1 inch wire loom

Understanding 1-Inch Wire Loom Applications and Benefits

When it comes to maintaining organization and protection in electrical wiring, one component stands out wire loom. Specifically, 1-inch wire loom has gained popularity for its versatility and effectiveness in various applications. This article aims to explore the advantages, uses, and tips for working with 1-inch wire loom, shedding light on why it's a go-to choice for electricians, hobbyists, and DIYers alike.

What is Wire Loom?

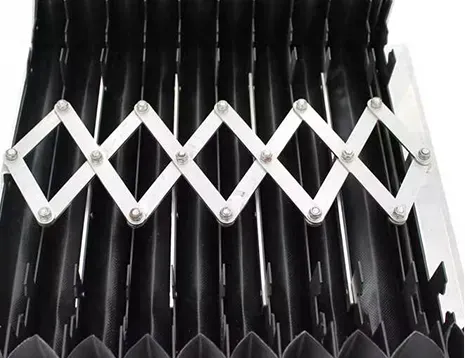

Wire loom, also known as wire loom tubing, is a protective sheathing used to bundle and organize wires and cables. Made from materials such as polyethylene, nylon, or PVC, wire loom is designed to shield wires from abrasion, heat, and environmental factors. The 1-inch variant refers to the diameter of the loom, making it suitable for accommodating larger bundles of wires.

Key Benefits of 1-Inch Wire Loom

1. Protection Against Damage One of the primary functions of wire loom is to protect wiring from physical damage. The 1-inch size provides ample space for multiple cables, safeguarding them from abrasion, cuts, and chemical exposure. This protective casing ensures that wires can withstand harsh conditions, prolonging their lifespan.

2. Organization and Aesthetics A clutter of wires can be unsightly and chaotic. The use of 1-inch wire loom helps in keeping cables organized, making it easier to identify and trace them. This organization not only improves aesthetics but also enhances productivity, as workers can quickly locate specific wires without searching through a tangled mess.

3. Flexibility and Ease of Installation 1-inch wire loom is flexible enough to bend and curve around tight spaces, making installation straightforward in various settings. Whether it's in an automotive environment, home theater setup, or DIY electronics project, the flexibility allows for easy routing of cables without compromising protection.

4. Variety of Applications From automotive wiring to residential electrical systems, 1-inch wire loom serves an array of applications. It can be utilized in industries such as telecommunications, manufacturing, and marine, where reliable protection of electrical components is crucial. Its adaptability makes it a favorite among professionals and hobbyists alike.

1 inch wire loom

5. Cost-Effectiveness Protecting wiring can save expenses in the long run by minimizing damage and reducing the need for repairs or replacements. The affordability of 1-inch wire loom compared to the potential costs associated with damaged wiring is a compelling reason for its widespread use.

Tips for Using 1-Inch Wire Loom

1. Selection of Material When choosing 1-inch wire loom, consider the environment in which it will be used. For example, nylon looms offer better resistance to heat and chemicals, while polyethylene may suffice for general indoor applications.

2. Cutting and Sizing Measure the length of wires accurately and cut the loom accordingly. It’s important to ensure that the loom fits snugly over the cables while allowing some room for movement and flexibility.

3. Securing the Loom To prevent the loom from sliding off, consider using electrical tape or zip ties at intervals along the loom. This helps maintain organization and integrity, especially in high-mobility environments like vehicles.

4. Avoiding Overcrowding While it may be tempting to bundle as many wires as possible into the 1-inch loom, overcrowding can lead to overheating and damage. Assess the number of cables and their capacity to ensure safety and functionality.

Conclusion

In conclusion, 1-inch wire loom serves as a crucial component in the realm of electrical safety and organization. With its protective features, flexibility, and cost-effectiveness, it facilitates the bundling and management of wires across various applications. Whether you are a professional electrician or an enthusiastic DIYer, integrating 1-inch wire loom into your projects will undoubtedly enhance both the safety and appearance of your wiring setups.