Winning the War Against Contamination with Square Bellow Covers

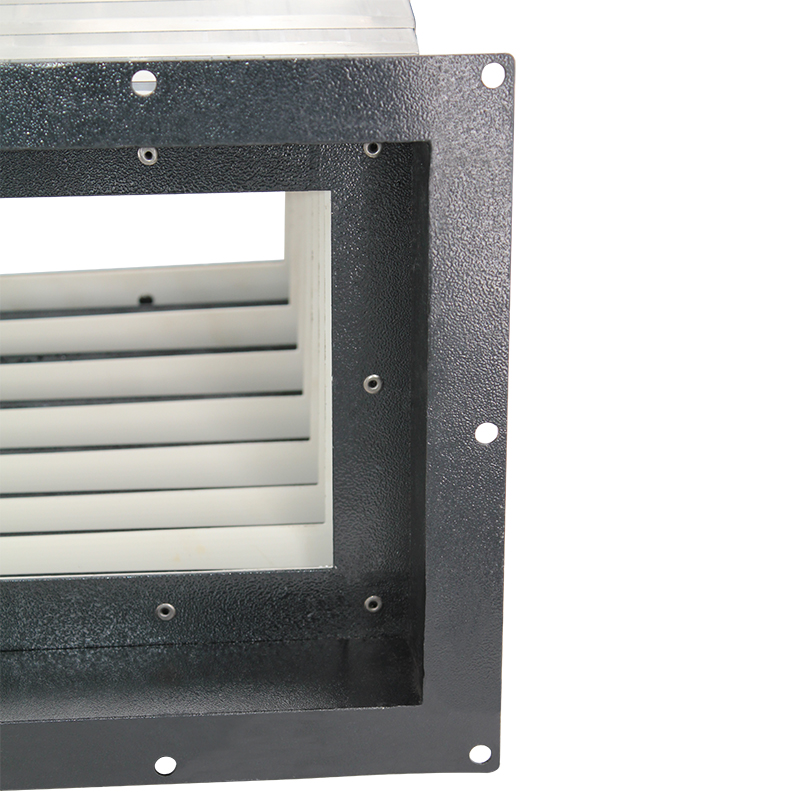

In the relentless environment of modern industry, protecting precision components like linear guides, ball screws, and sensitive electronics from abrasive particles, corrosive liquids, and damaging debris is paramount. Contamination exclusion isn't just a feature; it's the core mission of square bellow cover and telescopic ball screw covers. Failure means accelerated wear, costly downtime, and premature equipment failure. For wholesalers supplying machinery, automation lines, and heavy industrial equipment, understanding the sophisticated strategies employed in high-performance metal bellow cover systems is essential. It translates directly into supplying reliable, long-lasting protection solutions that build trust with bulk buyers and minimize warranty claims. Effective exclusion hinges on a multi-layered approach combining robust materials, intelligent sealing mechanisms, and precision engineering. Shijiazhuang Agile company, established in 2008, brings over 13 years of dedicated expertise to this challenge. Operating from a 6500 sqm factory in Hebei province with a workforce of 100, Agile prioritizes "Quality first" in manufacturing square bellow cover, and telescopic ball screw covers. This commitment ensures rigorous quality control in every stage of producing cable and rail protection solutions for demanding reciprocating motion applications, delivering dependable contamination defense at competitive wholesale prices for industrial partners worldwide.

The Contamination Battlefield: Threats Faced by Square Bellow Covers -h2

Square bellow cover and telescopic ball screw covers(https://www.agilechains.com/steel-metal-square-telescopic-accordion-cylinder-dust-bellow-cover.html) operate on the front lines, constantly exposed to a barrage of harmful elements. Understanding these threats is the first step in designing effective contamination exclusion strategies for metal bellow cover systems:

- Abrasive Solids:Metal chips, grinding dust, sand, concrete particles, and general workshop grit. These act like sandpaper on precision surfaces like ball screws and guide rails within the telescopic ball screw covers.

- Corrosive Liquids:Coolants, cutting oils, lubricants, solvents, water, and chemical spills. These can cause rust, degrade lubricants, and attract more abrasive particles within the square bellow cover.

- Sticky Sludge & Pastes:A dangerous combination of fine particles mixed with coolant or oil, forming a paste that can pack into crevices, impede movement, and accelerate wear, challenging even robust metal bellow cover seals.

Sealing Arsenal: Core Mechanisms for Exclusion in Metal Bellow Covers -h2

The primary defense layer within metal bellow cover systems, including square bellow cover profiles and telescopic ball screw covers, comprises specialized sealing technologies, each suited to specific threats:

- Felt Seals:Compressed felt strips, sometimes lubricant-impregnated, provide a softer barrier. They offer good exclusion of coarse dust and chips and can absorb light moisture. Crucial for: General industrial environments, areas with moderate dry debris. Limitation: Can become saturated with fine particles or liquids, losing effectiveness and potentially holding corrosive agents against the metal bellow cover surface.

- Labyrinth Seals:A non-contact strategy relying on complex, tortuous paths formed by precisely engineered ridges and grooves on the mating surfaces of the telescoping stages. Contaminants lose momentum changing direction repeatedly and fall away. Crucial for:Very dusty environments, applications requiring minimal friction, or protecting sensitive telescopic ball screw covers in settings. Limitation: Less absolute protection against liquids or sticky sludge; relies heavily on manufacturing precision.

- Brush Seals:Composed of dense, fine bristles (stainless steel or synthetic fibers) in a carrier. Bristles conform closely to the moving surface, blocking fine dust while allowing some fluid drainage. Crucial for:Environments with mixed fine debris and light moisture, applications needing low friction and resilience (common in square bellow cover for lighter automation). Limitation: Not suitable for heavy, wet chips alone.

- Hybrid Sealing Systems:The most effective contamination exclusionoften combines mechanisms. Example: An outer scraper seal on a telescopic ball screw cover removes heavy chips/coolant, followed by an inner felt or brush seal to trap finer dust and residual moisture. This layered approach maximizes protection within the metal bellow cover.

Maintaining the Barrier: Ensuring Square Bellow Cover Long-Term Exclusion Performance -h2

Even the best-designed contamination exclusion system in a square bellow cover, or telescopic ball screw covers requires proactive maintenance to sustain peak performance throughout its service life, a key consideration for wholesalers ensuring customer satisfaction:

- Regular Visual Inspections:Schedule checks for visible seal damage (cracks, tears, deformation), excessive wear, packed debris within seal grooves or convolutions, and crucially, signs of contamination inside the protected area. Listen for unusual scraping or grinding noises.

- Systematic Cleaning Protocols:Implement regular cleaning of the exterior cover surfaces and accessible seal areas. Remove accumulated chips, swarf, sludge, and coolant residue that can impede seal function, cause abrasion, or hold corrosive agents. Use cleaning agents compatible with the metal bellow cover material and seals.

- Proactive Seal Replacement:Recognize seals as consumable components. Establish replacement intervals based on operating environment severity and inspection findings. Procure high-quality, compatible replacement seals. Wholesalers add significant value by stocking genuine seal kits for popular square bellow cover and telescopic ball screw covers models.

- Impact of Neglect:Failure to maintain seals directly compromises contamination exclusion. Ingress of debris accelerates wear on both the protected machinery and the internal surfaces of the metal bellow cover itself, leading to premature cover failure and significantly higher total costs for the end-user. Consistent maintenance maximizes the ROI for wholesale clients.

Frequently Asked Questions About Telescopic Ball Screw Covers -h2

What's the best sealing square bellow cover type for a machining center with heavy wet chips? -h3

For this harsh environment, a scraper seal is typically the primary defense on telescopic ball screw covers or square bellow cover units. Often combined with an inner felt or labyrinth seal for finer particles. The scraper physically removes the bulk of the heavy, wet chips during retraction.

Can a square bellow cover be as effective as a telescopic one at keeping out fine dust? -h3

Yes, absolutely. Square bellow cover designs often incorporate deep convolutions that create effective labyrinth paths, combined with high-quality brush or felt seals. The key is the specific design and seal selection for the dust type and concentration. Their rigid structure can sometimes offer advantages in maintaining seal alignment.

How do I know if the seals in my telescopic ball screw covers are failing? -h3

Clear signs include visible metal chips, dust, or coolant residue inside the protected area around the ball screw or guide rails, excessive debris packed around the seal lips, increased resistance when the cover telescopes, unusual noises (scraping, grinding), or visible physical damage to the seals themselves.

Is stainless steel always necessary for good metal bellow cover contamination exclusion? -h3

While stainless steel is highly recommended for its corrosion resistance, durability, and smooth surface finish aiding debris shedding, other metal bellow cover materials like galvanized steel can be used in less corrosive, dry, high-impact environments. However, stainless steel generally offers superior long-term contamination exclusion reliability and lifespan.

Do telescopic ball screw covers need special consideration for coolant exclusion? -h3

Yes. Coolant presents a dual challenge: liquid ingress and the formation of abrasive sludge. Telescopic ball screw covers benefit from scraper seals to remove bulk coolant, potentially combined with felt to absorb residue. Integrated drainage channels or weep holes in the mounting flange or outer stage are crucial to allow coolant to escape outwards before it reaches critical seals or the ball screw. Ensuring the cover mounts slightly angled downward can also aid drainage.

Shijiazhuang Agile understands that effective contamination exclusion is the cornerstone of reliable machine protection. Our expertise in engineering and manufacturing high-performance metal bellow cover and telescopic ball screw covers with optimized sealing strategies ensures your wholesale customers receive durable solutions that maximize equipment uptime and lifespan. Partner with us for bulk supplies built on years of quality commitment.