Ensuring Peak Performance Through Proper CNC Bellow Cover Installation

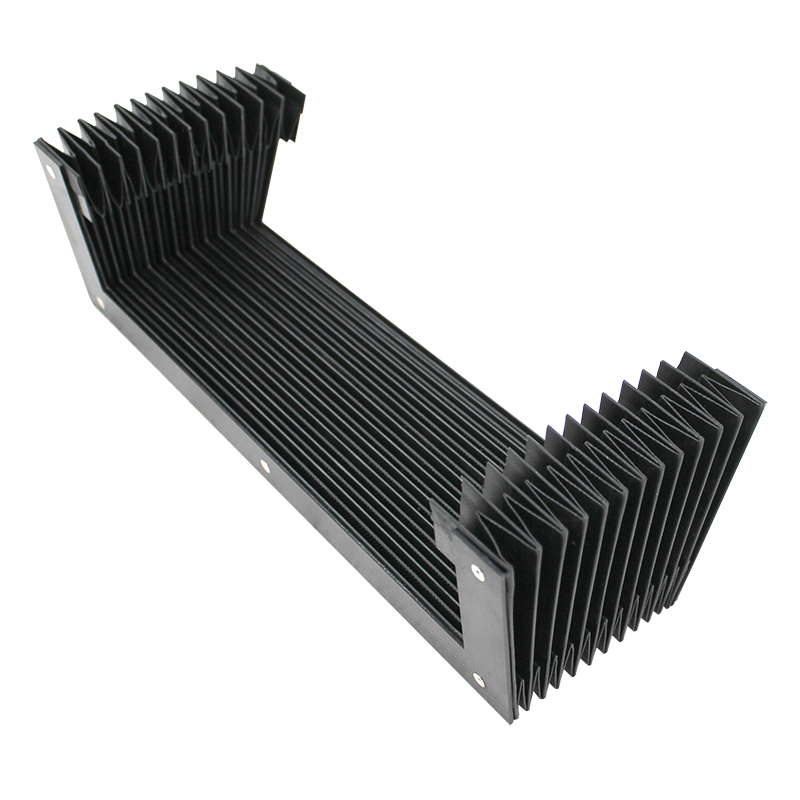

In the high-stakes environment of CNC machining, a CNC bellow cover, or rubber bellow cover is only as effective as its installation. Even the most robustly engineered cover will fail prematurely if mounted incorrectly, leading to costly machine downtime, guide rail damage, and frequent, unplanned replacements. For wholesale buyers managing large fleets, standardizing correct installation practices isn't just maintenance – it's a strategic imperative for maximizing machine uptime, protecting capital investment, and optimizing the total cost of ownership across hundreds of machines. Proper installation transforms this essential shield from a potential liability into a guarantee of long-term reliability.

Shijiazhuang Agile company is established since 2008. We got more than 13 years experience in the production of drag chain, guide rail bellow cover, nylon corrugated bellow pipe and related products. Our products focus on cable protection, rail protection in the reciprocating motion. We got about 100 employees and our factory is located in Yanshan county of Hebei province, and got about 6500 square meters’ production area. Our office is located at Shijiazhuang city, with about 300 square meters’ area. It is about 400 kilo meters from Beijing for location. Quality first is our idea. We put prior importance in quality control. At the same time we are trying much harder to control our price within reasonable scope.

Pre-Installation Preparation: Setting the Stage for CNC Bellow Cover Success -h2

Success begins long before the first fastener is tightened. Meticulous preparation prevents most common failures:

- Precise Dimensional Verification:Double-check the CNC bellow cover(https://www.agilechains.com/cnc-reinforced-protective-rubber-custom-organ-bellow-cover.html) dimensions (fully extended length, compressed height, width, internal clearance) against the machine axis specifications. Ensure the cover matches the machine model and axis configuration exactly. Wholesale orders require rigorous cross-checking against shipment manifests.

- Thorough Machine Cleaning & Inspection:Remove all chips, coolant residue, and debris from the mounting surfaces, guide rails, and ball screw. Inspect for burrs or damage on mounting points that could compromise the seal or tear the rubber bellow cover. A clean environment is critical.

- Gathering Correct Tools & Hardware:Use the manufacturer-recommended fasteners, sealants (if specified), and tools. Avoid substituting inferior hardware, especially for wholesale installations where consistency is key. Ensure any provided mounting brackets or profiles are correct.

Step-by-Step Installation Mastery for CNC Bellows -h2

Following a disciplined sequence ensures optimal performance and longevity:

- Secure the Fixed End First:Mount the stationary end of the CNC bellow cover firmly and squarely to the machine structure, ensuring a debris-tight seal. Verify alignment parallel to the axis of travel. Use all provided fasteners and ensure brackets are flush.

- Positioning the Moving End:Connect the moving end to the carriage only after the fixed end is secure. Ensure the attachment point allows the rubber bellow cover to move freely without binding or lateral stress throughout its entire stroke. Leave fasteners slightly loose initially for final adjustment.

- Achieving Perfect Alignment & Tension:Manually traverse the machine axis through its full range. Observe the CNC bellowscarefully. It should expand and contract smoothly, evenly, and without twisting, sagging, or rubbing against machine components. Adjust the moving end position and tension as needed. The cover should be taut but not stretched when extended.

- Final Tightening & Sealing:Once perfect alignment and movement are confirmed, securely tighten all fasteners on the moving end. Apply recommended sealant around mounting flanges if specified, ensuring a complete barrier against ingress. Double-check fastener torque.

Avoiding Critical Pitfalls: Why CNC Bellow Covers Fail Prematurely -h2

Understanding common mistakes helps prevent costly downtime and replacements:

- Pinching and Binding:The mostfrequent killer. Caused by misalignment, insufficient clearance, or allowing the CNC bellow cover to get trapped between machine parts or its own folds during travel. Leads to immediate tears or accelerated wear.

- Over-Compression or Over-Extension:Forcing the rubber bellow coverbeyond its designed compressed height or extended length stresses folds and seams, causing cracking, delamination, or detachment from mounts.

- Twisting and Misalignment:Mounting the cover crookedly or allowing it to rotate during operation creates uneven stress distribution, internal abrasion, and premature failure. Careful alignment during installation is non-negotiable.

- Inadequate Mounting or Loose Hardware:Using incorrect or insufficient fasteners, or failing to tighten them securely, allows the CNC bellowsto shift, vibrate, or detach. Vibration loosens hardware over time – periodic checks are vital, especially after initial run-in.

- Ignoring Internal Clearance:Ensure the CNC bellow coverhas sufficient internal space around the ball screw or guide rail. Contact causes abrasion and can hinder axis movement. Verify clearance in both compressed and extended states.

Frequently Asked Questions About CNC Bellow Cover Installation -h2

Can I install a CNC bellow cover myself, or is a technician essential?-h3

While technically possible for skilled personnel using the manufacturer's instructions, complex machines or critical axes benefit from trained technician installation, especially for high-value assets covered under wholesale contracts. Proper training is key for in-house teams.

How tight should the CNC bellows be when extended?-h3

The CNC bellow cover should be taut but never stretched. There should be no visible sagging or wrinkles when fully extended, but applying tension to pull it tighter than its natural extended length creates damaging internal stress. Follow the manufacturer's guidance on "pre-tension."

What's the biggest sign of incorrect CNC bellows installation I can spot quickly?-h3

Uneven folding during travel is a major red flag. If the folds don't open and close symmetrically and smoothly across the entire width of the rubber bellow cover, it indicates misalignment, pinching, or improper tension, demanding immediate correction.

How do I handle CNC bellows installation on a machine with very limited space?-h3

Consult the manufacturer before ordering. Special low-profile CNC bellows designs exist. During installation, extra care is needed with alignment and ensuring internal clearance. Precisely following the installation sequence and potentially using custom mounting brackets are crucial in confined spaces for CNC bellow covers.

Are there special considerations for installing large or heavy-duty rubber bellow covers?-h3

Absolutely. Larger/heavier covers may require temporary supports during installation to prevent strain or dropping. Ensure mounting structures are robust enough. Pay extra attention to alignment over longer spans. Multiple installers may be needed for safety and precision. Verify the machine structure can handle the dynamic load.

Mastering CNC bellow cover installation is a critical, often underestimated, engineering discipline. By adhering to rigorous preparation, a meticulous step-by-step process, avoiding common traps, and implementing vigilant post-installation checks, wholesale buyers unlock the full potential of their investment. This translates directly into maximized machine uptime, dramatically extended cover lifespan reducing replacement frequency and inventory costs, and superior protection for expensive linear components. For large-scale operations, standardizing these best practices across the maintenance team isn't just good practice – it's fundamental to achieving peak efficiency, minimizing total cost of ownership, and safeguarding productivity through the reliable performance of every CNC bellow cover, and rubber bellow cover on the shop floor.