wood chip screw conveyor

The Benefits and Applications of Wood Chip Screw Conveyors

Wood chip screw conveyors are essential tools in various industries, particularly in biomass processing, pulp and paper production, and woodworking facilities. These conveyors are designed to transport wood chips and other bulk materials efficiently. Their unique construction and operational features make them ideal for handling large volumes of material with minimal effort and maximum efficiency.

What is a Wood Chip Screw Conveyor?

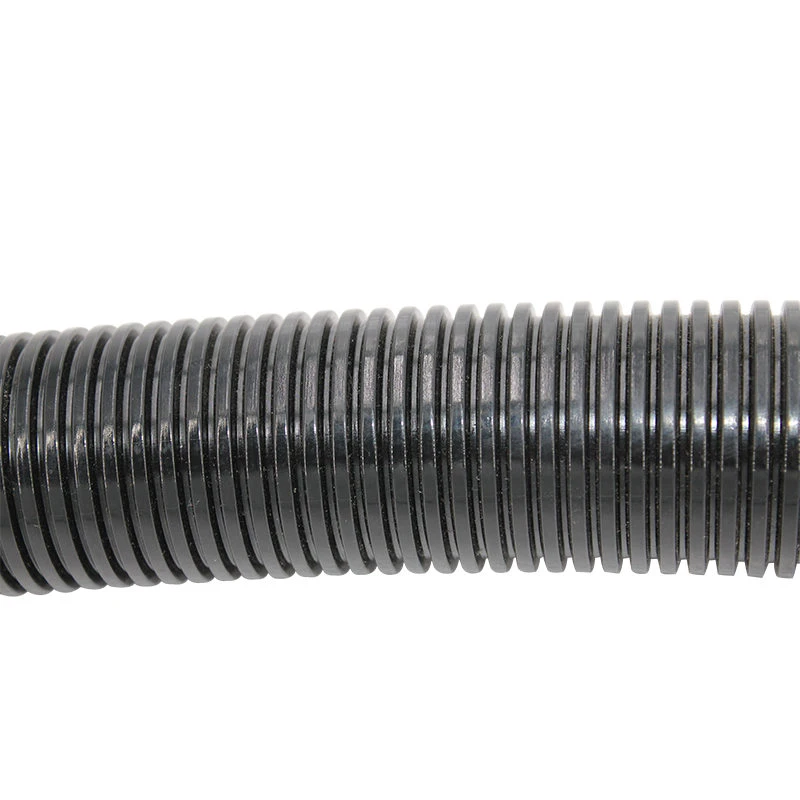

A wood chip screw conveyor is a type of mechanical conveyor that uses a rotating helical screw blade, known as a screw or auger, to move materials along a fixed casing. This design allows for a continuous flow of wood chips from one point to another, which is crucial in operations such as transferring raw materials to processing machinery or stocking finished products for shipping.

These systems can be configured for horizontal, inclined, or vertical transport, making them versatile for different layouts and space constraints in industrial settings. Typically made of robust materials resistant to wear and tear, wood chip screw conveyors are built to withstand harsh working conditions commonly found in wood processing and biomass operations.

Key Advantages

1. Efficient Material Handling Wood chip screw conveyors can handle large volumes of wood chips effectively, reducing the need for manual labor and increasing operational efficiency. Their ability to convey materials in a continuous flow helps to streamline production processes.

2. Space-Saving Design These conveyors can be designed to fit specific space requirements, allowing industries to maximize their floor space while ensuring smooth material movement. Their vertical or inclined configurations can be particularly useful in facilities with limited horizontal space.

3. Low Maintenance Wood chip screw conveyors are generally low-maintenance systems. Their simplified design and fewer moving parts mean less wear and tear, resulting in lower maintenance costs and less downtime, which is critical for operations that require continuous production.

wood chip screw conveyor

4. Customizable Screw conveyors can be tailored to meet the specific needs of a facility. Factors such as screw diameter, pitch, and conveyor length can be adjusted based on the type of material being handled and the operational requirements. This customization ensures optimal performance and efficiency.

5. Safe and Reliable These conveyors are designed with safety in mind. Enclosed systems reduce the risk of spillage and worker exposure to potentially hazardous materials. Furthermore, many screw conveyors come with safety features, like overload protection and emergency stop mechanisms, to minimize accidents.

Applications in Various Industries

1. Biomass Energy In biomass power plants, wood chip screw conveyors are crucial for transporting wood chips from storage to the boiler for energy production. Their ability to handle different moisture content and sizes makes them a reliable choice for biomass fuel handling.

2. Pulp and Paper Industry The pulp and paper industry relies heavily on efficient material handling for wood chips. Screw conveyors transport wood chips to pulping systems, enabling a more streamlined production of paper products.

3. Woodworking Facilities In woodworking factories, these conveyors play a significant role in transporting sawdust, shavings, and wood chips to various processing stations. This organization boosts productivity and helps maintain a clean working environment.

4. Composting Wood chip screw conveyors are also used in composting operations to transport organic waste materials. Their ability to handle a mix of materials ensures that the composting process is efficient and effective.

Conclusion

In summary, wood chip screw conveyors are invaluable assets in industries that manage bulk materials. Their advantageous features, such as efficiency, low maintenance, and customizable designs, make them suitable for various applications, particularly in biomass, pulp and paper, and woodworking sectors. As industries continue to seek ways to enhance efficiency and productivity, the role of screw conveyors in material handling is only expected to grow, solidifying their position as a cornerstone in modern manufacturing and processing operations.