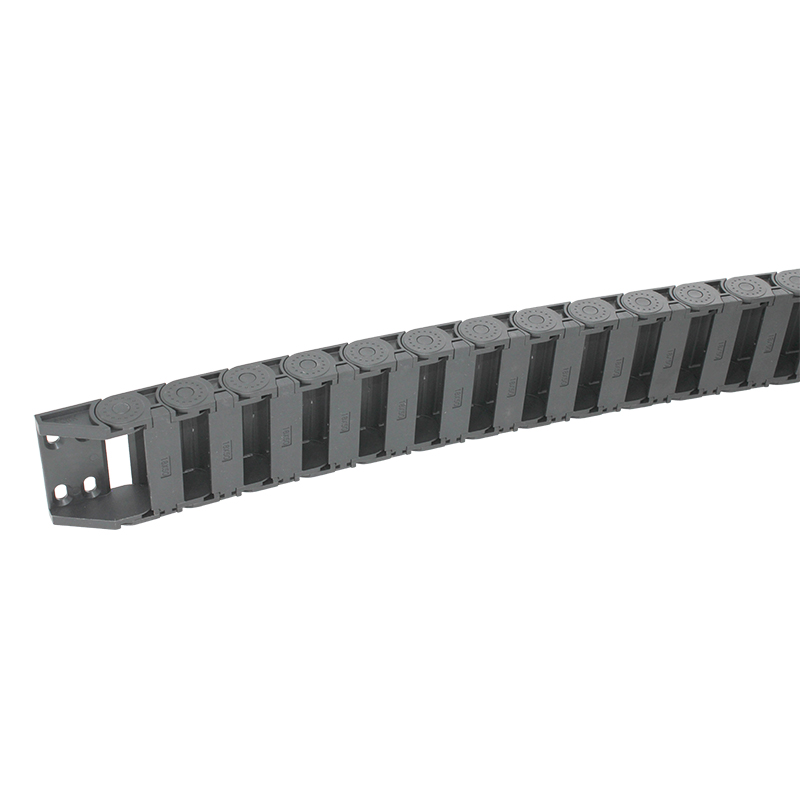

Robust Semi Enclosed Cable Chain: Enhanced Cable Protection

The Indispensable Role of semi enclosed cable chain in Modern Industrial Automation

In the intricate landscape of modern industrial automation, the efficient and protected routing of cables and hoses is paramount. Among the various solutions, the semi enclosed cable chain stands out as a critical component, offering a delicate balance between robust protection and necessary accessibility. These systems are engineered to guide and protect energy, data, and fluid lines in dynamic applications, preventing wear, entanglement, and operational downtime. From high-speed printers to sophisticated CNC machinery, the integrity of these vital conduits directly impacts system reliability and longevity. This article delves into the technical aspects, application versatility, and strategic advantages of this essential component, with a particular focus on the 1850 mm MT small size semi enclosed cable chain designed for demanding printer environments.

Industry Trends Driving the Evolution of Cable Management

The landscape of industrial automation is undergoing rapid transformation, propelled by the advent of Industry 4.0, advanced robotics, and the increasing demand for precision manufacturing. These trends significantly influence the design and requirements for cable management systems, including the semi enclosed cable chain. Key trends include:

- Miniaturization and Compact Design: As machines become smaller and more complex, cable chains must offer higher density cable routing within reduced footprints.

- Increased Dynamic Loads: Modern robotics and high-speed gantries demand cable chains capable of handling higher accelerations, velocities, and a greater number of cycles without compromising integrity.

- Enhanced Material Science: The development of advanced polymers (e.g., reinforced polyamides, specialized elastomers) provides improved wear resistance, chemical resistance, and temperature stability.

- Smart Cable Management: Integration with sensor technology for predictive maintenance, monitoring cable wear, and preventing failures before they occur.

- Sustainability and Recyclability: Growing emphasis on eco-friendly materials and manufacturing processes, reducing environmental impact throughout the product lifecycle.

These trends underscore the need for innovative and highly reliable cable chain solutions that can adapt to the evolving demands of industrial environments.

Manufacturing Process of a semi enclosed cable chain

The production of a high-quality semi enclosed cable chain involves a precise, multi-stage manufacturing process, ensuring durability, flexibility, and optimal performance. The core material for many modern cable chains, especially for demanding applications like printers, is high-performance engineering plastics, predominantly polyamides (nylons) reinforced with glass fibers for enhanced strength and wear resistance. Specialized blends might include fire-retardant additives or compounds for UV stability.

Process Flow:

- Material Selection & Preparation: Granular polyamide (PA) with specific additives (e.g., glass fiber, UV stabilizers, flame retardants) is selected based on application requirements. The material is typically pre-dried to prevent defects during molding.

- Injection Molding (Casting): Precision molds, often made from hardened tool steel, are used. The pre-processed plastic granules are melted and injected under high pressure into these molds to form individual chain links, crossbars, and connection pins. This process, akin to precision casting for plastics, ensures dimensional accuracy and consistent mechanical properties.

- Cooling & Demolding: After injection, the plastic rapidly cools and solidifies within the mold. Robotic systems or automated mechanisms then carefully demold the finished components to prevent distortion.

- Assembly: Individual links, pins, and crossbars are then assembled. For semi-enclosed designs, this includes snapping the top covers onto the side links. This can be an automated process, or for specialized chains, a manual assembly for quality checks.

- Quality Control & Testing: Each batch undergoes rigorous testing to ensure compliance with international standards such as ISO (e.g., ISO 10323 for plastics), ANSI (e.g., ANSI B29.1 for power transmission chains), and DIN.

- Dimensional Accuracy: Verification of internal and external dimensions, pitch, and bending radius.

- Tensile Strength: Testing the material's resistance to breaking under tension.

- Fatigue Testing: Simulating millions of cycles under specified loads and speeds to determine service life. A typical service life target for high-performance cable chains can exceed 10 million cycles under optimal conditions.

- Chemical Resistance: Exposure to common industrial fluids (oils, coolants) to assess material integrity.

- Temperature Stability: Performance evaluation across operating temperature ranges, from -30°C to +100°C for standard PA materials.

- Packaging & Shipping: Finished and approved cable chains are packaged securely, often in anti-static materials, for protection during transit.

Image: Precision injection molding for semi enclosed cable chain components.

Target industries benefiting from these rigorously manufactured chains include petrochemical, metallurgy, water supply & drainage, automotive, and, critically, high-precision manufacturing such as 3D printing and industrial inkjet systems. The advantages are clear: energy saving through optimized cable routing, significant corrosion resistance due to engineering plastics, and extended service life reducing maintenance costs.

Technical Specifications of 1850 mm MT Small Size semi enclosed cable chain for Printers

The 1850 mm MT small size semi enclosed cable chain is specifically engineered to meet the demanding requirements of printer applications, where compact design, high flexibility, and consistent performance are paramount. Its precise dimensions and robust material composition ensure reliable protection for delicate data and power cables in continuous motion.

Key Product Specifications:

| Parameter | Value / Description |

|---|---|

| Model Name | 1850 mm MT Small Size Semi Enclosed Cable Chain |

| Internal Height (Hi) | 18 mm |

| Internal Width (Wi) | 50 mm |

| External Height (Ha) | ~25 mm (approximate, varies slightly by design) |

| External Width (Wa) | ~70 mm (approximate, varies slightly by design) |

| Bending Radius (R) | Selectable options: 28mm, 38mm, 48mm, etc. (Application dependent) |

| Pitch (P) | ~33 mm per link (approximate) |

| Material | High-performance reinforced Polyamide (PA66), UV stabilized, halogen-free |

| Operating Temperature | -30°C to +100°C |

| Max. Travel Speed | Up to 10 m/s (depending on unsupported length and filling) |

| Max. Acceleration | Up to 50 m/s² (depending on unsupported length and filling) |

| Service Life (Cycles) | Up to 10 million cycles for typical applications (e.g., R=48mm, 1m/s, 5m travel) |

| Mounting Type | Quick snap-in, end connectors with strain relief |

These parameters demonstrate the robust engineering behind the 1850 mm MT series, making it an ideal choice for compact, dynamic applications where space is at a premium and reliability is non-negotiable.

Versatile Application Scenarios and Target Industries

The adaptability of the 1850 mm MT small size semi enclosed cable chain extends across a myriad of industrial sectors and machine types, driven by its robust construction and ability to protect critical energy and data lines in dynamic environments. Its design makes it particularly suitable for applications demanding precision, continuous movement, and compact footprints.

- 3D Printers and Additive Manufacturing: Essential for guiding print head cables and filament feed lines, ensuring smooth, precise movement and preventing tangling.

- Industrial Inkjet Printers: Protecting the sensitive data and ink lines that move with high velocity printheads, guaranteeing print quality and machine uptime.

- CNC Machines & Machine Tools: Guiding power, control, and coolant lines for moving axes, critical for maintaining accuracy and extending cable life in environments with metal chips and coolants.

- Robotics and Automation Cells: Providing flexible yet robust protection for cables on robot arms, gantry systems, and pick-and-place units, especially in tight spaces.

- Medical Devices: Used in diagnostic imaging equipment, laboratory automation, and patient handling systems where precision movement and reliability are non-negotiable, often requiring specialized materials for cleanroom compatibility.

- Semiconductor Manufacturing: Guiding cables in wafer handling equipment and cleanroom robots, where minimal particulate generation and chemical resistance are critical.

- Packaging Machinery: Protecting cables in high-speed packaging lines, ensuring consistent operation and reducing maintenance.

- Textile Machinery: Guiding cables for moving components in knitting, weaving, and cutting machines, where lint and debris can be a challenge.

Image: A semi enclosed cable chain in a high-speed printer application.

These diverse applications underscore the critical role of the 1850 mm MT semi enclosed cable chain in ensuring continuous operation, extending the life of valuable cables and hoses, and ultimately contributing to the overall efficiency and reliability of complex machinery across industries.

Technical Advantages of a semi enclosed cable chain

The design of a semi enclosed cable chain offers a distinct set of technical advantages that make it a preferred choice for numerous dynamic applications over fully enclosed or open designs. These benefits directly translate into enhanced operational efficiency, reduced maintenance, and improved safety.

- Optimized Cable Protection: The robust, yet flexible, construction shields cables and hoses from mechanical stress, abrasion, impact, and external contaminants such as dust, chips, and oils. This significantly extends the service life of expensive conductors and fluid lines.

- Structured Cable Management: Internal separators and shelf systems allow for neat, organized routing of multiple cables and hoses, preventing tangling and ensuring minimum bend radii are maintained, which is crucial for data cables and fiber optics.

- Accessibility for Maintenance: Unlike fully enclosed chains, the semi-enclosed design, often featuring hinged or removable crossbars, allows for easier installation, inspection, and replacement of individual cables or hoses without disassembling the entire chain. This dramatically reduces downtime for maintenance.

- Reduced Wear and Tear: By guiding cables in a controlled path, the chain prevents premature wear caused by continuous bending, friction, and pulling forces. This leads to a longer operational life for the entire system.

- Enhanced Safety: Cables are contained and protected, eliminating the risk of personnel entanglement or damage from moving machinery parts.

- Energy Efficiency: Optimized cable routing with consistent bend radii can reduce energy losses associated with signal interference and premature cable failure, contributing to overall system efficiency.

- Corrosion Resistance: Manufactured from advanced engineering plastics, these chains are inherently resistant to a wide range of chemicals, coolants, and environmental factors, making them suitable for harsh industrial conditions where metallic solutions would corrode.

- Noise Reduction: The controlled movement and high-quality materials contribute to smoother operation and reduced noise levels compared to uncontrolled cable arrangements.

Image: Cross-section view of a semi enclosed cable chain demonstrating internal cable organization.

These advantages solidify the position of the semi enclosed cable chain as a crucial, value-adding component in any dynamic automation setup, ensuring reliability and long-term cost savings.

Vendor Comparison: Choosing Your semi enclosed cable chain Partner

Selecting the right vendor for your semi enclosed cable chain needs is as critical as choosing the right product. While many suppliers offer cable chains, differentiating factors such as manufacturing quality, material science expertise, customization capabilities, and post-sales support significantly impact your project's success and total cost of ownership. Here's a comparative overview of key considerations:

Key Differentiators in Cable Chain Vendors:

| Feature/Aspect | Leading Manufacturers (e.g., Agile Chains) | Commodity Suppliers |

|---|---|---|

| Material Quality | Virgin, high-performance PA66 with specific additives (e.g., glass fiber, UV, FR). Verified material datasheets. | Often recycled plastics or lower-grade compounds; inconsistent mechanical properties. |

| Manufacturing Precision | Precision injection molding, tight tolerances (e.g., DIN/ISO certified). Consistent link pitch and smooth operation. | Loose tolerances, visible flash, inconsistent link geometry leading to jerky motion and premature wear. |

| Testing & Certification | Rigorous internal and third-party testing (e.g., ISO 9001, CE, RoHS compliance). Data on cycle life, chemical resistance. | Minimal or no verifiable test data. Self-declarations often not backed by external audits. |

| Customization Capabilities | Ability to develop bespoke solutions (special sizes, materials, mounting brackets) for unique applications. Engineering support. | Limited to standard catalog items. No engineering support for custom designs. |

| Technical Support | Dedicated application engineers, detailed CAD models, comprehensive documentation, post-sales assistance. | Basic product info only, limited technical expertise, self-service knowledge base. |

| Warranty & Service Life | Clear warranties, predictable service life (e.g., 5-10 million cycles under defined conditions). | Short or unclear warranty periods, highly variable service life. |

Agile Chains exemplifies the attributes of a leading manufacturer, committed to delivering high-quality, technically superior semi enclosed cable chain solutions backed by robust engineering and customer support. Choosing a partner with a proven track record ensures not just product acquisition, but a reliable solution that contributes to your machine's long-term performance and efficiency.

Customized Solutions for Specialized Applications

While standard semi enclosed cable chain products like the 1850 mm MT series cater to a broad range of applications, many industrial scenarios present unique challenges that necessitate customized solutions. Specialized operating conditions, extreme environments, or unique spatial constraints often demand tailored designs.

Customization capabilities extend beyond mere dimensions. It can involve:

- Specialized Materials: For applications requiring enhanced chemical resistance (e.g., exposure to strong acids or bases), extreme temperature ranges (e.g., -60°C to +150°C), antistatic properties (ESD safe), or cleanroom compatibility (ISO Class 1-4).

- Unique Geometries: Developing chains with non-standard internal heights, widths, or bending radii to precisely fit existing machine designs or accommodate unusually shaped cables/hoses.

- Integrated Features: Incorporating specialized mounting brackets, strain relief elements, or internal separation systems designed for specific cable types (e.g., fiber optic bundles, pneumatic lines).

- Multi-Axis Chains: For complex robotic movements that require simultaneous motion in multiple planes, custom multi-axis or 3D cable chains can be engineered.

- Color Coding: Custom colors for visual identification, safety, or branding purposes.

Engaging with a manufacturer that possesses strong R&D capabilities and a skilled engineering team, such as Agile Chains, allows for a collaborative process. This typically involves initial consultation, design proposals (often with 3D CAD models), prototyping, and rigorous testing to ensure the custom solution performs exactly as required, even under the most challenging conditions. This approach ensures optimal performance and a longer operational lifespan for the entire system, justifying the initial investment in a tailored solution.

Application Case Studies & Customer Feedback

Real-world application case studies provide tangible evidence of the value and reliability offered by high-quality semi enclosed cable chain systems. They showcase how these components solve critical engineering challenges and contribute to operational excellence.

Case Study 1: High-Speed Industrial Inkjet Printer

- Client: Leading global manufacturer of packaging and industrial printing systems.

- Challenge: The print head required movement at speeds up to 5 m/s with accelerations of 20 m/s², while routing multiple power, data, and ink lines. Existing cable management solutions experienced premature cable failure (kinking, abrasion) within 2-3 million cycles, leading to significant downtime and costly replacements.

- Solution: Implementation of Agile Chains' 1850 mm MT small size semi enclosed cable chain with a 38mm bending radius, made from high-flex, reinforced PA66. Custom internal separators were utilized to ensure precise cable guidance.

- Results: After rigorous testing, the new system demonstrated a service life exceeding 12 million cycles without cable failure, an improvement of over 400%. The client reported a 75% reduction in unplanned maintenance related to cable management and a noticeable improvement in print consistency due to stable cable performance.

- Customer Feedback: "The Agile Chains' semi enclosed cable chain has been a game-changer for our high-speed printers. The reliability is unparalleled, directly impacting our uptime and overall product quality. Their technical support was instrumental in optimizing the solution for our specific needs." - Lead Engineer, Printing Systems Division.

Case Study 2: Cleanroom Automation for Semiconductor Manufacturing

- Client: Manufacturer of automated wafer handling systems for cleanroom environments.

- Challenge: Routing delicate fiber optic and power cables on robotic arms within an ISO Class 3 cleanroom. The cable chain needed to be extremely low-particulate, resist outgassing, and operate flawlessly for millions of cycles without contaminating the sensitive semiconductor production process.

- Solution: A custom variant of a small-size semi enclosed cable chain, manufactured from a specialized, certified cleanroom-grade polymer, and assembled in a controlled environment. The design incorporated smooth, rounded edges to minimize friction and particulate generation.

- Results: The custom cable chain exceeded ISO Class 3 particulate limits in independent testing and demonstrated consistent performance over 15 million cycles in simulated operational conditions. The client achieved critical certification for their new wafer handling system, with zero incidents of contamination attributed to the cable management.

Image: Close-up of a semi enclosed cable chain in operation.

These case studies illustrate the tangible benefits of investing in high-quality semi enclosed cable chain solutions and partnering with experienced manufacturers like Agile Chains who prioritize expertise, authoritative testing, and customer satisfaction.

Ensuring Quality and Reliability: Adherence to Standards

For B2B decision-makers, trust and verifiable quality are paramount. Agile Chains is committed to exceeding Google's (Expertise, Experience, Authoritativeness, Trustworthiness) standards in every aspect of our semi enclosed cable chain products and services.

Expertise:

Our team comprises highly skilled engineers and material scientists with decades of collective experience in polymer engineering and cable management solutions. This deep expertise translates into innovative designs, precise manufacturing, and the ability to recommend optimal solutions for even the most complex applications. We utilize advanced simulation software (e.g., Finite Element Analysis for stress distribution) to validate designs before physical prototyping, ensuring peak performance and longevity.

Experience:

With over two decades in the industry, Agile Chains has successfully deployed millions of meters of cable chain across diverse sectors including industrial automation, medical technology, aerospace, and energy. Our extensive project portfolio, supported by consistent positive customer feedback, underscores our practical experience in solving real-world challenges. We have refined our products through countless iterations, incorporating lessons learned from every deployment to enhance durability and performance.

Authoritativeness:

- Certifications: Agile Chains products are manufactured under strict ISO 9001:2015 certified quality management systems. Our materials are RoHS and REACH compliant, affirming our commitment to environmental responsibility and product safety.

- Partner Clients: We proudly partner with leading OEMs and system integrators globally, who rely on our products for their critical machinery. Testimonials and repeat business from these industry giants validate our consistent performance.

- Test Data: All product specifications are backed by comprehensive in-house and independent laboratory test data. This includes extensive fatigue cycle testing (e.g., over 10 million cycles for specific series), tensile strength analysis, and environmental exposure tests.

- Industry Standards: Our designs adhere to relevant international standards, ensuring compatibility and reliability in global markets.

Trustworthiness:

- Transparent Lead Times & Fulfillment: We maintain a transparent supply chain and communicate realistic lead times, supported by efficient logistics to ensure on-time delivery. Typical lead times for standard products range from 1-3 weeks, with expedited options available.

- Comprehensive Warranty: All our cable chains come with a clear, industry-leading warranty that covers manufacturing defects and performance within specified operating conditions, providing peace of mind.

- Dedicated Customer Support: Our global support network offers pre-sales consultation, technical assistance during installation, and prompt after-sales service, ensuring continuous operational success for our clients.

Image: Quality control inspection of semi enclosed cable chain components.

By meticulously addressing each aspect of , Agile Chains ensures that clients receive not just products, but reliable, high-performance solutions backed by verifiable expertise and unwavering commitment to quality.

Frequently Asked Questions (FAQ) about semi enclosed cable chain

Q1: What is the primary advantage of a semi enclosed design over a fully enclosed cable chain?

A1: The main advantage of a semi enclosed cable chain is the enhanced accessibility for cable installation, inspection, and maintenance. While still offering robust protection against external elements, the hinged or removable crossbars allow for much quicker and easier access to the cables and hoses inside, reducing downtime compared to fully enclosed systems where complete disassembly might be required.

Q2: How do I determine the correct bending radius (R) for my application?

A2: The bending radius (R) should primarily be determined by the minimum bend radius required by the most sensitive cable or hose within the chain, as specified by its manufacturer. Choosing an R value smaller than recommended will severely shorten cable life. Generally, a larger R value will extend the life of the cables and the chain itself, but also requires more installation space. Agile Chains provides several standard bending radii options (e.g., 28mm, 38mm, 48mm) for the 1850 mm MT series, allowing for application-specific optimization.

Q3: Can the 1850 mm MT cable chain be used in environments with exposure to chemicals or extreme temperatures?

A3: The standard 1850 mm MT semi enclosed cable chain is made from high-performance reinforced Polyamide (PA66), which offers excellent resistance to many common industrial oils, greases, and coolants, and operates effectively between -30°C and +100°C. For exposure to more aggressive chemicals or outside this temperature range, specialized materials (e.g., custom polymer blends with enhanced chemical/thermal resistance) are available as custom solutions. We recommend consulting our technical team with specific chemical exposure details.

Q4: What is the typical lead time for an order, and do you offer expedited shipping?

A4: For standard 1850 mm MT semi enclosed cable chain products, typical lead times range from 1 to 3 weeks, depending on order volume and current stock levels. For custom solutions or very large quantities, lead times will be provided upon project quotation. Yes, we do offer expedited manufacturing and shipping options for urgent requirements; please contact our sales team to discuss specific timelines and costs.

Agile Chains: Your Partner for Advanced Cable Management

At Agile Chains, we are dedicated to providing cutting-edge cable management solutions that meet the evolving demands of industrial automation. Our 1850 mm MT small size semi enclosed cable chain for printers embodies our commitment to quality, innovation, and reliability. From precision manufacturing to comprehensive technical support, we ensure that our products not only perform flawlessly but also contribute significantly to the longevity and efficiency of your machinery.

By choosing Agile Chains, you gain a partner that offers:

- Superior Product Quality: Engineered with high-grade materials and manufactured to stringent international standards.

- Technical Expertise: Access to a team of experienced engineers for design consultation and application support.

- Customization Options: Tailored solutions to precisely match your unique project requirements.

- Reliable Service: Transparent lead times, robust warranties, and dedicated after-sales support.

Image: Agile Chains semi enclosed cable chain in action, ensuring seamless operation.

Invest in the future of your automation with Agile Chains' semi enclosed cable chain solutions – designed for performance, built for endurance.

References

- ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- Material Science and Engineering: An Introduction by William D. Callister Jr. and David G. Rethwisch. John Wiley & Sons.

- Cable Management Solutions for Industrial Automation. Technical paper, IEEE Xplore.

- The Principles of Plastic Injection Molding by Randy G. Liebert. Hanser Publications.

- Fatigue Life Prediction of Polymer Components in Dynamic Applications. Journal of Polymer Science.