synchronous belt wheel

The Synchronous Belt Wheel A Key Component in Mechanical Systems

The synchronous belt wheel is an essential element in various mechanical systems, playing a critical role in the efficient transmission of power. Widely used in industries ranging from automotive to manufacturing, these wheels ensure that motion is conveyed smoothly and reliably between rotating components. Understanding the design, function, and applications of synchronous belt wheels can provide insights into their significance in engineering and technology.

Design and Functionality

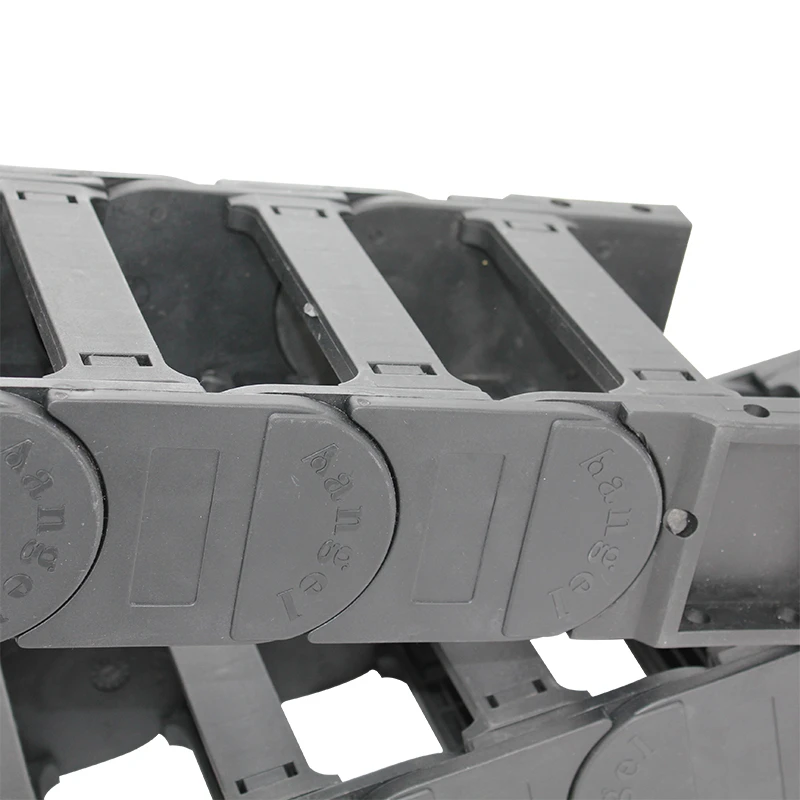

A synchronous belt wheel, often referred to as a timing pulley, is designed to mesh perfectly with a synchronous belt, which has teeth that fit into corresponding grooves on the wheel. This tooth-and-groove design is what sets synchronous belts apart from other belt types, allowing for precise timing between the driven and driving components. As the driving wheel turns, it pulls the belt along, transferring motion to the driven wheel in a synchronized manner. This synchronization eliminates slippage that can occur in traditional v-belt systems, making synchronous systems more efficient.

The construction of synchronous belt wheels typically involves durable materials such as aluminum or plastic, with high-tensile strength to withstand the stresses of operation

. The wheels come in various sizes and tooth configurations, allowing engineers to select the right components based on the specific requirements of their applications.Advantages of Synchronous Belt Wheels

One of the primary advantages of using synchronous belt wheels is their ability to maintain accurate timing in machinery. This is particularly important in applications where precise movements are critical, such as in automotive engines and robotics. The elimination of slippage leads to consistent performance and reduced wear on components, contributing to longer operational lifespan and lower maintenance costs.

synchronous belt wheel

Additionally, synchronous belt systems operate quietly compared to their chain or gear counterparts. This results in a more pleasant workplace environment, especially in high-volume operations. The flexibility in design also enables the integration of these systems into compact spaces, making them ideal for applications where space is a premium.

Applications in Various Industries

Synchronous belt wheels have diverse applications across multiple industries. In the automotive sector, they are essential for timing belts that connect the crankshaft to the camshaft, ensuring that both components operate in harmony. This precise timing is crucial for engine efficiency and performance.

In manufacturing, synchronous belts are commonly used in conveyor systems, where they facilitate the movement of goods from one area to another in a controlled manner. These systems can be found in assembly lines, food processing plants, and logistics operations. Furthermore, they are integral to robotics, allowing for the precise movement required for tasks such as assembly, packaging, and material handling.

Conclusion

The synchronous belt wheel is a vital component in modern mechanical systems, contributing to the efficiency and reliability of various applications. With their ability to provide precise timing, reduced slippage, and lower noise levels, these wheels have become indispensable in industries ranging from automotive to manufacturing. As technology continues to evolve, the importance of synchronous belt wheels in innovative mechanical designs will undoubtedly grow, reinforcing their status as a key player in the field of engineering and technology. By understanding and leveraging the advantages of synchronous belt wheels, engineers can create more effective and reliable systems that enhance productivity and performance in numerous applications.