screw type chip conveyor

Understanding Screw Type Chip Conveyors An Essential Component in Modern Manufacturing

In the landscape of modern manufacturing, efficient material handling is pivotal to the success of production processes. Among the various systems designed for this purpose, screw type chip conveyors stand out due to their reliability, simplicity, and effectiveness. This article delves into the fundamental aspects of screw type chip conveyors, their working principles, advantages, and applications.

What is a Screw Type Chip Conveyor?

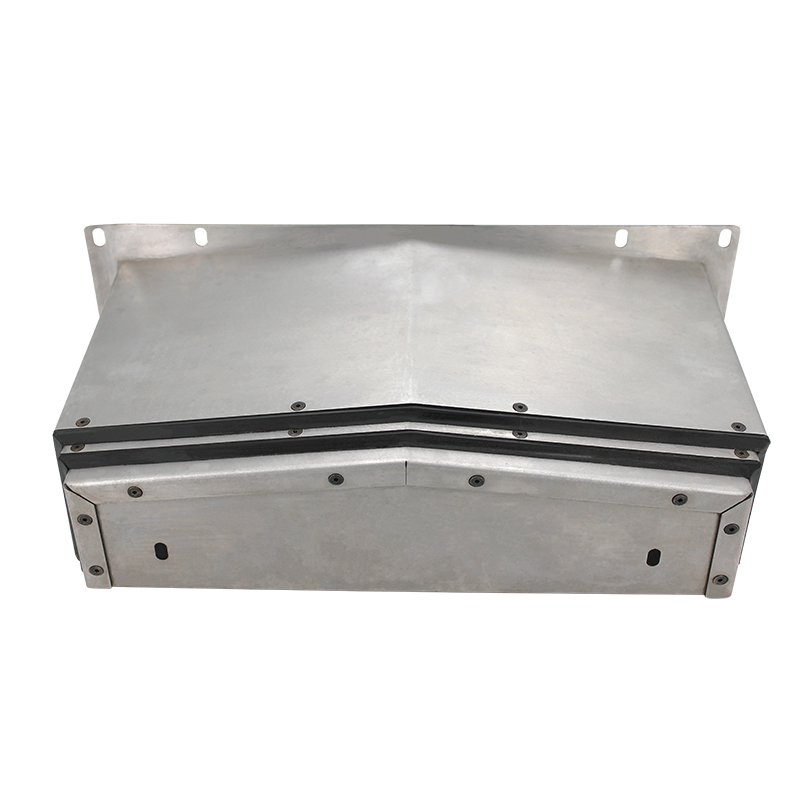

A screw type chip conveyor is a mechanical device that transports metal shavings, chips, and other debris generated during machining operations. This system consists of a helical screw, often housed within a cylindrical or U-shaped conveyor, that rotates to move materials along its length. By utilizing the mechanic principle of the Archimedes screw, these conveyors efficiently guide chips away from machining processes, ensuring a clean and safe working environment.

How Do Screw Type Chip Conveyors Work?

The operation of screw type chip conveyors is relatively straightforward. As machined components are processed, various types of scrap materials, including metal chips and coolant, are produced. The chips enter the conveyor through an infeed chute, where they are caught by the spiral flight of the screw. As the screw rotates, it pushes the chips along the conveyor towards the discharge point. Depending on the design, coolant can be separated from the chips, allowing for recycling or proper disposal.

The configuration of the screw type chip conveyor can vary. Some models include features like vertical lifting capabilities or multiple discharge points, enhancing their versatility in different manufacturing settings. The choice of material for the screw, usually a sturdy metal, helps in resisting wear and tear, ensuring longevity and reduced maintenance costs.

Advantages of Screw Type Chip Conveyors

Screw type chip conveyors offer several advantages that make them a preferred choice in many manufacturing scenarios

screw type chip conveyor

1. Space Efficiency Their compact design allows for easy installation in tight spaces, which is crucial in modern factories where floor space is often at a premium.

2. Low Maintenance With fewer moving parts compared to other conveyance systems, screw type chip conveyors require less maintenance. The helical screw design minimizes wear, prolonging the life of the device.

3. Versatility These conveyors can handle a variety of materials including ferrous and non-ferrous chips, as well as swarf and other by-products of machining, making them suitable for various industries.

4. Customization Options Manufacturers can tailor screw type chip conveyors to meet specific needs, such as length, diameter, and incline angles, ensuring they fit seamlessly into the existing workflow.

5. Cost-Effective Because of their efficiency and long lifespan, screw type chip conveyors are often more cost-effective over time compared to other types of conveyor systems.

Applications of Screw Type Chip Conveyors

Screw type chip conveyors are commonly found in industries such as metalworking, automotive, aerospace, and manufacturing. In these sectors, they are primarily used to collect and transport metal chips generated from machining operations, such as turning, milling, and grinding. By effectively managing waste, these conveyors contribute to improved workflow, reduced downtime, and enhanced safety for workers.

In conclusion, screw type chip conveyors play a crucial role in modern manufacturing by improving the efficiency of material handling processes. Their reliable design, coupled with various advantageous features, makes them an indispensable component in the machining industry. As manufacturing technologies continue to advance, the role of screw type chip conveyors in maintaining clean and efficient production environments will likely remain significant.