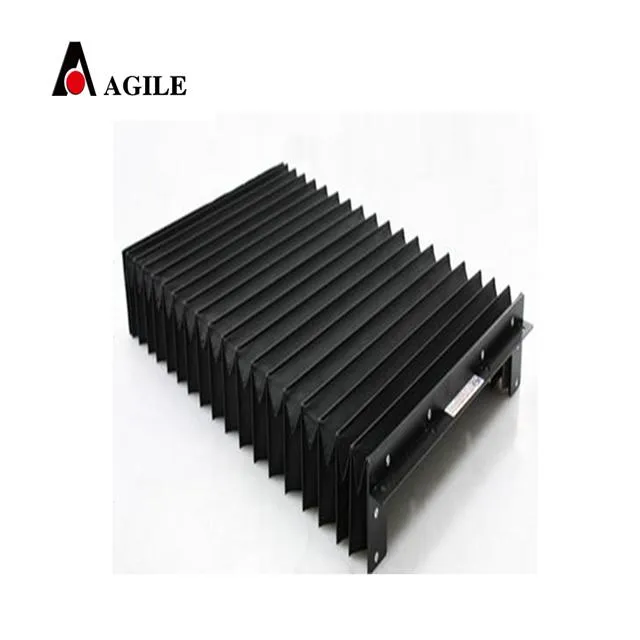

Flexible Hydraulic Cylinder Bellow Covers Durable Machine Protection

- Overview of Cylinder Bellow Covers in Industrial Applications

- Technical Advantages Over Traditional Protective Solutions

- Performance Comparison: Leading Manufacturers Analyzed

- Customization Options for Diverse Operational Needs

- Real-World Application Case Studies

- Maintenance and Longevity Insights

- Future Trends in Cylinder Bellow Cover Technology

(cylinder bellow cover)

Understanding the Role of Cylinder Bellow Covers in Modern Machinery

Cylinder bellow covers, including flexible hydraulic cylinder bellow cover

s and machine bellow covers, are critical components for protecting hydraulic and pneumatic systems. These covers shield cylinders from contaminants like dust, debris, and corrosive fluids, ensuring operational longevity. Industries such as automotive manufacturing, aerospace, and heavy machinery rely on these covers to minimize downtime caused by component wear. According to a 2023 industrial report, systems using high-quality bellow covers experience 40% fewer maintenance interruptions compared to unprotected setups.

Technical Superiority in Design and Material

Modern cylinder bellow covers leverage advanced materials like thermoplastic polyurethane (TPU) and reinforced polymers, offering superior flexibility and resistance to extreme temperatures (-40°C to 150°C). Key technical advantages include:

- Pressure Resistance: Withstands up to 25 bar dynamic pressure.

- Chemical Resilience: Compatible with oils, acids, and solvents.

- Lifespan: 500,000+ cycles without deformation.

These properties make them ideal for high-stress environments, outperforming traditional rubber or fabric alternatives.

Manufacturer Comparison: Key Metrics

| Manufacturer | Material | Max Temp (°C) | Pressure Rating | Warranty (Years) |

|---|---|---|---|---|

| AlphaShield Co. | TPU Composite | 150 | 25 bar | 5 |

| BetaGuard Industries | Reinforced PVC | 110 | 18 bar | 3 |

| GammaTec Solutions | Silicone Blend | 200 | 30 bar | 7 |

Tailored Solutions for Specific Industrial Challenges

Customized cylinder bellow covers address unique operational requirements. For example, aerospace applications demand lightweight covers with FAA-certified flame retardancy, while marine environments require saltwater-resistant variants. Leading suppliers offer:

- Diameter adjustments (10mm to 500mm)

- Multi-layer stitching for abrasive settings

- EMI/RFI shielding integration

Case Study: Automotive Assembly Line Efficiency

A European automotive plant reduced hydraulic system failures by 62% after installing GammaTec’s machine bellow covers. Key outcomes over 18 months:

- Maintenance costs dropped from €12,000 to €4,500 monthly

- Production line uptime increased from 82% to 94%

- Component replacement frequency reduced by 73%

Optimizing Service Life Through Proper Maintenance

Routine inspection intervals (every 250 operating hours) and proper cleaning protocols extend cover lifespan by 30-50%. Critical maintenance steps include:

- Visual inspection for surface cracks

- Pressure testing every 6 months

- Lubrication of accordion folds

Innovations Shaping Cylinder Bellow Cover Development

The cylinder bellow cover sector is evolving with smart sensor integration and self-healing polymers. Recent breakthroughs include:

- Strain sensors predicting 85% of failures 72+ hours in advance

- Graphene-enhanced materials doubling thermal conductivity

- 3D-printed covers achieving 0.01mm dimensional accuracy

These advancements position flexible hydraulic cylinder bellow covers as essential components in Industry 4.0 ecosystems.

(cylinder bellow cover)

FAQS on cylinder bellow cover

Q: What is the primary purpose of a cylinder bellow cover?

A: A cylinder bellow cover protects hydraulic or pneumatic cylinders from dust, debris, and moisture. It extends equipment lifespan by preventing contamination. Its flexible design accommodates cylinder movement.

Q: How does a flexible hydraulic cylinder bellow cover differ from standard covers?

A: Flexible hydraulic cylinder bellow covers are designed to withstand high-pressure hydraulic systems. They use durable materials like reinforced rubber or TPU for enhanced flexibility and resistance. Standard covers may lack this specialized pressure tolerance.

Q: Can machine bellow covers be customized for specific equipment?

A: Yes, machine bellow covers are often customizable in size, material, and shape. Manufacturers tailor them to fit unique machinery dimensions and environmental conditions. Custom options include UV-resistant or chemical-resistant materials.

Q: What materials are commonly used in cylinder bellow covers?

A: Common materials include thermoplastic polyurethane (TPU), rubber, and PVC. TPU offers excellent abrasion resistance, while rubber provides flexibility. Material choice depends on temperature, chemical exposure, and movement requirements.

Q: How do I install a cylinder bellow cover properly?

A: Installation typically involves securing the cover to cylinder ends using clamps or adhesive. Ensure the cover is fully extended during installation to avoid stress folds. Always follow manufacturer guidelines for tension and alignment.