Flexible Corrugated Wire Tubing for Safe and Organized Cable Management Solutions

Understanding Corrugated Wire Tubing An Essential Component for Protection and Organization

In the modern world, the need for efficient organization and protection of wires and cables is more critical than ever. As technology advances and our reliance on electrical systems increases, engineers and product designers have sought innovative solutions to manage these essential components. One such solution is corrugated wire tubing, a versatile material that offers a wide range of applications across various industries.

What is Corrugated Wire Tubing?

Corrugated wire tubing, also known as spiral wire wrap or corrugated conduit, is a flexible protective covering designed to encase and manage bundles of wires and cables. Typically made from materials such as polyethylene, nylon, or PVC, this tubing features a ribbed design that allows for flexibility, durability, and ease of installation. The corrugated structure provides extra resistance to abrasion, impact, and environmental stress, making it an ideal choice for protecting sensitive electrical components.

Applications of Corrugated Wire Tubing

The applications of corrugated wire tubing are vast and span numerous sectors, including automotive, aerospace, telecommunications, and industrial machinery. Here are some specific applications

1. Automotive Industry In vehicles, wires and cables must be well-organized and protected from harsh conditions such as heat, moisture, and physical wear. Corrugated wire tubing is commonly used to enclose wiring harnesses, ensuring that they remain intact during long journeys and under varying environmental conditions.

2. Aerospace The aerospace sector demands high-performance materials that can withstand extreme conditions. Corrugated tubing is utilized to protect critical wiring in aircraft, safeguarding it against temperature fluctuations and mechanical stress.

3. Telecommunications With the increase in data transmission through fiber optics and copper cables, the telecom industry relies heavily on corrugated tubing to manage and protect these cables. The tubing helps prevent tangling and damage, thereby ensuring reliable communication infrastructure.

4. Industrial Machinery Manufacturing equipment often requires extensive wiring to power various components. Corrugated wire tubing keeps these wires organized, preventing interference and reducing maintenance needs. It also protects against potential hazards like chemical spills and extreme temperatures in industrial environments.

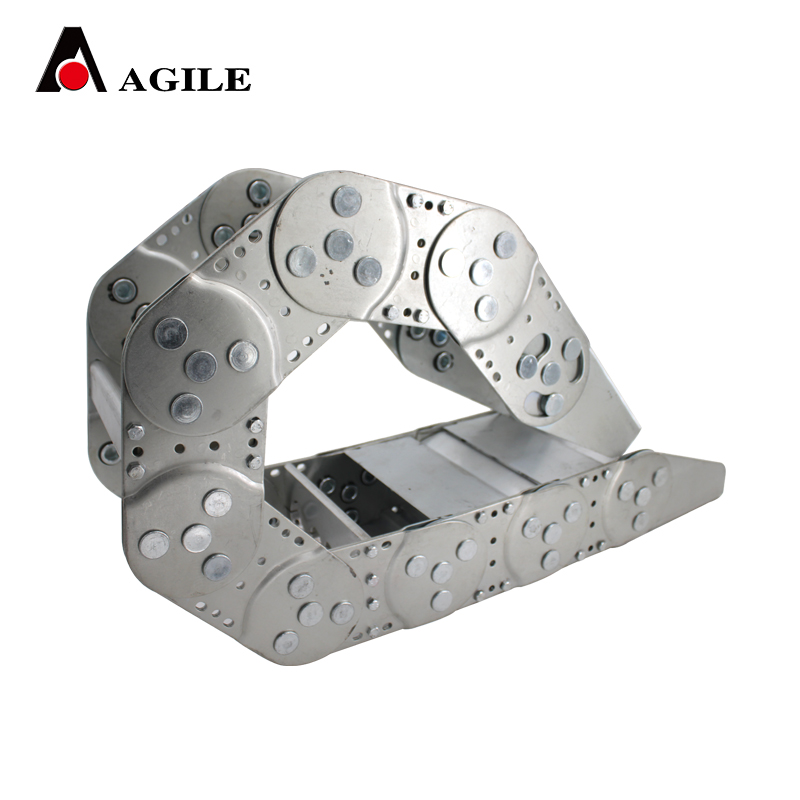

corrugated wire tubing

Benefits of Using Corrugated Wire Tubing

The use of corrugated wire tubing offers numerous advantages, making it a preferred choice among engineers and technicians. Here are some of the key benefits

1. Durability The ribbed design not only provides flexibility but also adds strength against abrasions and impacts. This durability ensures that cables remain protected, extending their lifespan.

2. Flexibility Unlike rigid conduits, corrugated tubing can easily bend and twist, allowing for easy routing of cables in tight spaces or complex assemblies. This flexibility facilitates installation and reduces the need for additional fittings.

3. Weight Savings Corrugated wire tubing is lightweight, which is particularly important in applications where weight reduction can enhance performance, such as in aerospace and automotive industries.

4. Cost-Effectiveness By simplifying installation and reducing potential damage to wires, corrugated wire tubing can lower both material and labor costs. Its capacity to safeguard cables against wear and tear can lead to significant savings in maintenance and replacement.

5. Environmental Resistance Many types of corrugated wire tubing are designed to resist moisture, chemicals, and UV radiation, making them suitable for both indoor and outdoor applications. This resilience ensures reliable performance in a variety of settings.

Conclusion

As industries continue to evolve and the complexity of electrical systems grows, the need for effective wire management solutions becomes increasingly important. Corrugated wire tubing stands out as a practical and efficient option for protecting and organizing wires and cables. Its flexibility, durability, and adaptability to various environments make it suitable for diverse applications, from automotive to telecommunications. By incorporating corrugated wire tubing into their designs, engineers can enhance the reliability and safety of electrical systems, paving the way for continued innovation in technology.