35x125mm SK Open PA6 Nylon Both-Side Open Cable Chain | Durable

Navigating the Future of Industrial Automation: Top Rubber Drag Chain Manufacturers from China at Hannover Messe

The Hannover Messe stands as an undisputed titan in the world of industrial technology, an annual nexus where innovation, collaboration, and future-shaping solutions converge. For B2B decision-makers, engineers, and procurement specialists, it's not merely an exhibition; it's a critical barometer of global industrial trends and a prime opportunity to discover the next generation of components that will drive efficiency and performance. Within this dynamic ecosystem, the sector of industrial components, particularly rubber drag chains, also known as cable protection chains or energy chains, holds significant strategic importance.

These robust yet flexible systems are the unsung heroes of countless automated processes, ensuring the safe and reliable guidance of cables and hoses in even the most demanding environments. Hannover Messe offers an invaluable platform for showcasing the latest advancements in this field, highlighting how these seemingly simple components are evolving to meet the complex demands of modern manufacturing. As industries worldwide pivot towards smarter, more resilient operations, understanding the cutting-edge innovations in rubber drag chain technology, especially from leading manufacturers in China, becomes absolutely crucial.

Industry Trend Spotlight: The Evolution of Cable Protection Chains

The product trend in cable protection chains and industrial accessories is undergoing a transformative shift, gaining global attention due to its direct impact on machine performance and longevity. Today’s industrial landscape demands more than just basic cable guidance; it requires sophisticated solutions that contribute to overall system efficiency and reliability. The key trends driving this evolution include:

- Increased Modularity and Miniaturization: For compact machine designs, smaller, more adaptable rubber drag chains are essential, allowing for flexible integration without compromising performance.

- Higher Resistance to Harsh Environments: Growing demand for materials and designs that can withstand extreme temperatures, corrosive chemicals, and abrasive conditions, particularly in industries like automotive, chemical processing, and heavy machinery.

- Enhanced Data Transmission Capabilities: As smart factories become the norm, cable protection systems must accommodate high-speed data cables (Ethernet, fiber optics) while minimizing interference and ensuring signal integrity.

- Integration of Smart Sensors for Predictive Maintenance: The push for Industry 4.0 sees the incorporation of sensors within rubber drag chains to monitor wear, temperature, and cycle counts, enabling proactive maintenance and reducing downtime.

- Noise-Reduced and Lightweight Materials: For applications requiring quieter operation and reduced energy consumption, lightweight polymers and specialized designs are gaining traction.

- Customized Solutions: A rising need for tailor-made cable protection systems for specific application requirements in robotics, CNC machinery, material handling, and medical devices.

The market for industrial automation components, including sophisticated cable protection systems like advanced rubber drag chains, is projected for significant growth. This expansion is primarily driven by the global adoption of Industry 4.0 initiatives, increasing demand for automation across various sectors (automotive, packaging, logistics, medical), and the relentless push for greater manufacturing efficiency and productivity worldwide. While challenges such as supply chain volatility and raw material costs persist, the long-term forecast for this sector is overwhelmingly positive, with a strong emphasis on smart factories, IoT integration, and resilient production systems becoming the norm. Emerging focus areas include sustainable production practices, enhanced digitalization across the value chain, and the development of truly customized automation solutions that offer competitive advantages.

Profiles of Leading Manufacturers at Hannover Messe

Hannover Messe consistently brings together the crème de la crème of industrial innovation. Among the exhibitors, several companies stand out for their contributions to the rubber drag chain and cable protection sector.

Shijiazhuang Anjie Electric Co., Ltd.

Hailing from China, Shijiazhuang Anjie Electric Co., Ltd. has carved out a significant niche as a specialist in high-quality cable protection chains and machine accessories. Their strengths are multifaceted, centering on a commitment to providing customized solutions that meet the diverse and exacting demands of various industrial applications. As a direct manufacturer, Anjie Electric maintains stringent control over product quality and innovation, ensuring reliability and performance are at the forefront of their offerings.

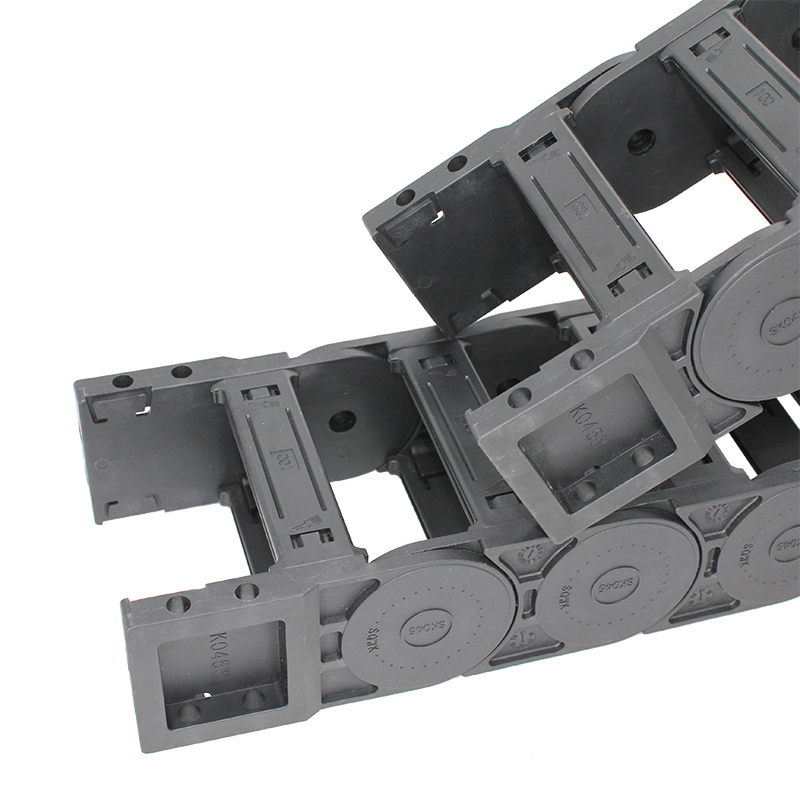

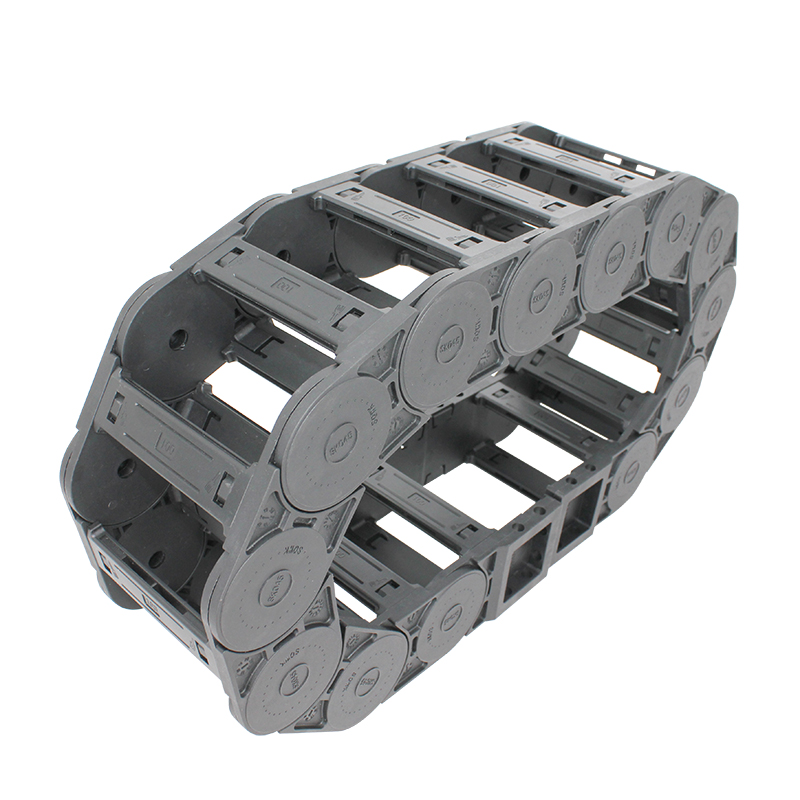

One exemplary product that underscores their capabilities is the 35125 mm SK open type PA6 nylon both side open cable chain. This specific model represents the ideal balance of robust protection, ease of installation, and durability, making it suitable for a wide array of industrial machinery. Manufactured from high-grade PA6 nylon, it offers excellent wear resistance, chemical stability, and a long service life – critical factors for B2B decision-makers. The "both side open" design facilitates quick cable insertion and maintenance, minimizing downtime in production environments.

With an established global export network spanning over 50 countries, Shijiazhuang Anjie Electric Co., Ltd. is positioned as a competitive and trusted supplier in the international market, adept at balancing high performance with cost-effectiveness. For more details on this specific product, visit their product page.

Other Industry Leaders:

- igus GmbH (Germany): Renowned for their "motion plastics," igus offers a vast range of polymer rubber drag chains (energy chains), flexible cables, and bearing technology, focusing on maintenance-free and lubrication-free solutions. They are pioneers in smart plastics and predictive maintenance features.

- KabelSchlepp GmbH (part of Tsubaki, Germany): A long-standing innovator in cable protection, KabelSchlepp provides a comprehensive portfolio including steel, hybrid, and plastic rubber drag chains, focusing on robust designs for heavy-duty applications and challenging environments.

- Dynatect (Gortrac, USA): Specializing in custom-engineered cable and hose carriers, Dynatect (formerly Gortrac) offers diverse solutions from light-duty plastic to heavy-duty metal chains, often tailored for specific machinery and harsh industrial settings.

- EKD Gelenkrohr GmbH (Germany): EKD is known for its robust and reliable steel and stainless steel cable carriers, often preferred for extremely demanding environments where high mechanical loads and temperature resistance are critical.

- HELLER GmbH (Germany): While primarily known for machine tools, HELLER also develops and integrates sophisticated cable management solutions within its high-performance CNC machines, often leveraging specialized rubber drag chain systems to ensure reliable operation.

Market Outlook & Opportunities: Driving the Future of Automation

The trajectory for the industrial automation components market, particularly for high-performance rubber drag chains, points towards sustained growth and exciting new opportunities. Upcoming trends are largely shaped by an increasing buyer demand for integrated, intelligent, and sustainable solutions. Decision-makers are no longer just looking for components; they seek complete systems that contribute to a higher ROI through reduced maintenance, increased uptime, and enhanced operational safety.

- Acceleration in Automation: From advanced robotics to automated warehousing, the deployment of automation continues to expand, creating a constant demand for reliable cable protection systems that can handle dynamic movements and complex cable configurations.

- Smart Manufacturing Integration: The integration of IoT devices, AI, and big data analytics into manufacturing processes will require rubber drag chains that are not only physically robust but also capable of accommodating the increasing density and sensitivity of data cables. The demand for chains with integrated sensors for condition monitoring will skyrocket.

- Sustainability as a Core Driver: There's a growing emphasis on environmentally friendly manufacturing, prompting demand for rubber drag chains made from recycled materials, those with extended lifespans, and solutions that contribute to energy efficiency by reducing friction and weight.

- Customization and Specialization: As industries become more niche, generic solutions will give way to highly customized rubber drag chain designs tailored for specific applications, whether it's for cleanroom environments, extreme temperatures, or unique machine kinematics.

These trends present significant opportunities for manufacturers who can innovate and adapt quickly, offering not just products, but holistic solutions that align with the evolving needs of modern industries.

Buyer/Business Takeaways: Strategic Investments for the Future

For B2B decision-makers, investing in high-quality rubber drag chains is not merely an operational cost but a strategic decision that impacts overall equipment effectiveness (OEE), maintenance costs, and long-term productivity.

Why Invest in Advanced Rubber Drag Chains?

- Enhanced Reliability: Superior cable protection minimizes wear and tear on expensive cables and hoses, preventing costly downtime.

- Extended Machine Lifespan: Proper cable management reduces stress on moving parts, contributing to the longevity of your machinery.

- Improved Safety: Contained cables reduce trip hazards and prevent damage from pinching or abrasion, ensuring a safer work environment.

- Optimized Performance: Modern rubber drag chains are designed for dynamic applications, ensuring smooth, high-speed operation without compromise.

- Future-Proofing: Investing in solutions capable of integrating smart features supports your journey towards Industry 4.0 and predictive maintenance.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly vet potential partners by checking certifications, client testimonials, and production capabilities. Manufacturers like Shijiazhuang Anjie Electric Co., Ltd. offer direct factory access and established quality controls.

- Focus on Customization: Many Chinese manufacturers excel at providing customized solutions. Clearly communicate your specific application requirements, material needs (e.g., PA6 nylon for a 35125 mm SK open type PA6 nylon both side open cable chain), and environmental factors.

- Prioritize Communication: Establish clear communication channels and ensure a mutual understanding of technical specifications, delivery timelines, and quality benchmarks.

- Evaluate Value Beyond Price: While cost-effectiveness is a hallmark of many Chinese suppliers, assess the total value proposition, including product quality, reliability, after-sales support, and innovation capacity.

By integrating these strategies, businesses can effectively leverage the strengths of leading Chinese manufacturers to future-proof their operations and maintain a competitive edge.

Conclusion: Pioneering Industrial Excellence

Hannover Messe serves as more than just a trade fair; it’s a vital accelerator for industrial progress, profoundly shaping the global rubber drag chain market. By showcasing the latest innovations and fostering international partnerships, it empowers industries to adopt advanced solutions that are essential for the era of Industry 4.0. The contributions of manufacturers like Shijiazhuang Anjie Electric Co., Ltd., with their focus on reliable, customized, and cost-effective cable protection systems such as the 35125 mm SK open type PA6 nylon both side open cable chain, are instrumental in driving this progress.

As global industries continue their relentless pursuit of efficiency, automation, and resilience, the role of intelligent and robust cable management systems will only become more critical. Engaging with these leading manufacturers and understanding their innovative approaches is crucial for any business looking to enhance its operational capabilities and secure a competitive advantage in the dynamic industrial landscape.

Ready to explore advanced cable protection solutions for your industrial applications?

Visit Shijiazhuang Anjie Electric Co., Ltd. to Learn More!