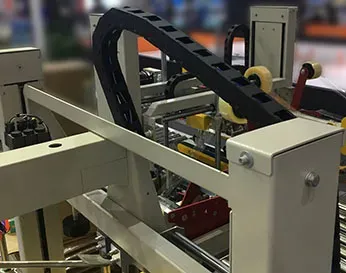

machine way cover bellows

The Importance of Machine Way Cover Bellows in Industrial Equipment

In the realm of industrial machinery, precision and longevity are paramount. Machines are typically subjected to a variety of environmental factors that can lead to wear and tear over time. This is where machine way cover bellows come into play, serving as a crucial protective component in diverse applications, from CNC machines to lathes and milling equipment. In this article, we will explore the function, benefits, and maintenance of machine way cover bellows, shedding light on why they are indispensable in modern industrial environments.

What Are Machine Way Cover Bellows?

Machine way cover bellows are flexible protective coverings designed to shield the linear motion systems of industrial machines. They are typically made from a variety of materials, including fabric, rubber, or metal, and are engineered to move with the machine's components. Their primary function is to protect vulnerable areas, such as guideways and ball screws, from dust, dirt, chips, and other contaminants that can compromise the precision and performance of the machinery.

Key Benefits

1. Protection Against Contaminants The primary benefit of way cover bellows is their ability to safeguard critical machine parts from harmful debris. In manufacturing environments, contaminants can lead to increased friction and wear, which can adversely affect the machine's accuracy and lifespan. By utilizing bellows, manufacturers can significantly reduce the risk of contamination and maintain optimal performance.

2. Enhanced Longevity By protecting vital components, machine way cover bellows contribute to the overall longevity of industrial machinery. Regular exposure to damaging elements can lead to frequent machine breakdowns and costly repairs. Bellows help to mitigate these risks, leading to lower maintenance costs and higher equipment uptime.

3. Improved Safety Safety is a leading priority in industrial operations. Machinery that is not properly protected can pose safety hazards to operators. Way cover bellows minimize the risk of flying debris or other hazards by keeping moving parts concealed and contained, thus enhancing workplace safety.

4. Flexibility and Versatility One of the standout features of bellows is their flexibility. They can accommodate a range of movements while still providing a tight seal against contaminants. This versatility makes them suitable for different types of machinery and applications, from heavy-duty milling equipment to precision CNC machines.

machine way cover bellows

Maintenance of Machine Way Cover Bellows

While machine way cover bellows are designed for durability, regular maintenance is essential to ensuring their effectiveness. Here are a few tips for maintaining these protective coverings

1. Regular Inspections Periodic visual inspections can help identify signs of wear and tear, such as tears or punctures in the bellows. If any damage is detected, it should be addressed promptly to prevent further contamination.

2. Cleaning Keeping the bellows clean is crucial. Dust and debris can accumulate on the surface and may compromise their protective abilities. A gentle cleaning routine with appropriate materials can help maintain their performance.

3. Proper Installation Ensuring that the bellows are installed correctly is vital for their functionality. Misalignment or improper fitting can lead to gaps that allow contaminants to enter. Regular checks can confirm proper installation and tight sealing.

4. Replacement Eventually, wear and fatigue will necessitate the replacement of way cover bellows. It is critical to use high-quality replacements that match the specifications of the original equipment to ensure continued protection.

Conclusion

In conclusion, machine way cover bellows are an essential element in maintaining the efficiency and longevity of industrial machinery. Their ability to protect vital components from contaminants, coupled with their flexibility and versatility, make them a valuable investment in any manufacturing environment. By committing to regular maintenance and timely replacements, operators can ensure that their machines perform at their best, ultimately leading to enhanced productivity and reduced operational costs. As industries continue to evolve, the significance of these protective coverings will only grow, underscoring their crucial role in modern manufacturing processes.