Innovative Linear Rail Bellow Covers for Enhanced Protection and Performance

The Importance of Linear Rail Bellow Covers in Machinery

In the world of precision engineering and manufacturing, the durability and functionality of machinery play a pivotal role in ensuring efficiency and quality. Among the various components that contribute to the longevity and performance of machinery, linear rail bellow covers stand out as essential elements. These protective covers, designed to shield linear guides and rails from external contaminants, are vital for maintaining the integrity of machines in diverse industrial applications.

Linear rail bellow covers serve multiple purposes. First and foremost, they provide a barrier against dirt, dust, debris, and other environmental pollutants that can lead to premature wear of linear motion systems. In applications where machinery operates in harsh environments, such as factories, workshops, and outdoor settings, the exposure to various contaminants can be detrimental. By investing in high-quality bellow covers, companies can significantly reduce maintenance costs and downtime associated with repairs and replacements.

Moreover, these covers also prevent moisture ingress, which is particularly important in humid environments or applications where coolant fluids are used. Moisture can corrode metal components and lead to failure, making bellow covers a critical protective element in enhancing the lifespan of linear guides. The material used for these covers often varies, allowing for customization based on specific operational needs. Common materials include rubber, polyurethane, and other durable polymers that can withstand wear and environmental stressors.

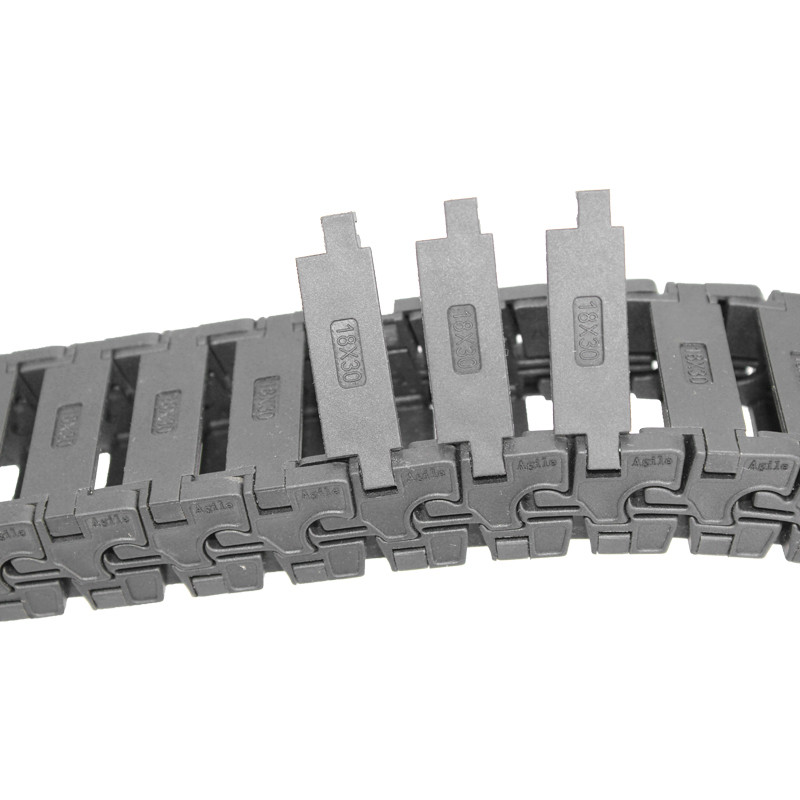

linear rail bellow cover

The design of linear rail bellow covers is another crucial aspect. These covers come in various shapes and sizes, ensuring that they fit snugly around the linear rails and guides. This tight fit not only enhances protection but also minimizes the chances of accidental disengagement during machine operation. Furthermore, many modern bellow covers offer flexibility, allowing for smooth movement of the linear motion systems without hindrance.

Another significant advantage of using linear rail bellow covers is their contribution to safety. By containing oils, lubricants, and other potentially hazardous materials, these covers can prevent slips, falls, and other workplace accidents. Keeping the working area clean and free of spills is essential for maintaining a safe working environment, and bellow covers play a vital role in this aspect.

In the realm of advanced manufacturing and automation, the precision of linear motion systems cannot be overstated. Therefore, the requirement for reliable and effective bellow covers becomes even more pronounced. Utilizing bellow covers that meet or exceed industry standards ensures not only operational efficiency but also enhances the overall performance of automated systems.

In conclusion, linear rail bellow covers are indispensable components in the functionality and maintenance of machinery. Their ability to protect against contaminants, prevent moisture damage, ensure safety, and extend the lifespan of linear motion systems makes them a critical investment for any business involved in precision engineering. As industries continue to evolve, the significance of these protective covers will undoubtedly grow, underscoring the need for high-quality materials and innovative designs to meet the ever-increasing demands of modern manufacturing.