VMTK 68x300mm Reinforced Nylon Flexible Bridge Drag Chain

The Backbone of Modern Automation: An Introduction to Advanced Cable Management

In the rapidly evolving landscape of industrial automation, the uninterrupted and protected flow of energy and data is paramount. High-performance cable management systems are no longer a mere accessory but a critical component ensuring operational continuity and machine longevity. Among these, drag chains stand out as indispensable solutions for guiding and protecting cables and hoses in dynamic applications. This detailed exposition delves into the engineering marvel that is the 68300 mm VMTK flexible bridge type reinforced nylon drag chain, a product engineered to meet the stringent demands of contemporary industrial environments. We will explore its technical specifications, manufacturing precision, diverse applications, and the distinct advantages it offers in enhancing system reliability and reducing total cost of ownership. Understanding the nuances of such advanced components is crucial for B2B decision-makers seeking to optimize their operational efficiency and safeguard vital investments.

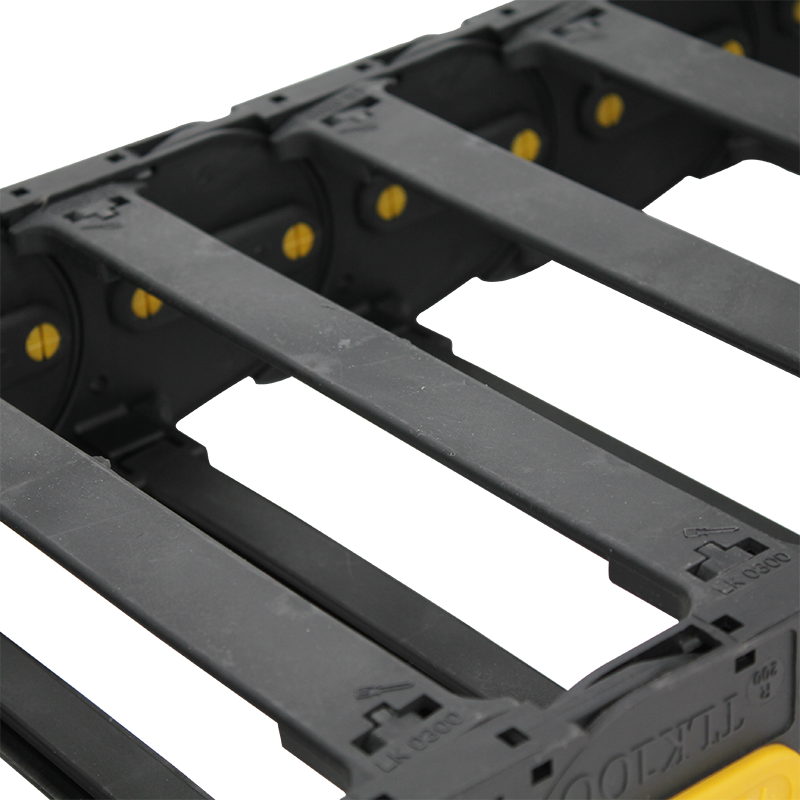

The drive for increased automation across sectors—from robotics and CNC machining to material handling and logistics—necessitates robust infrastructure capable of enduring continuous motion, environmental stressors, and mechanical fatigue. Industry trends consistently point towards a demand for lighter, stronger, and more versatile cable carrier systems that can facilitate higher speeds, greater accelerations, and longer unsupported lengths. The design and material selection of the 68300 mm VMTK flexible bridge type reinforced nylon drag chain directly address these trends, providing an optimal balance of flexibility, durability, and protective capability. Its innovative bridge-type design ensures easy access for cable insertion and maintenance, while the reinforced nylon composition guarantees exceptional resilience against wear, chemicals, and extreme temperatures, making it a cornerstone for future-proof industrial setups.

Engineering Excellence: Decoding the `68300 mm VMTK` Specifications

The nomenclature of the 68300 mm VMTK flexible bridge type reinforced nylon drag chain provides critical insights into its design and capabilities. The "68300 mm" refers to the internal dimensions, specifically an internal height of 68mm and an internal width of 300mm. These dimensions dictate the maximum bundle size of cables and hoses that can be accommodated, offering ample space for a wide array of industrial applications requiring substantial power and data transmission. The "VMTK" designation typically indicates a specific series within a manufacturer's product line, often signifying enhanced performance characteristics such as optimized bend radius, increased unsupported length capabilities, or specialized material compositions tailored for high-duty cycles. This particular series is renowned for its robust articulation and smooth operation, minimizing friction and wear on enclosed conductors.

The "flexible bridge type" design is a significant technical advantage. Unlike enclosed drag chains, the bridge-type offers open access to the cable compartment from the top. This feature vastly simplifies the installation, inspection, and maintenance of cables and hoses, enabling quick modifications or replacements without dismantling the entire chain. This flexibility translates directly into reduced downtime and labor costs, critical factors in lean manufacturing and continuous operation environments. Furthermore, the selection of "reinforced nylon" as the primary material underscores a commitment to durability and longevity. Typically, this involves high-grade polyamide (PA6) reinforced with glass fibers, which dramatically enhances tensile strength, impact resistance, and wear characteristics. This composite material ensures that the 68300 mm VMTK flexible bridge type reinforced nylon drag chain can withstand aggressive operating conditions, including exposure to lubricants, coolants, and varying temperatures, maintaining structural integrity over millions of cycles.

Manufacturing Precision: The Craftsmanship Behind Durability

The exceptional performance of the 68300 mm VMTK flexible bridge type reinforced nylon drag chain is rooted in a meticulously controlled manufacturing process, predominantly injection molding. This advanced polymer processing technique ensures consistent quality and precise dimensional accuracy for each link. High-grade reinforced nylon pellets are melted and injected under high pressure into precision-engineered molds. This process is critical for achieving the complex geometries required for drag chain links, including intricate pivot points and robust internal structures. Post-molding, components undergo stringent quality checks for dimensional conformity, surface finish, and material integrity, ensuring that each link contributes optimally to the chain's overall performance and longevity. The choice of injection molding, as opposed to traditional metalworking methods like casting or forging, allows for lightweight yet incredibly strong components that are naturally corrosion-resistant and self-lubricating.

Adherence to international standards is a non-negotiable aspect of the manufacturing process. Products like the 68300 mm VMTK flexible bridge type reinforced nylon drag chain are typically manufactured under ISO 9001 certified quality management systems, guaranteeing traceability and consistent quality. Furthermore, performance testing often aligns with industry-specific standards such as those from DIN (Deutsches Institut für Normung) or ANSI (American National Standards Institute), ensuring reliability under specified operating conditions. Critical parameters such as maximum unsupported length, bend radius, tensile strength, and abrasion resistance are rigorously tested in simulated operational environments. This comprehensive testing ensures a projected service life measured in millions of cycles, providing users with confidence in their long-term investment. The inherent properties of reinforced nylon, combined with precision manufacturing, also contribute to energy efficiency by minimizing frictional losses and reducing the overall load on machinery, especially in high-speed or long-travel applications.

Comprehensive Technical Specifications

To fully appreciate the capabilities of the 68300 mm VMTK flexible bridge type reinforced nylon drag chain, a detailed understanding of its technical parameters is essential. The following table consolidates key specifications, providing a clear overview of its performance characteristics and suitability for demanding industrial applications. These parameters are crucial for engineers and system integrators to ensure optimal selection and integration into their machinery.

| Parameter | Specification | Significance |

|---|---|---|

| Internal Height (Hi) | 68 mm | Determines maximum cable/hose diameter; ample space for large bundles. |

| Internal Width (Wi) | 300 mm | Defines the total width available for cable arrangement and segregation. |

| Material | Reinforced Nylon (PA6+GF) | High strength, wear resistance, chemical resistance, low friction. |

| Min. Bend Radius (R) | Typically 100-250 mm | Smallest permissible bend for installation; affects cable service life. |

| Max. Travel Speed | Up to 10 m/s | Suitable for high-speed automated machinery and robotic applications. |

| Max. Acceleration | Up to 50 m/s² | Withstands rapid changes in motion, crucial for dynamic systems. |

| Operating Temperature | -40°C to +120°C | Ensures reliable performance across diverse climate and operational conditions. |

| Unsupported Length | Up to 3-5 meters (varies with fill weight) | Critical for applications with long travel paths without support structures. |

| Service Life | Typically 5-10 million cycles | Indicates long-term reliability and reduced maintenance frequency. |

| Noise Level | Low (optimized link design) | Contributes to a quieter working environment, important for certain industries. |

Versatile Applications Across Core Industries

The robust design and superior material properties of the 68300 mm VMTK flexible bridge type reinforced nylon drag chain make it an ideal solution across a multitude of demanding industrial sectors. In the machine tool industry, these drag chains are indispensable for protecting power, data, and coolant lines on CNC machines, lathes, and milling centers, where high speeds and constant motion are the norm. Their ability to manage multiple lines within a confined space while ensuring precise bending radii is critical for maintaining tool accuracy and preventing cable fatigue. Similarly, in robotics, from articulated arms to gantry robots, they provide compact and reliable cable guidance, allowing for complex multi-axis movements without entanglement or damage.

Beyond traditional manufacturing, the petrochemical industry leverages such drag chains for their exceptional resistance to corrosive chemicals, oils, and high temperatures, ensuring reliable operation in harsh outdoor or processing plant environments. In material handling and logistics, particularly in automated storage and retrieval systems (AS/RS) and conveyor lines, the durability and long unsupported spans of the 68300 mm VMTK flexible bridge type reinforced nylon drag chain contribute significantly to system uptime and safety. For water and wastewater treatment (give-and-drainage) facilities, the drag chains' resistance to moisture and various chemical agents ensures long-term integrity of sensor and control cables in typically humid or chemically active settings. Furthermore, their low-noise operation makes them suitable for applications in clean rooms and medical equipment, where operational quietness and cleanliness are paramount. The inherent design promotes energy efficiency by reducing friction and ensuring smooth, reliable movement of cables, thereby minimizing power consumption associated with the drag chain's operation.

Strategic Advantages of the VMTK Series

Choosing the 68300 mm VMTK flexible bridge type reinforced nylon drag chain offers a distinct competitive edge through several key technical advantages. Firstly, its reinforced nylon composition provides an outstanding strength-to-weight ratio, allowing for lighter machine designs without compromising structural integrity or load-bearing capacity. This material also exhibits superior abrasion resistance and self-lubricating properties, which significantly extend the service life of both the drag chain and the enclosed cables/hoses by minimizing friction and wear. The inherent corrosion resistance and UV stability of reinforced nylon ensure reliable performance in challenging environments, from corrosive industrial atmospheres to outdoor applications exposed to direct sunlight.

The "flexible bridge type" design not only facilitates easy installation and maintenance but also contributes to reduced operational noise. Optimized link geometry and material properties ensure smooth articulation, leading to quieter operation, which is increasingly important in sensitive industrial or even office-like environments. Furthermore, the design inherently reduces stress on cables, minimizing bending fatigue and extending cable service life, thus preventing costly downtime associated with cable failures. From an energy efficiency perspective, the low friction coefficients of nylon contribute to lower drive power requirements for the machinery, translating into tangible energy savings over the operational lifespan. Rigorous internal testing and external certifications, often reflecting millions of trouble-free cycles, validate the reliability and durability of the 68300 mm VMTK flexible bridge type reinforced nylon drag chain, underscoring its authoritative position in cable management solutions.

Manufacturer Comparison & Tailored Solutions

When selecting a drag chain, understanding the differences between manufacturers is paramount. While many suppliers offer cable carriers, the quality of materials, precision of manufacturing, design innovation, and level of customer support can vary significantly. A key differentiator for products like the 68300 mm VMTK flexible bridge type reinforced nylon drag chain lies in its proven track record of durability and performance, backed by rigorous testing and adherence to global industry standards like ISO 9001. Below is a comparative overview highlighting critical aspects when evaluating suppliers for high-performance drag chains:

| Criterion | Generic Manufacturer | Leading Supplier (e.g., Agile Chains) |

|---|---|---|

| Material Quality | Standard Nylon (PA6) | Reinforced Nylon (PA6+GF) - Superior strength, wear, chemical resistance. |

| Manufacturing Precision | Basic injection molding; less consistent. | Advanced, high-precision injection molding; ISO 9001 certified. |

| Design Innovation | Standard designs; limited features. | Optimized bridge-type, noise reduction, quick assembly features (VMTK series). |

| Product Longevity (Cycles) | 1-3 million cycles typical. | 5-10 million cycles verified via testing. |

| Customization Options | Limited standard sizes; few accessories. | Extensive range of bend radii, widths, dividers, mounting brackets, extreme environment solutions. |

| Technical Support | Basic product data sheets. | Dedicated engineering support, application guides, calculation tools. |

| Warranty & Service | Standard 1-year warranty. | Extended warranties, comprehensive after-sales service. |

A leading manufacturer not only provides a superior product but also offers unparalleled customization capabilities. Whether it’s specific internal partitioning for cable segregation, specialized mounting brackets for unique machine architectures, or custom lengths and radii to perfectly fit an application, the ability to tailor solutions is a significant advantage. This ensures optimal performance and simplifies integration, reducing engineering time and potential compatibility issues. Furthermore, for highly specialized or harsh environments, tailored solutions can involve specific additives to the nylon for enhanced chemical resistance, flame retardancy, or anti-static properties. This holistic approach, from material science to bespoke design, ensures that the 68300 mm VMTK flexible bridge type reinforced nylon drag chain meets precise operational demands.

Real-World Impact: Application Case Studies

The practical effectiveness of the 68300 mm VMTK flexible bridge type reinforced nylon drag chain is best illustrated through its successful deployment in challenging industrial scenarios. Consider a large-scale automated gantry system in a high-volume automotive assembly plant. This system's previous cable management solution, a conventional metal chain, suffered from significant noise generation, high wear on cables, and frequent maintenance due to debris accumulation and corrosion, especially around welding stations. These issues led to unplanned downtime, affecting production targets.

Upon implementing the 68300 mm VMTK flexible bridge type reinforced nylon drag chain, several transformative improvements were observed. The reinforced nylon material, with its inherent low-friction properties, dramatically reduced operational noise by over 30%, creating a quieter and safer working environment. Its superior resistance to weld splatter and corrosive fumes, coupled with the enclosed yet accessible bridge-type design, significantly extended the lifespan of critical power and data cables. Maintenance intervals were reduced by 50% due to less wear and easier access for inspection and cleaning, directly translating into increased uptime and substantial cost savings. This real-world application exemplifies how a thoughtfully engineered drag chain can elevate operational efficiency, reduce maintenance overheads, and contribute to a more resilient and productive industrial environment. The project demonstrated a clear ROI within 18 months, primarily from reduced downtime and enhanced cable longevity, validating the investment in a premium cable management solution.

Ensuring Trust and Comprehensive Support

At the heart of any successful B2B partnership is trust, built upon transparency, reliable products, and unwavering support. For critical components like the 68300 mm VMTK flexible bridge type reinforced nylon drag chain, comprehensive customer support and clear commitments are essential.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a custom 68300 mm VMTK drag chain solution?

A: Standard configurations typically ship within 3-5 business days. For highly customized solutions, lead times may range from 2-4 weeks, depending on complexity and order volume. Expedited options are available upon request. -

Q: Is the reinforced nylon suitable for outdoor use or extreme temperatures?

A: Yes, the reinforced nylon (PA6+GF) used in the 68300 mm VMTK flexible bridge type reinforced nylon drag chain offers excellent UV stability and a wide operating temperature range from -40°C to +120°C, making it highly suitable for diverse outdoor and extreme temperature applications. -

Q: What kind of warranty is offered with the product?

A: We offer a comprehensive multi-year warranty on all our drag chains, covering material defects and manufacturing faults. Specific warranty duration details are provided with each quotation, underscoring our confidence in product quality and longevity. -

Q: How do I select the correct bend radius for my application?

A: Selecting the correct bend radius is crucial for cable longevity. Our technical support team provides detailed guidance based on cable type, minimum bend radius of enclosed cables, and application dynamics. We also offer online tools and engineering consultations to assist in precise selection.

Our commitment extends beyond product delivery to include extensive technical support, from initial design consultations to post-installation assistance. This ensures seamless integration and optimal performance throughout the product's lifespan. Our team of experts is readily available to provide in-depth technical specifications, installation guides, and troubleshooting assistance, affirming our role as a trusted partner in industrial automation.

Conclusion: Elevating Industrial Cable Management

The selection of appropriate cable management solutions is a strategic decision that directly impacts the efficiency, safety, and longevity of industrial machinery. The 68300 mm VMTK flexible bridge type reinforced nylon drag chain exemplifies cutting-edge engineering, combining superior material science with intelligent design to deliver a product that stands out in performance and reliability. Its robust construction, ease of maintenance, and adaptability to diverse industrial environments make it an indispensable asset for businesses striving for operational excellence and reduced total cost of ownership.

By understanding its detailed technical parameters, appreciating its precision manufacturing, and recognizing its broad application spectrum, B2B stakeholders can confidently integrate this advanced drag chain into their systems. Investing in such high-quality components is not merely a purchase; it is a commitment to enhanced productivity, minimized downtime, and sustained competitive advantage in the dynamic industrial landscape. The 68300 mm VMTK flexible bridge type reinforced nylon drag chain is more than just a component; it is a critical enabler of uninterrupted, high-performance automation.

Authoritative References

- ISO 9001:2015 Quality Management Systems - Requirements. International Organization for Standardization.

- DIN EN ISO 10328:2016-06 - Flexible technical chains for power and signal transmission - Requirements and test methods. Deutsches Institut für Normung.

- ASTM D638 - Standard Test Method for Tensile Properties of Plastics. ASTM International.

- White Paper: The Impact of Cable Carrier Design on Machine Uptime and Longevity in Automation. Robotics Institute Journal.

- Study on Wear Characteristics of Reinforced Polymers in Dynamic Industrial Applications. Journal of Tribology and Engineering.

- Energy Efficiency in Automated Systems: The Role of Low-Friction Cable Management. Industrial Automation Review.