Flexible Wire Loom for Enhanced Protection and Organization of Cables and Wires

Understanding Protective Wire Loom A Comprehensive Guide

In the realm of electrical engineering and automotive industries, ensuring the safety and longevity of wiring systems is paramount. One effective solution to this challenge is the use of protective wire loom. This vital component serves multiple purposes, providing not only protection but also organization for various wiring applications.

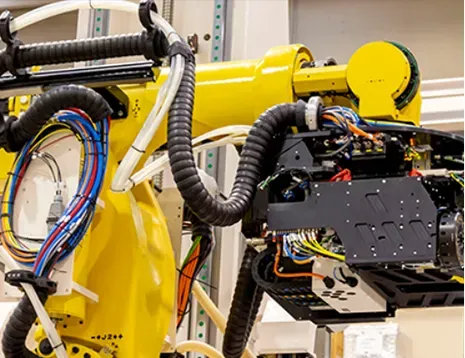

Protective wire loom, often made from materials such as polyethylene, nylon, or even rubber, is designed to shield wires from abrasions, heat, and environmental hazards. By encasing wires in a protective sheath, wire loom prevents wear and tear that could lead to short circuits or electrical failures. This is particularly crucial in automotive settings, where exposure to elements like dirt, moisture, and vibrations can compromise electrical systems.

One of the key advantages of using protective wire loom is its ability to manage wiring clutter. In complex electrical systems, especially within vehicles, wires can easily become tangled or disorganized. Wire loom provides a structured approach to routing wires, making it easier for technicians to access specific components during maintenance or repair. This not only saves time but also enhances the overall efficiency of electrical installations.

protective wire loom

In addition to organizational benefits, protective wire loom also contributes to fire safety. By providing a layer of insulation, it reduces the risk of wires overheating and igniting nearby flammable materials. This function is especially important in environments with high electrical loads, where the potential for overheating is significant.

Another noteworthy feature of protective wire loom is its flexibility. Available in various sizes and diameters, it can accommodate different wire gauges and configurations. This versatility makes it suitable for a wide range of applications, from household electronics to heavy machinery. Moreover, many types of wire loom come with features like expandable designs, allowing users to add or remove wires with ease.

When it comes to installation, protective wire loom is user-friendly. It can be cut to the desired length and easily slid over existing wire bundles. For added security, many people use tape or snap-on connectors to secure the ends, ensuring that wires remain protected throughout their lifespan.

In conclusion, protective wire loom is an indispensable tool in safeguarding wires from damage, enhancing organization, and ensuring safety in various wiring applications. As technology continues to evolve, the importance of such protective measures will only grow, making wire loom a fundamental element in the design and maintenance of electrical systems. Its benefits are clear, making it a wise investment for anyone involved in electrical installations or repairs.