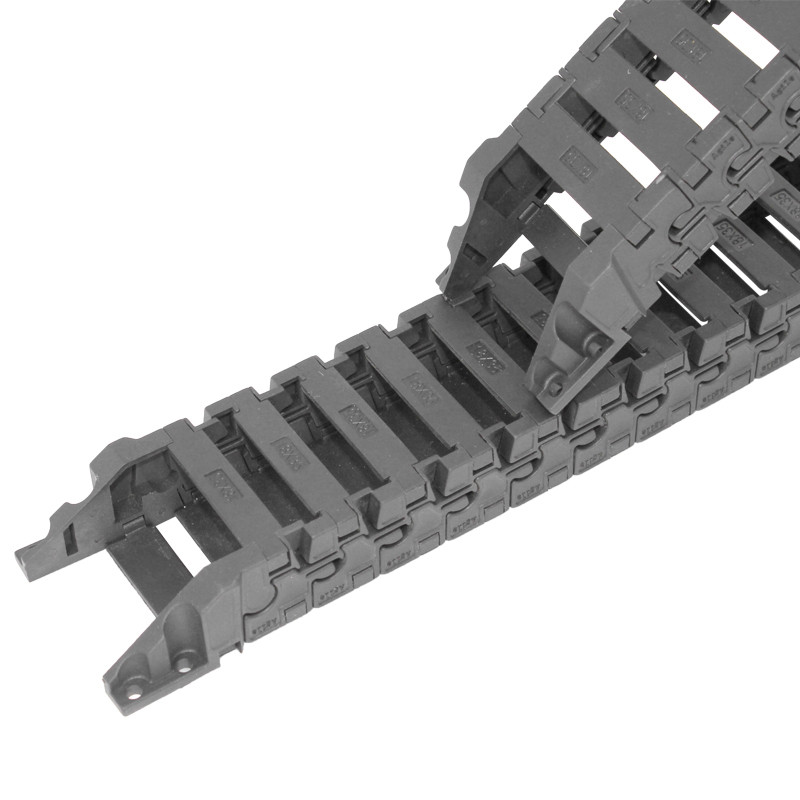

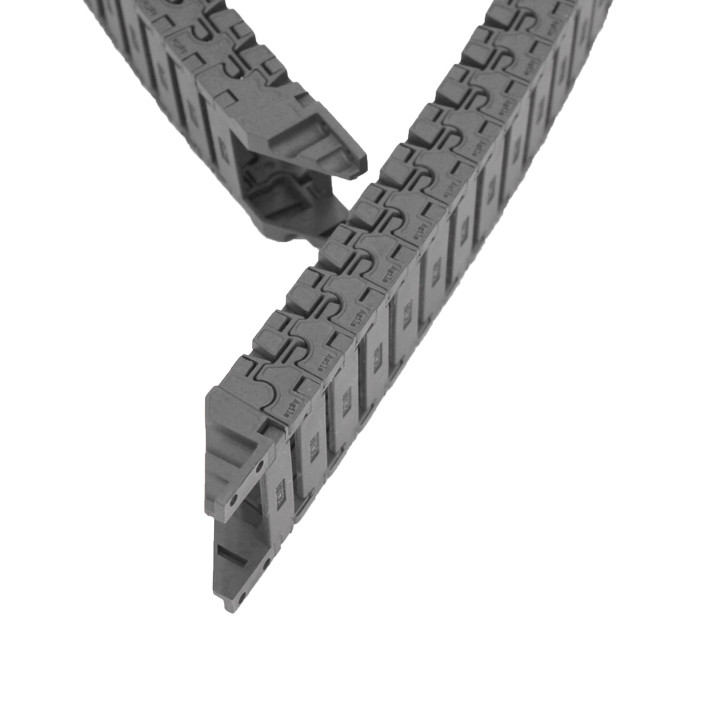

1835 High Speed Low Noise Sabin Reinforced Nylon Muted Drag Chain

Quiet power in a compact frame: 1835 high speed low noise sabin reinforced nylon muted drag chain

Factories are getting faster—and a lot quieter. That’s not a buzzword thing; it’s a competitive advantage. In robotics cells, cobots, and high-speed packaging lines, cable management either supports uptime or becomes the squeaky weak link. This piece looks at how a compact 18×35 mm chain built from reinforced PA6/PA66 is being tuned for higher velocities, lower dB(A), and fewer surprises on the shop floor.

What’s new in drag chain trends

Three things keep coming up in buyer calls: stable acoustics at speed, clean cable separation, and predictable service life. Actually, a fourth—no recycled resin. Many customers say virgin PA66 blends simply hold geometry better over millions of cycles, especially when the machine warms up after shift change.

Core specifications (18×35 mm inner size)

| Parameter | Spec (≈ / typical) |

|---|---|

| Material | Reinforced Nylon PA6/PA66 (virgin resin; no recycled content) |

| Inner cavity (H×W) | 18 × 35 mm |

| Recommended speed | up to ≈ 5 m/s (real-world use may vary) |

| Noise level | ≈ 58–62 dB(A) at 1 m, per ISO 3746 method |

| Bending radius | R ≈ 40–55 mm options |

| Operating temperature | -25 °C to +100 °C continuous |

| Flammability | UL 94 HB standard (V-2 available upon request) |

Manufacturing and QA workflow

Materials: virgin PA6/PA66 compounded with glass/mineral reinforcement for stiffness-to-weight. Methods: precision injection molding, mold temperature control, gate optimization to reduce warpage (yes, the boring stuff that prevents noisy slap at speed). Post-mold conditioning for dimensional stability. Testing: tensile per ISO 527, flexural per ISO 178, abrasion screening (DIN-style methods), and acoustic checks to ISO 3746 in a semi-anechoic environment. Typical service life: >10 million cycles at rated radius and balanced fill factor; to be honest, cabling practice still decides half the story.

Where it fits

Robotics wrists and 7th-axis shuttles, compact CNC gantries, SMT pick-and-place, 3D printers with enclosed bays, and high-throughput packaging lines where operators stand nearby. Many integrators pair the 1835 high speed low noise sabin reinforced nylon muted drag chain with low-capacitance robot cables and separators to keep everything calm at acceleration.

Real-world example

A North China packaging OEM swapped legacy open-link carriers for the 1835 high speed low noise sabin reinforced nylon muted drag chain on a medicine cartoner. Result: about ≈3 dB(A) reduction at operator ear height, fewer cable scuffs, and 12% faster cycle rate after retuning accel profiles. Not earth-shattering—but tangible on a 24/6 line.

Vendor comparison (quick take)

| Criteria | AgileChains 18×35 | Generic A | Generic B |

|---|---|---|---|

| Resin purity | Virgin PA6/PA66 | Blend; may include recycled | Unknown |

| Noise at 5 m/s | ≈58–62 dB(A) | ≈63–67 dB(A) | ≈>65 dB(A) |

| Mold options | Wide; custom tooling offered | Limited | Limited |

| Lead time | ≈ 7–15 days | ≈ 2–4 weeks | Varies |

| Certifications | RoHS, REACH; UL options | RoHS | Not stated |

Customization and support

- Special radii, crossbars, and separators for mixed media

- Flame-retardant grades (UL 94 V-2) on request

- On-site cabling guidance (fill factor, clamp strategy)

- Batch acoustic reports and lifecycle test summaries

Advantages that matter: low resonance links, smooth hinge geometry, easy snap-open maintenance, and—this is underrated—consistent mould accuracy that keeps cable jackets happy after a long week.

Origin: 100 meters east of the junction between 307 national auxiliary road and Tianshan street, high-tech zone, Shijiazhuang.