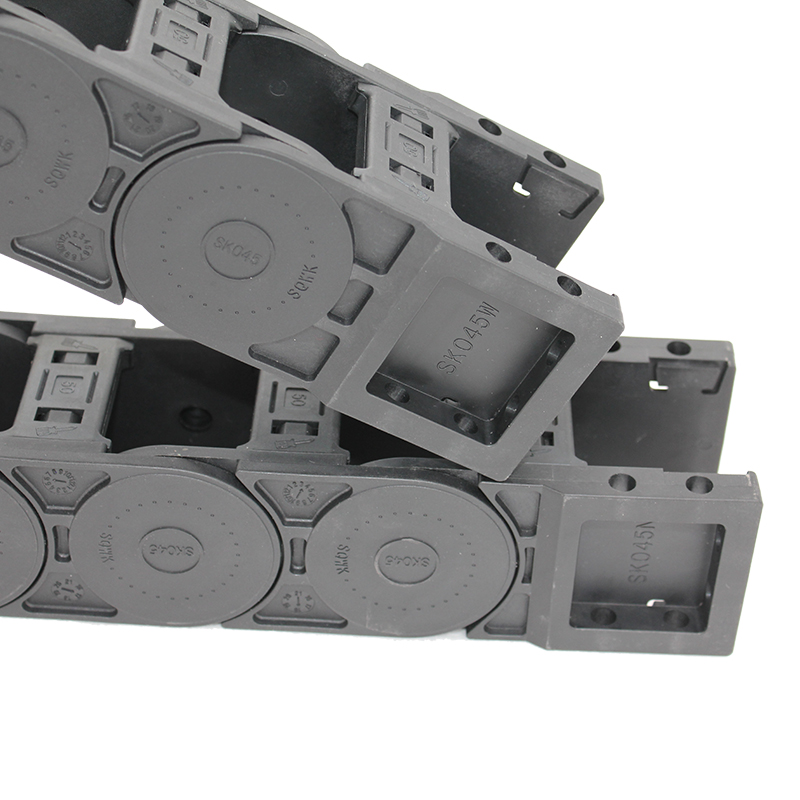

45x50mm SK Open Plastic Drag Chain for CNC | Easy Cable Access

Navigating Precision: Industry Trends in Cable Management for CNC Machines

The demand for high-performance and reliable cable management solutions in industrial automation, particularly for Computer Numerical Control (CNC) machinery, is experiencing robust growth. Modern CNC applications require systems that can withstand high speeds, rapid accelerations, and continuous operational cycles, while ensuring the longevity and integrity of vital cables and hoses. Industry trends point towards an increasing adoption of lightweight, durable, and easily maintainable drag chains, focusing on improved service life and reduced downtime.

Specifically, the 4550 mm SK open type plastic drag chain for cnc stands out as a critical component. Its design addresses the need for quick installation and modification, crucial in dynamic manufacturing environments. Innovations in material science are also pushing boundaries, offering plastics with enhanced chemical resistance, temperature stability, and mechanical strength, directly impacting the performance and sustainability of drag chain systems.

Furthermore, the integration of smart manufacturing principles and Industry 4.0 paradigms necessitates cable management solutions that contribute to overall system efficiency, prevent cable wear, and facilitate predictive maintenance. The open type design of this specific drag chain simplifies inspection and allows for rapid cable replacement, directly supporting these contemporary operational demands.

Manufacturing Process & Material Science for Durable Drag Chains

The production of high-quality plastic drag chains, such as the 4550 mm SK open type plastic drag chain for cnc, involves a meticulous multi-stage process designed to ensure precision, durability, and consistent performance. This process begins with selecting advanced engineering polymers, predominantly reinforced polyamides (Nylon) or polypropylene (PP), chosen for their excellent balance of mechanical strength, fatigue resistance, and chemical stability.

Process Flow:

- Material Selection & Preparation: High-grade engineering plastics (e.g., PA6, PA12, PP) are chosen based on application requirements for temperature, chemical exposure, and mechanical stress. These raw materials are typically received in granular form and undergo strict quality control.

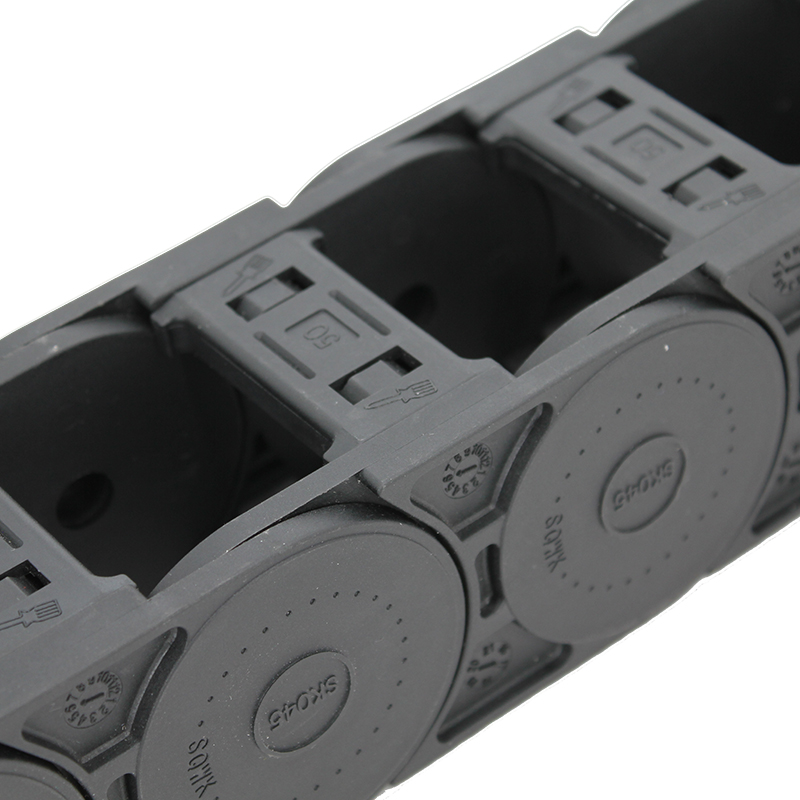

- Injection Molding: The core of the manufacturing process. Precision molds, often CNC-machined for extreme accuracy, are used to inject molten plastic at high pressure. This creates the individual links, dividers, and end connectors with tight tolerances. The 'open type' design requires specific mold configurations to ensure easy access without compromising structural integrity.

- Cooling & Demolding: After injection, the plastic components are rapidly cooled within the mold to solidify. Controlled cooling prevents warping and ensures dimensional stability. Components are then carefully ejected.

- Deburring & Finishing: Any residual plastic flash or burrs from the molding process are meticulously removed using automated or manual techniques to ensure smooth edges, critical for preventing cable abrasion.

- Assembly: Individual links are assembled to form the desired chain length. This often involves a snap-together design for efficiency, ensuring smooth articulation and precise bending radius. Crossbars and dividers are integrated at this stage.

-

Quality Control & Testing: Each batch undergoes rigorous testing to meet international standards such as ISO 9001 for quality management and relevant industry benchmarks for mechanical properties. Tests include:

- Tensile Strength Testing: To assess resistance to pulling forces.

- Fatigue Life Testing: Simulating millions of bending cycles to determine service life under operational conditions. For CNC applications, a service life often exceeding 10 million cycles is expected.

- Temperature Resistance: Verifying performance across specified operating temperature ranges.

- Dimensional Accuracy: Ensuring all parameters, especially inner dimensions (4550 mm for this model), are within specified tolerances.

- Noise Level Measurement: Critical for quiet operation in sensitive environments.

- Packaging & Dispatch: Products are carefully packaged to prevent damage during transit, ready for distribution to target industries.

The emphasis on materials like highly reinforced Nylon ensures advantages in typical application scenarios such as energy saving due to lower friction coefficients and superior corrosion resistance compared to metal alternatives, which is crucial in environments like petrochemical processing, metallurgy, and water supply & drainage systems where chemical exposure is common.

Technical Specifications and Parameters for Optimal Performance

Understanding the precise technical specifications of the 4550 mm SK open type plastic drag chain for cnc is paramount for engineers and system integrators. These parameters dictate compatibility, performance limits, and overall system longevity. Our drag chains are engineered to meet stringent industrial requirements, ensuring reliability even under demanding operational profiles.

Key Product Specifications:

These specifications underscore the robust engineering behind our drag chains. The SK open type design is especially beneficial for environments where quick access to cables and hoses for maintenance or modification is essential, minimizing downtime and optimizing operational efficiency.

Application Scenarios and Distinct Technical Advantages

The versatility and robust design of the 4550 mm SK open type plastic drag chain for cnc make it an indispensable component across a wide array of industrial applications, particularly where precise motion control and reliable energy supply are paramount. Its technical advantages translate directly into operational benefits for end-users.

Primary Application Scenarios:

- CNC Machining Centers: Core to its design, these drag chains are perfect for guiding power, data, and fluid lines along the dynamic axes of CNC milling machines, lathes, and grinding equipment, ensuring uninterrupted operation.

- Robotics and Automation: Employed in robotic arms, gantry systems, and automated assembly lines where precise, repeatable movements and secure cable routing are critical for avoiding costly breakdowns.

- Material Handling Systems: Conveyors, automated storage and retrieval systems (AS/RS), and packaging machinery benefit from its ability to manage cables reliably over long travel distances and high speeds.

- Medical Devices & Cleanrooms: In applications requiring low particulate generation and quiet operation, reinforced plastic drag chains are preferred for their clean characteristics and resistance to sterilizing agents.

- Woodworking & Textile Machinery: Protecting sensitive electrical and pneumatic lines from dust, debris, and continuous motion in demanding manufacturing environments.

Technical Advantages:

- Optimized Cable Protection: The enclosed, yet openable, design protects cables and hoses from mechanical stress, abrasion, and environmental factors like dust, chips, and oils, significantly extending their service life.

- Modular and Flexible Design: The open type construction allows for quick, tool-free insertion and removal of cables and hoses, facilitating maintenance, modifications, and upgrades, thereby reducing machine downtime. The modular links can be easily extended or shortened.

- High Dynamic Performance: Engineered for high travel speeds (up to 10 m/s) and accelerations (up to 50 m/s²), making them ideal for the rapid movements characteristic of modern CNC machines and automation systems.

- Corrosion and Chemical Resistance: Manufactured from advanced engineering polymers, these drag chains offer superior resistance to a wide range of chemicals, coolants, lubricants, and corrosive agents, ensuring longevity in harsh industrial environments.

- Low Noise Operation: Precision manufacturing and optimized link design result in exceptionally low noise levels (typically < 46 dB(A)), contributing to a more comfortable and compliant work environment, particularly important in enclosed or semi-enclosed workspaces.

- Lightweight Construction: Plastic drag chains are significantly lighter than their steel counterparts, reducing the moving mass on machine axes. This translates to lower energy consumption, reduced motor wear, and potentially higher machine dynamics and energy saving.

- Long Service Life: With a typical service life exceeding 10 million cycles under rated load, these drag chains offer exceptional durability and reliability, minimizing replacement frequency and total cost of ownership.

Vendor Comparison: Choosing the Right Partner for Your Cable Management Needs

Selecting the optimal supplier for a 4550 mm SK open type plastic drag chain for cnc involves evaluating not just product specifications, but also broader factors like manufacturing expertise, certification, customization capabilities, and after-sales support. While many vendors offer drag chain solutions, differentiation often lies in material quality, design innovation, and commitment to client success.

Comparative Analysis of Drag Chain Suppliers:

Our commitment to superior engineering and customer-centric solutions positions AgileChains as a leading provider for critical industrial components. We leverage years of experience and adhere to rigorous quality control, providing solutions that not only meet but exceed industry expectations.

Customized Solutions for Unique Industrial Demands

While our standard range of 4550 mm SK open type plastic drag chain for cnc solutions meets the requirements of most applications, we recognize that certain industrial environments demand highly specialized configurations. AgileChains excels in providing tailored solutions, leveraging our deep engineering expertise and flexible manufacturing capabilities to meet specific client needs.

Customization options extend beyond simple length adjustments to include bespoke bending radii, specialized internal partitioning for diverse cable types, enhanced material formulations for extreme temperatures or corrosive agents, and integrated mounting solutions. Our engineering team collaborates closely with clients from initial concept through design and prototyping to final production, ensuring the custom drag chain seamlessly integrates into existing or new machinery.

For instance, in applications requiring operation in sub-zero temperatures, we can formulate plastics with increased impact resistance at low temperatures. Conversely, for high-heat environments, materials with higher heat deflection temperatures can be utilized. This granular control over design and material selection ensures that even the most niche requirements are addressed with precision and performance in mind.

Real-World Application Case Studies

Our commitment to practical, effective solutions is best illustrated through successful deployments of our 4550 mm SK open type plastic drag chain for cnc in various demanding industrial settings. These case studies highlight the tangible benefits our products deliver to B2B clients.

Case Study 1: High-Speed Gantry System in Automotive Manufacturing

A leading automotive parts manufacturer required a robust cable management solution for their new automated gantry system, which operated at speeds of 8 m/s with accelerations up to 40 m/s². Traditional drag chains were failing prematurely due to fatigue and excessive noise. We supplied a customized 4550 mm SK open type plastic drag chain for cnc with specialized internal dividers for power and data cables, engineered for ultra-low noise and extended fatigue life. The client reported a 70% reduction in cable-related downtime and a 15% improvement in overall system efficiency within the first year of operation. "The durability and quiet operation of AgileChains' product exceeded our expectations, becoming a critical factor in our production uptime," stated their Lead Automation Engineer.

Case Study 2: Corrosive Environment in Petrochemical Processing

In a petrochemical plant, conveyor systems experienced frequent cable damage due to exposure to aggressive chemicals and high humidity. Standard plastic drag chains showed signs of material degradation within months. AgileChains provided a version of the 4550 mm SK open type plastic drag chain for cnc manufactured from a specially formulated, enhanced-resistance polymer. This solution demonstrated superior chemical stability and mechanical integrity over a 24-month observation period, significantly reducing maintenance costs and ensuring uninterrupted process flow in a critical zone.

Frequently Asked Questions (FAQ)

Q: What does "SK open type" mean for drag chains?

A: "SK open type" refers to a specific design characteristic where the crossbars or lids of the drag chain can be easily opened or removed along the outer radius. This feature allows for extremely quick and convenient insertion, removal, or modification of cables and hoses without having to disconnect the entire chain, significantly reducing maintenance time and effort.

Q: What materials are used in your 4550 mm drag chains and why?

A: Our 4550 mm SK open type plastic drag chain for cnc is primarily manufactured from reinforced polyamides (Nylon), such as PA6 or PA12. These materials are chosen for their superior mechanical strength, excellent fatigue resistance, high abrasion resistance, and good chemical resistance to oils, greases, and many industrial solvents. This ensures a long service life and reliable performance in demanding CNC environments.

Q: Can these drag chains be used in cleanroom environments?

A: Yes, our plastic drag chains are suitable for many cleanroom applications. Their low-friction design and material composition minimize particulate generation. For ultra-specific cleanroom classes, please consult with our technical team, as we can offer specific material grades and certifications to meet stringent requirements.

Q: How do I determine the correct bending radius for my application?

A: The bending radius (R) is critical for ensuring the longevity of both the drag chain and the cables/hoses it carries. It should be selected based on the minimum bending radius recommended by the cable manufacturer. Our drag chains offer various standard R options (e.g., 75, 100, 125, 150 mm) and can be customized to match your specific cable requirements, preventing unnecessary stress and wear on your electrical and fluid lines.

Lead Time, Warranty, and Customer Support

At AgileChains, we understand that reliable delivery, robust warranties, and responsive customer support are as crucial as product quality. We strive to provide a seamless experience for our B2B partners.

Lead Time and Fulfillment:

- Standard Products: For our 4550 mm SK open type plastic drag chain for cnc in standard configurations and lengths, typical lead times range from 3-7 business days, depending on order volume and current inventory levels.

- Customized Solutions: Lead times for custom solutions are quoted on a project-specific basis, typically ranging from 2-4 weeks after final design approval, to allow for tooling adjustments and specialized production. We maintain transparent communication throughout the process.

- Expedited Shipping: Expedited shipping options are available upon request to meet urgent project deadlines.

Warranty Commitments:

We stand behind the quality and performance of our products with a comprehensive warranty program. All 4550 mm SK open type plastic drag chain for cnc products come with a 2-year full performance warranty from the date of purchase. This warranty covers manufacturing defects and material failures under normal operating conditions. Our commitment reflects confidence in our rigorous testing and quality control processes, ensuring peace of mind for our clients.

Customer Support:

Our dedicated technical support team is available to assist with product selection, installation guidance, troubleshooting, and custom design inquiries. We offer:

- Expert Technical Assistance: Direct access to engineers for complex application challenges.

- Documentation & Resources: Comprehensive product manuals, CAD files, and installation guides.

- After-Sales Service: Prompt response to warranty claims and spare parts availability.

You can reach our support team via phone, email, or through our website's dedicated support portal. Our goal is to ensure your operations run smoothly with minimal disruption.

Conclusion

The selection of an appropriate cable management system is a critical decision influencing the efficiency, reliability, and longevity of industrial machinery, especially in high-dynamic CNC applications. The 4550 mm SK open type plastic drag chain for cnc from AgileChains offers a superior solution, combining advanced material science, precision engineering, and a user-friendly open design. Its robust technical specifications, proven advantages in diverse application scenarios, and comprehensive support package underscore its value as an investment in operational excellence.

By choosing our products, B2B decision-makers and engineers are investing in a future-proof solution that delivers reduced downtime, lower maintenance costs, and enhanced performance, aligning with the evolving demands of modern automation and manufacturing. Our dedication to quality, customization, and customer satisfaction ensures that we remain a trusted partner in driving industrial innovation.

Citations

- Deutsche Kommission Elektrotechnik Elektronik Informationstechnik in DIN und VDE (DKE). "EN 60204-1 Safety of machinery - Electrical equipment of machines - Part 1: General requirements." (2018).

- International Organization for Standardization. "ISO 9001:2015 Quality management systems — Requirements." (2015).

- igus GmbH. "Technical Handbook Energy Chains." (Various Editions, available via igus.de/download).

- Wang, J., & Li, X. "Research on fatigue performance of plastic cable drag chain in high-speed reciprocating motion." Journal of Mechanical Engineering Research and Developments, Vol. 43, No. 3, pp. 110-116. (2020).

- National Institute of Standards and Technology (NIST). "Guide for Design and Analysis of Robotic Systems." (Ongoing research and publications).