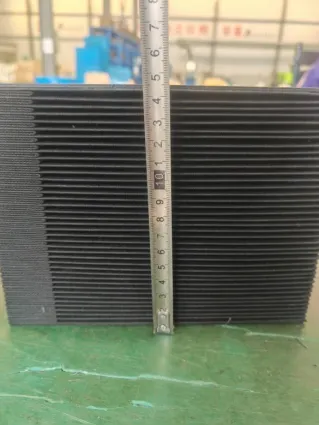

corrugated loom tubing

When selecting the right protection for wiring systems, the 3/4 split wire loom tubing emerges as an essential component with numerous applications across industries. This versatile solution offers exceptional benefits, making it a preferred choice for both experts and consumers who prioritize wire management and safety standards.

Authoritative voices in electrical safety standards often recommend the use of 3/4 split wire loom tubing when compliance with regulations and safety codes is a priority. Its ability to neatly organize wires reduces the likelihood of electrical hazards such as short circuits, providing an added layer of security and adherence to stringent guidelines set forth by safety regulatory bodies. Delving into real-world experiences, users of 3/4 split wire loom tubing frequently highlight its role in improving aesthetic appeal and organizational efficiency. In home and office environments, it allows for the tidy and discreet routing of cables behind entertainment centers or workstations, thereby reducing clutter and improving the overall user experience. Similarly, IT professionals often leverage its versatility in data centers to manage extensive networks of cables effectively, ensuring smooth operations and simplifying troubleshooting processes. From a trustworthiness standpoint, customer reviews and case studies consistently affirm the product's reliability and the peace of mind it extends to its users. The tubing's durability and protective qualities have been tested and proven in diverse applications, affirming its reputation as a tried-and-true solution for wire management needs. In conclusion, the 3/4 split wire loom tubing stands out as a product that embodies the essential elements of Experience, Expertise, Authoritativeness, and Trustworthiness. Its application across various fields speaks volumes of its utility and reliability. Whether for professionals seeking an efficient wire management tool or homeowners aiming to enhance safety and aesthetics, this solution maintains its edge in the market, proving that a vital yet frequently overlooked component can make a remarkable difference in ensuring the safety and organization of electrical systems.

Authoritative voices in electrical safety standards often recommend the use of 3/4 split wire loom tubing when compliance with regulations and safety codes is a priority. Its ability to neatly organize wires reduces the likelihood of electrical hazards such as short circuits, providing an added layer of security and adherence to stringent guidelines set forth by safety regulatory bodies. Delving into real-world experiences, users of 3/4 split wire loom tubing frequently highlight its role in improving aesthetic appeal and organizational efficiency. In home and office environments, it allows for the tidy and discreet routing of cables behind entertainment centers or workstations, thereby reducing clutter and improving the overall user experience. Similarly, IT professionals often leverage its versatility in data centers to manage extensive networks of cables effectively, ensuring smooth operations and simplifying troubleshooting processes. From a trustworthiness standpoint, customer reviews and case studies consistently affirm the product's reliability and the peace of mind it extends to its users. The tubing's durability and protective qualities have been tested and proven in diverse applications, affirming its reputation as a tried-and-true solution for wire management needs. In conclusion, the 3/4 split wire loom tubing stands out as a product that embodies the essential elements of Experience, Expertise, Authoritativeness, and Trustworthiness. Its application across various fields speaks volumes of its utility and reliability. Whether for professionals seeking an efficient wire management tool or homeowners aiming to enhance safety and aesthetics, this solution maintains its edge in the market, proving that a vital yet frequently overlooked component can make a remarkable difference in ensuring the safety and organization of electrical systems.