bellows boot covers

The Importance of Bellows Boot Covers

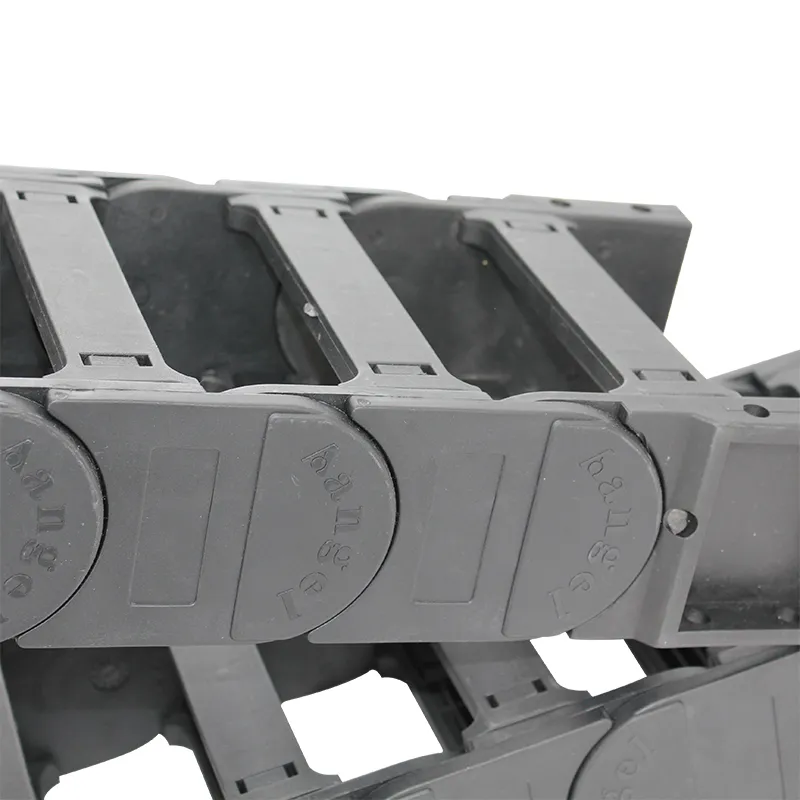

Bellows boot covers are essential components in numerous industrial applications, from automotive to robotics and heavy machinery. These flexible coverings serve to protect the intricate parts of machinery and equipment from dirt, dust, moisture, and other environmental contaminants that could impede their performance. This article will delve into the significance of bellows boot covers, their various applications, design considerations, and the materials commonly used in their production.

What are Bellows Boot Covers?

Bellows boot covers are typically made of elastic materials designed in a cylindrical or bellows shape, enabling them to expand and contract while maintaining a seal. They are often seen in applications where components need to move relative to each other, such as in suspension systems or telescoping mechanisms. By enveloping moving parts, bellows boot covers prevent foreign particulate matter from entering critical areas, thus extending the lifespan and functionality of the equipment.

Applications

The applications of bellows boot covers are diverse. In the automotive industry, they play a crucial role in protecting the joints in steering and suspension systems. For instance, they are commonly found on the CV (constant velocity) joint boots, where their robust structure shields the joint from environmental exposure that could lead to premature wear.

In the realm of robotics, bellows boot covers protect sensitive actuators and joints from dust and debris, ensuring smooth operation in environments like factories or harsh outdoor settings. Furthermore, in industrial machinery, these protective covers safeguard hydraulic and pneumatic cylinders, allowing them to function efficiently without external contamination.

Design Considerations

When designing bellows boot covers, several factors need to be considered to ensure optimal performance. First and foremost is the size and fit. The cover must be precisely sized to the components it protects while allowing for sufficient flexibility to accommodate movement. An ill-fitting cover can lead to leaks, exposing crucial parts to damaging elements.

Another critical factor is the application-specific load requirements. Bellows boot covers must be able to endure the specific loads they will encounter, such as axial tension and compression. Therefore, they should be tested for durability and resistance to common wear and tear over time.

bellows boot covers

Material Selection

The materials used in the manufacturing of bellows boot covers can significantly influence their performance and longevity. Common materials include rubber, thermoplastic elastomers (TPE), and PTFE (polytetrafluoroethylene).

- Rubber is a popular choice due to its excellent elasticity and resistance to wear and tear. However, it may not perform well in extreme temperatures and could degrade under certain chemical exposures.

- Thermoplastic elastomers (TPE) offer a balance of flexibility and chemical resistance, making them suitable for various applications, including automotive and industrial use. TPEs are also lightweight and can be molded into various shapes, making them versatile for customized designs.

- PTFE is known for its exceptional resistance to heat and chemicals, making it ideal for more specialized applications that may involve corrosive substances or extreme temperatures. However, PTFE bellows can be more expensive to produce compared to other materials.

Maintenance and Replacement

Regular inspection and maintenance of bellows boot covers are crucial to ensure they perform their protective functions effectively. Over time, wear and environmental exposure can lead to tears, cracks, or degradation. Identifying damage early can prevent more significant issues, such as contamination of the components they protect.

When replacing bellows boot covers, selecting the right type for the application is vital. Using covers that are not designed for the specific environment or load can lead to premature failure and increased costs.

Conclusion

Bellows boot covers play an indispensable role in protecting the moving parts of machines across various industries. Their ability to shield sensitive components from environmental contaminants not only extends the life of the equipment but also ensures optimal performance. With careful consideration given to design, material selection, and maintenance, bellows boot covers can significantly enhance the durability and reliability of machinery, making them a critical component in the modern industrial landscape. As technology continues to evolve, the development of more advanced bellows boot covers will likely lead to even greater efficiencies in protecting vital components across diverse applications.