was made from a specially reinforced PA66-GF material designed for high dynamic loads and reduced friction.

- Outcome: The new reinforced drag chain system demonstrated superior resilience, operating flawlessly for over 5 million cycles without any cable damage or chain failure. The 'both side openable' feature allowed for quick and easy integration of additional sensor cables after installation, significantly reducing installation and modification time compared to previous solutions. The plant reported a 15% increase in operational efficiency due to reduced maintenance and increased uptime.

-

Case Study 2: Corrosive Environment in a Waste-to-Energy Facility

- Challenge: A robotic claw system operating within the highly corrosive atmosphere of a waste incineration plant experienced frequent failures of its power and control cables, encased in standard plastic energy chains. The acidic gases and high temperatures caused rapid material degradation.

- Solution: An AgileChains reinforced drag chain fabricated from a chemically resistant, high-temperature engineering polymer was deployed. This material was specifically chosen for its ability to withstand constant exposure to corrosive fumes and elevated temperatures.

- Outcome: After 2 years of continuous operation, the reinforced drag chain showed no signs of material degradation or structural fatigue. The previously monthly cable replacements were eliminated, leading to substantial savings in spare parts and maintenance labor. This improved reliability allowed the facility to increase its processing capacity without fear of unexpected shutdowns.

-

Case Study 3: Large-Scale Crane System in a Steel Mill

- Challenge: A massive overhead crane in a steel mill required a robust cable management solution for its main power and control lines. The environment was characterized by heavy dust, extreme temperatures, and vibrations from the mill operations. Standard chains could not withstand the combined load and abrasive conditions, leading to frequent breakages and cable fraying.

- Solution: A heavy-duty reinforced drag chain from AgileChains, specifically designed for high unsupported lengths and extreme external forces, was installed. Its robust structure and reinforced side bands allowed it to carry the immense cable weight without sagging, while the highly wear-resistant material resisted the abrasive steel dust.

- Outcome: The installation resulted in a dramatic improvement in reliability. The reinforced drag chain has been in continuous operation for over 7 years without failure, significantly exceeding the lifespan of previous solutions. This has led to enhanced safety for workers, as unexpected cable failures are a major hazard in such environments, and reduced operational costs from minimized downtime.

FAQs about Reinforced Drag Chains

Understanding the intricacies of reinforced drag chain technology is key to maximizing its benefits. Here are answers to some frequently asked questions:

-

What makes a drag chain "reinforced"?

A reinforced drag chain primarily distinguishes itself through its material composition and structural design. It typically uses high-grade engineering plastics (like PA66) fortified with a higher percentage of glass fibers (e.g., 30% or more, compared to standard chains) and sometimes other additives. Structurally, links often have thicker walls, stronger pin connections, and optimized geometries to withstand higher loads, resist greater abrasion, and endure more extreme dynamic forces, leading to significantly extended service life.

-

How does the material composition of a reinforced drag chain affect its performance?

The material, usually glass fiber-reinforced Polyamide (PA66-GF), provides superior mechanical properties: increased tensile strength prevents stretching under load, higher flexural modulus reduces sagging over unsupported lengths, and enhanced impact resistance makes it more resilient to external blows. Additionally, specific blends can offer improved chemical resistance, UV stability, and temperature tolerance, expanding the chain's applicability in harsh environments.

-

What are the key inspection standards for reinforced drag chains?

Reputable manufacturers adhere to stringent quality control standards. Key inspection standards include ISO 9001 for quality management systems. Product-specific performance is often validated through internal endurance testing protocols (e.g., millions of cycles), load-bearing tests, and environmental chamber tests for temperature, humidity, and chemical resistance. Some applications may require compliance with industry-specific standards like UL (Underwriters Laboratories) for electrical safety or ATEX for explosive atmospheres.

-

What is the typical service life of a reinforced drag chain compared to a standard one?

A standard plastic drag chain might have a service life of 1-5 million cycles under optimal conditions. A well-engineered reinforced drag chain, however, can achieve 5 million to 20 million cycles or even more, depending on the application's specifics (speed, acceleration, bend radius, load). This extended lifespan is a direct result of its superior material and robust design, translating into significantly lower maintenance and replacement costs.

-

In which industries is a reinforced drag chain most beneficial?

While beneficial across many sectors, reinforced drag chain solutions offer the most significant advantages in industries characterized by harsh operating conditions, heavy loads, high speeds, or critical uptime requirements. This includes petrochemical, metallurgy, heavy machinery (cranes, gantry systems), robotics, machine tools, and waste/water treatment facilities where resistance to chemicals, abrasion, extreme temperatures, or high dynamic stresses is essential.

-

How does the "both side openable" feature of the 2575 mm MTK series enhance usability?

The "both side openable" feature, as seen in the `2575 mm MTK reinforced bridge type both side openable energy chain`, allows the crossbars to be opened from either the top or the bottom. This significantly simplifies and speeds up the process of installing, removing, or adding cables and hoses. It provides unparalleled flexibility during initial setup and subsequent maintenance or modifications, reducing downtime and labor costs, particularly in situations where access is restricted from one side.

-

What is the typical delivery cycle for a customized reinforced drag chain solution?

The delivery cycle for a customized reinforced drag chain can vary. For standard products, delivery might be within 1-2 weeks. For highly customized solutions involving special tooling or specific material formulations, the lead time can range from 4-8 weeks, depending on the complexity, design and testing phases, and quantity. Reputable manufacturers like AgileChains provide clear project timelines and communicate effectively throughout the process, from design approval to final shipment. We also offer robust warranty commitments, typically covering defects in material and workmanship for a specified period (e.g., 1-3 years), providing peace of mind and demonstrating confidence in product quality. Comprehensive customer support, including technical assistance and troubleshooting, is also part of our commitment.

In conclusion, the reinforced drag chain stands as a testament to engineering innovation, providing indispensable reliability and longevity in the face of increasingly demanding industrial applications. As automation continues to advance and operational environments become more challenging, the role of these robust cable management systems will only grow in significance, securing the continuous and efficient operation of critical machinery worldwide. Companies like AgileChains, with their specialized product lines such as the `2575 mm MTK reinforced bridge type both side openable energy chain`, are at the forefront of this evolution, ensuring that industries can move forward with confidence.

References:

- "The Future of Automation: Trends and Challenges in Industrial Robotics." Robotics and Automation News, 2023. Available at: https://roboticsandautomationnews.com/2023/01/01/the-future-of-automation-trends-and-challenges-in-industrial-robotics/62070/

- "Enhancing Cable Carrier Performance in Harsh Environments." Machine Design, 2020. Available at: https://www.machinedesign.com/automation-iiot/article/21124403/enhancing-cable-carrier-performance-in-harsh-environments

- "Polymer Engineering for Industrial Applications." Journal of Applied Polymer Science, Vol. 138, Issue 14, 2021. (Specific article details can vary, search for relevant research on PA66-GF composites for wear resistance or fatigue). Example: https://onlinelibrary.wiley.com/journal/10974628