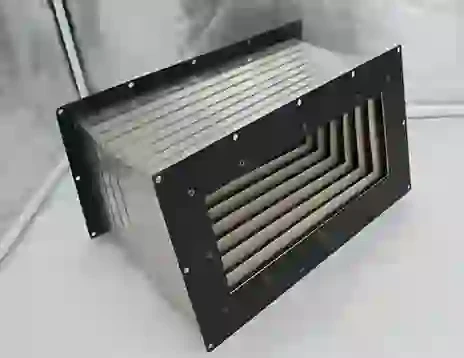

accordion bellows protector

Accordion Bellows Protector A Comprehensive Overview

The accordion bellows protector is an essential component in various industrial and mechanical applications. Often overlooked, this protective device plays a crucial role in safeguarding equipment from the harsh conditions it may encounter. Whether in manufacturing facilities, robotics, or machinery, understanding the benefits and functionalities of accordion bellows protectors is vital for ensuring the longevity and efficiency of equipment.

What is an Accordion Bellows Protector?

An accordion bellows protector is a flexible, accordion-like cover, typically made from materials such as rubber, PVC, or fabric. Its design allows it to expand and contract, making it ideal for protecting moving parts of machines. The bellows function serves as a shield against dust, debris, moisture, and other contaminants that could potentially damage sensitive components.

These protectors are widely used in applications involving linear motion, such as on sliding rails or in CNC machines, where the machinery's elements require protection during operation. Their unique design facilitates movement while providing robust shielding, which is essential for maintaining operational efficiency.

Key Advantages

1. Enhanced Protection The primary purpose of accordion bellows protectors is to safeguard machinery and equipment. They prevent the ingress of foreign particles that can cause wear and tear on mechanical parts, thereby extending the life of the equipment.

2. Flexibility and Range of Motion The accordion design allows for significant flexibility, enabling devices to move freely without hindrance. This characteristic is particularly beneficial in dynamic environments where machinery regularly moves or adjusts.

3. Durable Materials Most accordion bellows protectors are constructed from high-quality, durable materials that can withstand extreme temperatures, chemicals, and physical stress. This durability ensures reliable long-term performance under various environmental conditions.

4. Cost-Effectiveness Investing in accordion bellows protectors can lead to substantial savings over time. By preventing costly repairs and minimizing downtime due to equipment failure, these protectors can yield a significant return on investment.

accordion bellows protector

5. Ease of Installation Many accordion bellows protectors come with user-friendly mounting solutions, making installation straightforward. This ease of installation can lead to lower labor costs and faster implementation in industrial settings.

Applications Across Industries

Accordion bellows protectors find applications across a multitude of industries. In the manufacturing sector, they protect machine components from chips, dust, and coolant exposure, which are prevalent during metalworking processes. In robotics, they shield electrical wires and sensitive sensors from damage, ensuring smooth and reliable operation.

Additionally, these protectors are commonly used in the construction industry to safeguard hydraulic cylinders and other equipment from dust and debris. Their versatility also extends to automotive engineering, where they protect vital components in engines and machinery.

Maintenance and Lifespan

While accordion bellows protectors are known for their durability, regular maintenance is essential to ensure their optimal performance. Users should regularly inspect the bellows for signs of wear, cracks, or damage. Properly maintaining these protectors involves cleaning to remove any built-up dust or debris and ensuring that they are correctly lubricated if necessary.

The lifespan of an accordion bellows protector depends on various factors, including the materials used, the environment in which it operates, and the frequency of maintenance. Typically, with proper care, these protectors can last several years, providing ongoing protection to expensive equipment.

Conclusion

In summary, accordion bellows protectors are invaluable components that provide essential protection for various machinery and equipment across multiple industries. Their ability to shield against dust and debris, combined with their flexible design and durable materials, ensures that they play a critical role in maintaining the efficiency and longevity of machinery. As industries continue to evolve, the importance of such protective devices will only grow, highlighting the need for manufacturers and operators to prioritize equipment safeguarding through the use of accordion bellows protectors.