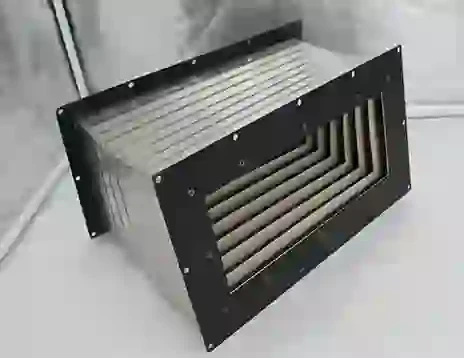

milling machine bellows

The Importance of Bellows in Milling Machines

Milling machines are intricate pieces of machinery that play a crucial role in the manufacturing and machining industries. They are designed to cut, shape, and finish metal, wood, and other materials with high precision. However, like any complex machine, they require proper protection and maintenance to ensure longevity and consistent performance. One essential component of a milling machine often overlooked is the bellow.

What Are Bellows?

Bellows are flexible, accordion-like structures that are primarily used to protect moving parts of machines from dust, debris, and liquid contaminants. They are typically made from materials such as rubber, polyurethane, or fabric, which offer excellent flexibility and durability. In the context of milling machines, bellows serve a critical function by safeguarding the machine's guides, tables, and other sensitive components.

Function and Benefits of Bellows in Milling Machines

1. Protection Against Contaminants One of the primary roles of bellows in milling machines is to shield internal components from harmful particles. During milling operations, metal shavings, dust, and coolant can accumulate around the machine. Without bellows, these contaminants could enter critical areas, leading to corrosion, reduced efficiency, and potential machinery failure.

2. Reduced Maintenance By preventing the ingress of foreign materials, bellows significantly reduce the need for regular maintenance. Machines with well-maintained bellows require less frequent cleaning and servicing, thereby saving time and operational costs.

3. Extended Lifespan of Components The longevity of milling machines largely depends on the condition of their internal components. By keeping these parts clean and protected, bellows help to preserve the machine's functionality over time. This protection translates into lower replacement and repair costs, making bellows a cost-effective investment.

4. Enhanced Safety Milling machines are inherently dangerous if not properly maintained. Bellows contribute to safety by minimizing the risk of accidents caused by machine malfunctions due to dirt or debris buildup. Well-maintained bellows can contribute to a safer working environment, reducing liability risks for manufacturers.

milling machine bellows

5. Improved Precision and Accuracy For industries that rely on precision machining, such as aerospace or automotive manufacturing, even the slightest amount of contamination can lead to defects. Bellows ensure that the precision of milling operations is maintained by eliminating the potential for critical measurement errors caused by dirt accumulation.

Types of Bellows Used in Milling Machines

There are several types of bellows utilized in milling machines, each designed for specific applications.

- Soft Bellows These are typically used in areas where flexibility is essential. They can expand and contract easily, making them suitable for moving parts of the machine.

- Rigid Bellows Often made from solid material, rigid bellows provide enhanced protection against heavier debris and are suitable for fixed parts.

- Custom-Built Bellows Many manufacturers opt for custom solutions tailored to their specific milling machine designs. Custom bellows can cater to unique operational needs and conditions.

Conclusion

In conclusion, bellows are a vital yet often underrated component of milling machines. They provide essential protection, enhance machine life, reduce maintenance, and improve safety and precision. As the manufacturing industry continues to demand higher standards and efficiency, the importance of investing in high-quality bellows cannot be overstated. Manufacturers and operators should prioritize regular inspections and maintenance of bellows to ensure their machines operate smoothly and effectively. By doing so, they can optimize performance and protect their investments in this essential equipment.