Durable Plastic Drag Chain Cable Carrier for Efficient Cable Management Solutions

Understanding Plastic Drag Chain Cable Carriers An Essential Component for Modern Machinery

In the ever-evolving landscape of modern machinery and industrial automation, the term plastic drag chain cable carrier has become increasingly significant. These engineering components play a crucial role in the efficient functioning and longevity of various equipment, particularly those involving motion—a feature common in robotic systems, CNC machines, and automated production lines. This article delves into what plastic drag chain cable carriers are, their purpose, and the advantages they bring to industries.

What is a Plastic Drag Chain Cable Carrier?

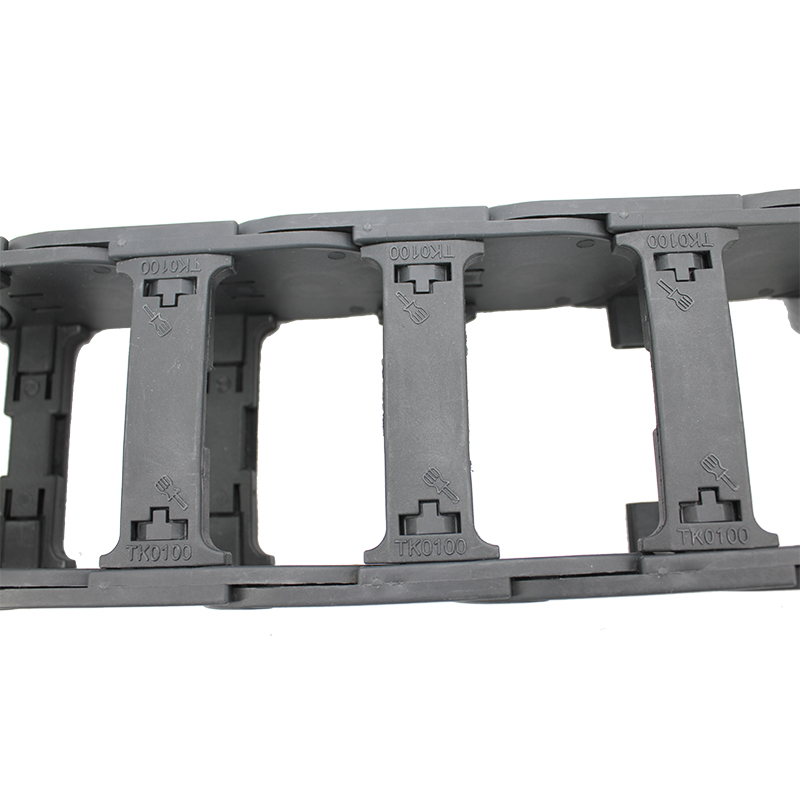

A plastic drag chain cable carrier, often simply referred to as a cable carrier or cable chain, is a system designed to manage flexible cables and hoses in a manner that minimizes wear and allows for movement. The drag chain consists of individual links that connect to form a chain, resembling a flexible tube through which cables and hoses can run. This allows for the efficient routing of power and data lines in machinery that experiences linear or rotational motion.

These carriers are primarily made of high-density polyethylene (HDPE) or other durable plastic materials, which provide several benefits, including lightweight characteristics, resistance to chemicals and abrasion, and the ability to endure extreme temperatures. Their design often includes features such as open or closed profile shapes, which allow for easy insertion and maintenance of cables and hoses, ensuring that they remain organized and protected during operation.

The Purpose of Plastic Drag Chain Cable Carriers

The main function of a plastic drag chain cable carrier is to protect and guide cables and hoses in dynamic applications. They are particularly useful in environments where cables are repeatedly moved back and forth, as is common in robotics, conveyor systems, and other automated systems. By ensuring proper cable management, drag chains help to prevent tangling and mechanical wear, which can lead to failures or costly downtime.

Furthermore, these cable carriers aid in reducing strain on cables. By keeping them contained within the drag chain, the forces applied during movement are distributed more evenly, reducing the likelihood of connection breakage or electrical failures due to wear.

Advantages of Plastic Drag Chain Cable Carriers

plastic drag chain cable carrier

1. Durability The materials used in manufacturing plastic drag chain cable carriers contribute to their longevity. They are resistant to corrosion, chemicals, and extreme temperatures, making them suitable for various industrial environments.

2. Flexibility With customizable lengths and configurations, drag chains can be tailored to meet the specific needs of different applications. This flexibility allows for use in diverse machinery, from simple conveyor systems to complex robotic arms.

3. Ease of Installation and Maintenance Many drag chains are designed for quick assembly and disassembly, facilitating easy installation and maintenance. The open design allows operators to effortlessly add or replace cables and hoses as needed.

4. Space Efficiency By centralizing and organizing cables, drag chains help optimize space within machinery and production areas. This not only improves aesthetics but also enhances safety by reducing the risk of tripping hazards associated with loose cables.

5. Noise Reduction Plastic drag chains can help to dampen vibrations and noise associated with moving cables and hoses. This contributes to a quieter working environment, which is essential in maintaining comfortable conditions for operators.

Conclusion

As industries continue to embrace automation and advanced technologies, the role of plastic drag chain cable carriers becomes ever more vital. They not only aid in the efficient operation of machines but also contribute to the longevity and reliability of the equipment. By protecting cables and hoses from wear and damage, they ensure that operations run smoothly and safely.

In conclusion, plastic drag chain cable carriers are indispensable components in modern machinery, offering a blend of durability, flexibility, and efficiency. For manufacturers and engineers, investing in high-quality drag chains is a strategic decision that pays dividends in the form of enhanced performance and reduced maintenance costs, ultimately contributing to the overall success of industrial operations. Understanding their benefits and applications can lead to better outcomes in today's fast-paced and competitive environments.