Durable Organ Bellow Cover | Custom Fit Protection for Machines

Introduction to Advanced Protective Bellows in Industrial Applications

In the rapidly evolving landscape of industrial automation and precision manufacturing, the integrity and longevity of critical machinery components are paramount. Exposure to harsh operational environments—including abrasive swarf, aggressive coolants, fine dust, and mechanical impact—can significantly compromise equipment performance, leading to costly downtime and reduced service life. This necessitates robust protective solutions capable of withstanding these challenges.

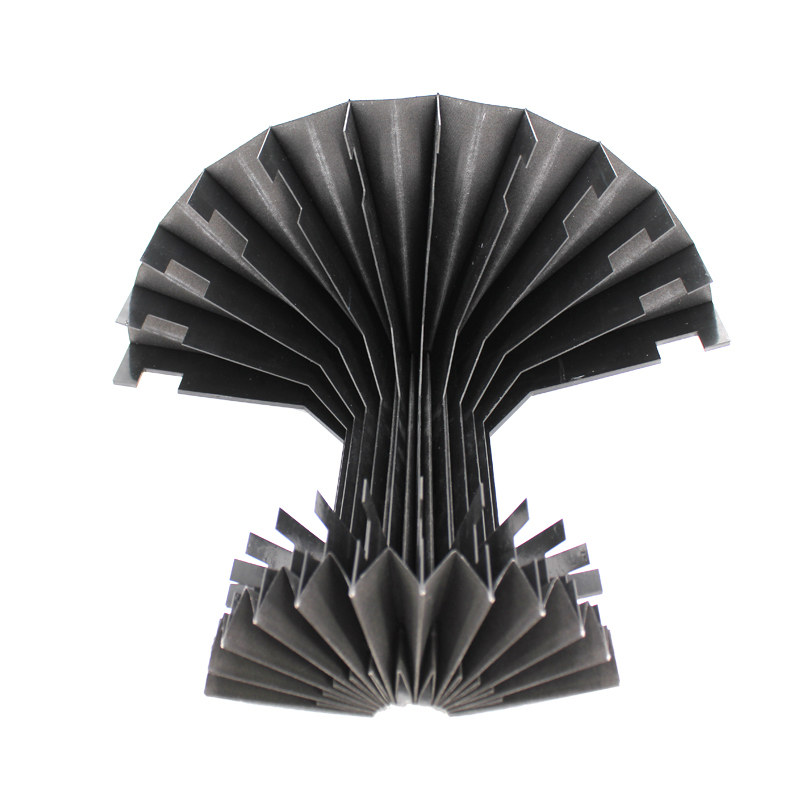

Among the most effective and versatile solutions for safeguarding linear motion systems, guide rails, and other sensitive mechanical parts is the organ bellow cover. These dynamic protective shields, often constructed from advanced materials like nylon protective cloth, are engineered to provide a hermetic seal against contaminants while accommodating extensive machine travel and maintaining flexible articulation. Their accordion-like structure, optimized for both compression and extension, ensures continuous protection without impeding operational movements. This article delves into the critical aspects of these protective components, offering a comprehensive guide for B2B decision-makers and technical engineers.

Industry Trends and Market Dynamics in Machine Protection

The global industrial automation market continues its upward trajectory, driven by increasing demands for precision, speed, and efficiency. This growth directly fuels the demand for high-performance machine protection solutions. Key trends influencing the market for protective covers include:

- Miniaturization and Compact Designs: Modern machinery often requires protective solutions that are space-efficient yet highly effective, pushing innovations in material and pleat design for organ bellow cover systems.

- Harsh Environment Resilience: Industries such as metalworking, woodworking, and petrochemicals demand materials with superior resistance to chemicals, high temperatures, UV radiation, and mechanical abrasion.

- Increased Speeds and Accelerations: As machine axes operate at higher velocities, protective covers must exhibit excellent dynamic properties, low friction, and minimal noise generation.

- Sustainability and Recyclability: A growing focus on environmental responsibility drives the development of eco-friendlier materials and manufacturing processes.

- IoT Integration and Predictive Maintenance: Future trends may involve integrating sensors into protective covers to monitor their condition and predict maintenance needs, further enhancing machine uptime.

According to recent industry analyses, the market for machine protective covers, including bellows and guide way wipers, is projected to grow at a Compound Annual Growth Rate (CAGR) of over 5% from 2023 to 2030, reflecting the increasing investment in advanced manufacturing and the critical role these components play in safeguarding capital equipment.

Figure 1: Typical installation of an organ bellow cover protecting linear guides.

Technical Specifications and Design Principles

The efficacy of a protective organ bellow cover lies in its precise technical specifications and sophisticated design principles. These covers are engineered to provide maximum protection while minimizing interference with machine operation.

Key Design Considerations:

- Material Composition: For guide rail protection, nylon protective cloth is a common choice, offering excellent tensile strength, abrasion resistance, and flexibility. Variants may include PVC coating for enhanced chemical and oil resistance, or special treatments for UV and hydrolysis resistance.

- Pleat Geometry: The size and shape of the pleats are crucial for determining the cover's compression ratio, extension length, and resistance to sagging. Optimal pleat design ensures smooth operation and extended fatigue life.

- Internal Supports: Depending on size and application, internal PVC stiffeners or steel inserts may be used to maintain pleat geometry, prevent collapse, and ensure quiet operation at high speeds.

- Mounting Options: Flanges, velcro, or integrated frames allow for versatile attachment to machine beds and moving parts, ensuring a secure and contaminant-proof installation.

Product Specification Table: Nylon Protective Cloth Guide Rail Organ Bellow Cover Shield

| Parameter | Specification | Units/Details |

|---|---|---|

| Material | Nylon Fabric (PA) with PVC Coating | High-strength, oil/water repellent |

| Operating Temperature Range | -30 to +100 | °C |

| Tensile Strength | >1500 | N/5cm (ISO 13934-1) |

| Flex Life (Cycles) | >1,000,000 | Under typical operating conditions |

| Standard Color | Black, Grey, Blue | Custom colors available |

| Protection Class | IP65 (Dust & Splash Proof) | IEC 60529 Compliant |

| Travel Speed | Up to 120 | m/min (Application dependent) |

| Coefficient of Friction | Low, optimized for smooth movement | Reduces wear on guides |

Figure 2: Close-up of material and pleat construction of a guide rail protective cover.

Manufacturing Process: Ensuring Precision and Durability

The production of a high-quality organ bellow cover involves a series of carefully controlled manufacturing steps, each designed to ensure material integrity, dimensional accuracy, and optimal performance. Manufacturers adhere to stringent quality control standards, such as ISO 9001, throughout the entire process.

Process Flow of an Organ Bellow Cover:

High-grade industrial nylon fabric, often pre-treated for specific resistances (e.g., oil, water, heat), is inspected for defects and prepared for cutting. Compliance with material standards like ASTM D412 for tensile strength and ASTM D2240 for Shore hardness is ensured.

Using advanced CNC laser or ultrasonic cutting machines, the fabric is precisely cut into individual pleat segments. This method ensures clean edges, minimal fraying, and exact dimensions critical for consistent pleat geometry.

The cut segments are then formed into the characteristic accordion pleats. For nylon protective cloth, this often involves high-frequency thermal welding or advanced industrial stitching to create strong, durable seams that resist material fatigue and environmental ingress. This step is crucial for achieving the desired compression ratio and dynamic stability.

For covers requiring enhanced rigidity or larger unsupported spans, internal PVC stiffeners or metallic frames are integrated within the pleats. This ensures structural integrity and prevents sagging, particularly in horizontal applications. Testing against ANSI B11.19 standards for machine guarding is often performed here.

Custom-fabricated end plates or mounting flanges, typically made from PVC, aluminum, or steel, are securely attached to the bellow structure using welding, riveting, or strong adhesives. These provide the interface for mounting the cover to the machine.

Each finished product undergoes rigorous quality checks, including dimensional verification, material integrity tests, and functional testing to ensure smooth operation, adequate compression, and extension. Service life predictions are often based on accelerated fatigue testing, targeting several million cycles. Products are often checked against ISO 12100 for machine safety principles.

Once approved, the bellow covers are carefully packaged to prevent damage during transit and dispatched to clients worldwide.

Figure 3: Production line emphasizing quality control during the manufacturing process.

Application Scenarios and Target Industries

The versatility and protective capabilities of the organ bellow cover make it an indispensable component across a wide array of industrial sectors. Its primary function is to shield critical linear motion components, such as guide rails, ball screws, and hydraulic cylinders, from environmental aggressors, thereby preserving precision and extending operational life.

Key Application Scenarios:

- CNC Machining Centers: Protecting linear guide ways and ball screws from metal chips (swarf), cutting fluids, and abrasive dust generated during milling, turning, and grinding operations. This enhances accuracy and reduces maintenance significantly.

- Laser Cutting and Welding Machines: Shielding sensitive optical path components and linear axes from smoke, particulate matter, and spatters, ensuring consistent beam quality and system precision.

- Robotics and Automation: Covering articulated joints and linear actuators in pick-and-place robots, automated assembly lines, and material handling systems, protecting against dust, debris, and potential impact.

- Woodworking Machinery: Preventing the ingress of fine wood dust and chips, which can severely abrade guide rails and compromise the smooth operation of saws, routers, and CNC wood carving machines.

- Medical and Pharmaceutical Equipment: Ensuring sterile or clean room environments by preventing contamination of sensitive instruments and linear stages in diagnostic equipment, laboratory automation, and packaging machinery.

- Water Supply & Drainage / Petrochemical: Utilizing specialized material variants (e.g., highly chemical-resistant coatings) to protect hydraulic and pneumatic cylinders in valves and pumping stations from corrosive fluids and harsh outdoor conditions.

- Heavy Industry (Metallurgy, Mining): Protecting guide systems in heavy presses, casting machines, and material conveyors from extreme temperatures, abrasive particles, and impact.

Figure 4: Organ bellow covers in a high-precision CNC machining environment.

Technical Advantages and Performance Metrics

The strategic deployment of a quality organ bellow cover offers significant technical advantages that translate directly into operational benefits and cost savings for industrial enterprises.

- Enhanced Machine Lifespan: By effectively preventing particulate ingress, coolant splash, and chemical exposure, bellow covers dramatically reduce wear and corrosion on precision components, extending the operational life of expensive machinery.

- Reduced Maintenance and Downtime: Protecting critical parts minimizes the need for frequent cleaning, lubrication, and replacement of damaged components. This leads to substantial reductions in maintenance costs and unscheduled downtime, improving overall equipment effectiveness (OEE).

- Improved Operational Accuracy: Clean and protected linear guides and ball screws maintain their original precision over a longer period, ensuring consistent product quality and repeatable performance.

- Safety Compliance: Bellow covers also act as a physical barrier, protecting operators from moving machine parts, pinch points, and expelled debris, contributing to a safer working environment and compliance with safety standards.

- Energy Efficiency: By keeping linear motion systems free of contaminants, friction is minimized, leading to smoother operation and potentially reduced energy consumption for axis movement.

- Customization for Specific Needs: The ability to tailor materials, dimensions, and mounting options ensures optimal fit and performance for virtually any machine, no matter the specific environmental or operational demands.

These advantages underscore the value proposition of investing in high-quality protective covers, transforming them from simple accessories into critical components for modern industrial operations.

Vendor Comparison and Selection Criteria

Selecting the right vendor for an organ bellow cover is as crucial as the product's technical specifications. While numerous manufacturers offer protective solutions, key differentiators impact performance, longevity, and overall value. Considerations for vendor comparison include:

- Material Expertise: Does the vendor offer a range of specialized materials (e.g., hydrolysis-resistant nylon, fire-retardant PVC, high-temperature-resistant fabrics) tailored to specific harsh environments?

- Customization Capabilities: Can the vendor provide bespoke solutions for unique machine geometries, travel distances, and mounting interfaces?

- Quality Certifications: Adherence to international standards like ISO 9001 (Quality Management) and environmental certifications (RoHS, REACH) is indicative of reliable manufacturing processes.

- Engineering Support: Availability of experienced application engineers to assist with design, selection, and troubleshooting.

- Lead Time and Logistics: Efficient production and global distribution capabilities ensure timely delivery, particularly for urgent requirements.

- After-Sales Service and Warranty: Comprehensive warranty policies and responsive customer support are vital for long-term satisfaction.

Comparison: Different Types of Guide Rail Protection Bellows

| Feature | Fabric Bellow (Nylon/PVC) | Steel Telescopic Cover | Molded Rubber Bellow |

|---|---|---|---|

| Protection Level | Good (Dust, Coolant, Swarf) | Excellent (Heavy Impact, Hot Chips) | Moderate (Dust, Light Splash) |

| Flexibility/Compression Ratio | High (Excellent for long travels) | Low (Limited) | Medium (Good for short travels) |

| Travel Speed Capability | High (Up to 120 m/min) | Moderate (Up to 60 m/min) | Low to Moderate |

| Cost | Moderate | High | Low to Moderate |

| Space Requirement (Compressed) | Minimal | Significant | Moderate |

| Typical Application | CNC, Laser, Automation | Heavy Machining, Hot Chips | General Industrial, Robotics |

Customized Solutions and Engineering Support

Off-the-shelf solutions often fall short in meeting the precise requirements of highly specialized industrial machinery. Recognizing this, leading manufacturers offer extensive customization capabilities for their protective organ bellow cover products. These bespoke solutions are designed to integrate seamlessly with existing equipment, optimizing protection and operational efficiency.

Customization Options Include:

- Exact Dimensions: Tailored length, width, height, and stroke to match specific machine travel paths and mounting constraints.

- Special Materials & Coatings: Selection from a wide range of fabrics with enhanced properties (e.g., anti-static, flame-retardant, food-grade, extreme temperature resistance) to suit unique environmental demands.

- Integrated Features: Options such as ventilation holes, inspection zippers, guiding rollers for vertical applications, or specialized mounting flanges for quick installation.

- Pleat Design Optimization: Customized pleat height and depth to achieve specific compression ratios or accommodate internal components.

Beyond product modification, comprehensive engineering support is a hallmark of authoritative vendors. This includes initial consultations, CAD design assistance, rapid prototyping, and on-site technical support during installation. Such partnership ensures that the protective solution not only fits mechanically but also performs optimally under specific operational loads and environmental stresses.

Application Case Studies and Customer Successes

Real-world applications demonstrate the tangible benefits of integrating high-quality protective bellows into industrial machinery. These case studies highlight how specialized solutions address specific challenges, leading to significant improvements in operational efficiency and cost reduction.

Case Study 1: High-Speed CNC Machining Center

A leading automotive parts manufacturer faced persistent issues with premature wear on the linear guide rails of their high-speed CNC machining centers. Fine metallic swarf and aggressive cutting coolants were infiltrating the guides, causing increased friction, reduced precision, and requiring bi-monthly maintenance. The existing protection was inadequate for the high-velocity, high-volume environment.

- Solution: Implementation of a custom-designed, robust nylon protective cloth organ bellow cover with a heavy-duty PVC coating and integrated internal stiffeners. The design was optimized for dynamic operations at speeds up to 100 m/min, ensuring minimal noise and maximum protection.

- Outcome: Maintenance intervals extended from bi-monthly to once every six months, reducing costs by 75%. Machine precision was consistently maintained, leading to a 15% reduction in scrap rate. The service life of the linear guides was projected to increase by 200%.

Case Study 2: Automated Palletizing System in Food Processing

A food processing plant experienced contamination risks and premature wear of robotic linear actuators in their automated palletizing area due to airborne food particles and frequent washdown cycles. Standard covers were susceptible to bacterial growth and degradation from cleaning agents.

- Solution: A bespoke organ bellow cover manufactured from food-grade, anti-bacterial nylon fabric with a seamless, weld-sealed construction to prevent any ingress. The material was specifically chosen for its resistance to common industrial cleaning chemicals (e.g., diluted chlorine solutions) and high-pressure washdowns.

- Outcome: Achieved compliance with HACCP standards, eliminating contamination risks from the protective cover. The lifespan of the robotic actuators increased by 150%, and cleaning time for the covers was reduced due to their non-porous, easy-to-clean surface.

Figure 5: Customized bellow covers integrated into robotic systems for specific industrial applications.

Ensuring Trust: Certifications, Warranty, and Support

Trust is foundational in B2B relationships, particularly when dealing with critical machine components. Reputable suppliers of protective bellow covers demonstrate trustworthiness through adherence to international standards, robust service commitments, and transparent policies.

Quality Assurance and Certifications

A commitment to quality is validated through globally recognized certifications. Manufacturers operating under ISO 9001 quality management systems ensure consistent product quality, from material sourcing to final inspection. Products typically conform to CE marking directives for European markets and RoHS/REACH compliance for environmental safety, affirming responsible manufacturing practices and material selection.

Lead Time and Fulfillment

Efficient lead times are critical for minimizing project delays and machine downtime. Agilechains.com typically offers standard lead times of 2-4 weeks for customized protective bellows, with expedited options available for urgent requirements. Our streamlined production processes and robust supply chain management ensure reliable fulfillment and global shipping capabilities, minimizing logistical complexities for international clients.

Warranty and After-Sales Support

All protective bellow covers are backed by a comprehensive warranty, typically ranging from 1 to 3 years, covering defects in materials and workmanship. Our dedicated after-sales support team provides technical assistance, installation guidance, and troubleshooting services. We are committed to ensuring optimal performance and maximizing the service life of our protective solutions through continuous customer engagement and support.

Frequently Asked Questions (FAQ)

Q1: How do I select the correct material for my organ bellow cover?

A1: Material selection depends on the operating environment. Consider factors like exposure to coolants, oils, chemicals, high temperatures, UV radiation, and abrasive particles. Nylon with PVC coating is versatile, but specialized fabrics are available for extreme conditions. Consulting with a technical sales engineer is recommended.

Q2: What measurements are needed for a custom bellow cover?

A2: Key dimensions include the maximum extension length, minimum compressed length, overall width and height of the guide or component to be covered, and mounting interface details (e.g., flange dimensions, hole patterns). Providing detailed CAD drawings or existing cover specifications is ideal.

Q3: How do I install an organ bellow cover?

A3: Installation typically involves securing the end plates or mounting flanges to the fixed and moving parts of the machine using screws, clamps, or Velcro. Proper alignment and ensuring free movement without obstruction are crucial. Detailed installation guides are provided with each custom order, and technical support is available.

Q4: What is the typical service life of a nylon protective cloth bellow cover?

A4: Service life can vary significantly based on material, operating speed, environmental conditions, and maintenance. However, high-quality nylon protective cloth bellows are designed for millions of cycles, typically providing several years of reliable protection under normal industrial operating conditions. Regular inspection and cleaning can further extend their lifespan.

References

- International Organization for Standardization (ISO) 9001: Quality Management Systems.

- American National Standards Institute (ANSI) B11.19: Performance Requirements for Safeguarding.

- ASTM International D412: Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension.

- ASTM International D2240: Standard Test Method for Rubber Property—Durometer Hardness.

- IEC 60529: Degrees of Protection Provided by Enclosures (IP Code).

- European Committee for Standardization (CEN) EN ISO 12100: Safety of machinery – General principles for design – Risk assessment and risk reduction.