Flexible Bellows Covers for Machinery Protection and Enhanced Performance Solutions

The Importance of Machine Way Cover Bellows in Precision Engineering

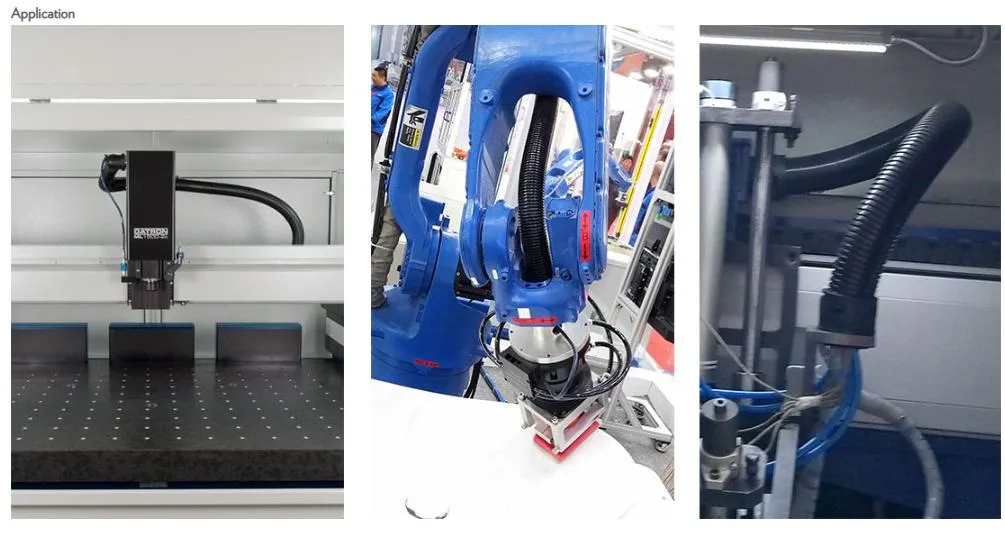

In the world of precision engineering and manufacturing, protecting vital components of machinery is paramount. Among various protective solutions, machine way cover bellows play a crucial role in safeguarding critical parts from contaminants such as dust, chips, and coolant. These flexible protective coverings are integral to ensuring the longevity and optimal performance of machinery, particularly in CNC (Computer Numerical Control) machines and conventional milling operations.

What are Machine Way Cover Bellows?

Machine way cover bellows are specially designed protective covers that shield the ways of machines - the surfaces along which moving parts glide. The primary function of these bellows is to keep debris, moisture, and harmful substances away from delicate components, thereby minimizing wear and tear. Made from durable materials such as rubber, polyurethane, or PVC, these bellows can withstand hostile environments and high levels of mechanical stress.

Their design allows for considerable flexibility and movement, which is essential in machines that have multiple axes of motion. As the machine operates, the bellows expand and contract, creating a barrier without hindering functionality. This flexibility also facilitates easy installation and maintenance, crucial in a manufacturing setup where downtime translates to lost productivity.

The Benefits of Using Way Cover Bellows

The benefits of incorporating machine way cover bellows into manufacturing processes are manifold

1. Protection Against Contaminants The primary benefit is their ability to guard against particles, fluids, and any foreign substances that could degrade machine performance. By keeping the ways clean, they ensure that the machinery operates smoothly, reducing the risk of jams and errors associated with debris accumulation.

machine way cover bellows

2. Reduced Maintenance Costs With consistent protection from contaminants, machines experience less wear, leading to lower maintenance and repair costs over time. This prolongs the lifespan of precision machinery, which is often a significant investment for manufacturers.

3. Improved Safety Machine way cover bellows contribute to a safer working environment. By preventing debris from exploding outwards during operation, they protect operators and nearby personnel from potential injuries.

4. Enhanced Accuracy Precision machinery relies on incredibly tight tolerances. By ensuring a contamination-free environment, way cover bellows help maintain the accuracy of machining operations, which is crucial in industries such as aerospace, automotive, and medical device manufacturing.

5. Versatility These bellows can be customized to fit virtually any machine design, regardless of size or shape. Their adaptability makes them suitable for a wide range of industrial applications.

Conclusion

In conclusion, machine way cover bellows are a small but vital component of the machinery ecosystem in precision engineering. Their protective qualities not only enhance the longevity and reliability of machines but also contribute significantly to a safer and more efficient working environment. As industries continue to evolve, the importance of investing in high-quality way cover bellows becomes increasingly clear.

Manufacturers that prioritize the protection of their assets with reliable bellows will likely experience improved operational efficiency and reduced long-term costs. Thus, as the demand for precision engineering grows, so too does the necessity for advanced protective solutions like machine way cover bellows, ensuring that technology and innovation continue to thrive in a demanding industrial landscape.