anti-fire dust elastic armor shield steel bellow cover OEM

Anti-fire Dust Elastic Armor Shield Steel Bellow Cover is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of mechanical components. This article explores how Shijiazhuang Anjie Electric Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Anti-fire Dust Elastic Armor Shield Steel Bellow Cover Overview

- Benefits & Use Cases of Anti-fire Dust Elastic Armor Shield Steel Bellow Cover in Manufacturing of mechanical components

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Anti-fire Dust Elastic Armor Shield Steel Bellow Cover from Shijiazhuang Anjie Electric Co., Ltd.

Anti-fire Dust Elastic Armor Shield Steel Bellow Cover Overview

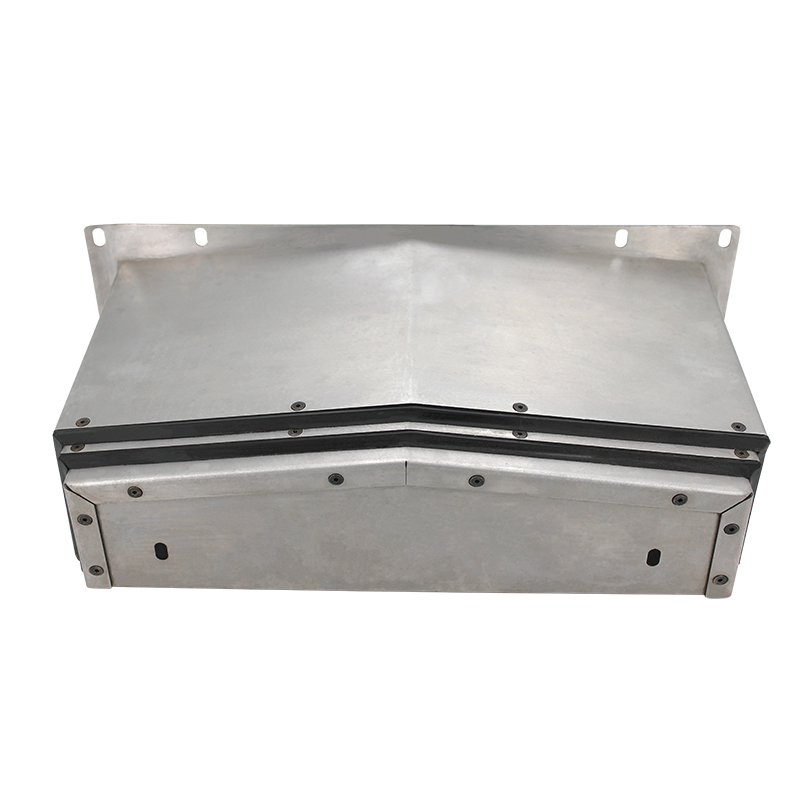

The Anti-fire Dust Elastic Armor Shield Steel Bellow Cover is a protective, multi-layer guard engineered to shield machine elements—such as linear guideways, ball screws, cylinders, and cable routes—from hot chips, sparks, abrasive dust, and coolant splash. Combining a flexible bellows profile with a steel armor shield, it delivers dual protection: elastic sealing against contaminants and robust impact and heat resistance for harsh manufacturing environments. Typical constructions include heat-resistant technical fabrics, inner elastomer coatings for sealing, and external steel lamellas/plates that deflect hot swarf and extend thermal endurance. End flanges and clamp rings allow quick mounting to machine frames, while the bellows geometry supports smooth, high-speed travel and compact retraction.

For B2B decision makers in the General equipment manufacturing industry and the Manufacturing of mechanical components, the cover enhances process reliability and dimensional stability by keeping precision surfaces clean and safe. Configurations can be tailored for stroke length, speed classes, aperture size, and interface details. Shijiazhuang Anjie Electric Co., Ltd.—the manufacturer behind this solution—offers engineered customization and rigorous quality control to match OEM and retrofit needs, helping plants standardize guarding across CNC machines, laser/plasma systems, and automated transfer lines.

Benefits & Use Cases of Anti-fire Dust Elastic Armor Shield Steel Bellow Cover in Manufacturing of mechanical components

In machining centers, grinding cells, welding lines, and cutting systems, the Anti-fire Dust Elastic Armor Shield Steel Bellow Cover protects critical motion axes where heat and particulate are constant threats. Applications include CNC X/Y/Z axes, robot 7th-axis modules, linear transfer systems, screw drives on lathes and grinders, and actuator rods in assembly equipment. Compared with fabric-only bellows, the integrated steel armor layer provides reliable shielding from hot chips and radiant heat. Compared with telescopic steel covers, the elastic bellows design offers lower mass, quieter operation, and faster acceleration, which is ideal for high-dynamic servo axes.

- Fire and heat resilience: steel armor helps deflect sparks and hot chips in welding, foundry, and cutting operations.

- Superior sealing: elastic convolutions and edge seals reduce dust ingress, preserving accuracy of guideways and screws.

- Compact footprint: excellent compression ratio keeps machines ergonomic and easy to service.

- Customization: tailored sizes, end connections, and travel speeds for OEM standardization and retrofits.

Backed by Shijiazhuang Anjie Electric Co., Ltd.’s application engineering, customers can specify materials, lamella geometry, and mounting details to suit coolant exposure, chip load, or line speed—helping new equipment launches and upgrades hit performance targets faster.

Cost, Maintenance & User Experience

Total cost of ownership improves when precision components are shielded from heat and contamination. The Anti-fire Dust Elastic Armor Shield Steel Bellow Cover helps extend service intervals for ball screws and linear guides, reducing unplanned downtime and scrap risk tied to positional errors. Compared to heavy telescopic covers, the lower moving mass can also alleviate drive loads, contributing to energy efficiency on high-duty axes. Many B2B buyers assess ROI by comparing the cover’s cost with averted failures, spare-part spend, and avoided production stops—often realizing payback within typical maintenance cycles, depending on process severity and utilization.

- Durability: multi-layer construction resists abrasion and thermal shock; steel armor mitigates chip impact and surface burns.

- Easy upkeep: periodic wipe-downs, visual checks for lamella integrity, and clamp/fastener inspection keep uptime high.

- Serviceability: modular sections and standardized end flanges enable fast swap-outs during scheduled maintenance.

Users in the General equipment manufacturing industry report cleaner machine interiors, fewer axis alarms related to contamination, and smoother motion profiles after adopting armored bellows. Shijiazhuang Anjie Electric Co., Ltd. supports lifecycle value with responsive engineering, clear installation guidance, and consistent lead times for replacements and spares.

Sustainability & Market Trends in manufacturing

Global manufacturing is tightening expectations around safety, emissions, and resource efficiency. Guarding that controls hot chips, dust, and mist helps plants align with safety practices and housekeeping standards, while reducing the risk of ignition events around flammable residues. Longer-lasting covers mean fewer replacements and less material waste over the asset lifetime. Keeping guideways clean sustains motion efficiency, which can indirectly lower energy usage through reduced friction and smoother axis movement.

Market trends favor compact, high-speed automation with robust multi-hazard protection. The Anti-fire Dust Elastic Armor Shield Steel Bellow Cover aligns well with this shift: it delivers thermal, particulate, and impact protection in a lightweight format. Shijiazhuang Anjie Electric Co., Ltd. adopts forward-looking material choices and production practices designed to meet evolving compliance expectations, while offering customization to help OEMs and end users achieve both performance and sustainability goals.

Conclusion on Anti-fire Dust Elastic Armor Shield Steel Bellow Cover from Shijiazhuang Anjie Electric Co., Ltd.

For B2B leaders in the General equipment manufacturing industry and the Manufacturing of mechanical components, the Anti-fire Dust Elastic Armor Shield Steel Bellow Cover offers a reliable path to higher uptime, better accuracy, and safer operations. Its armored, elastic design provides the right mix of heat resistance, sealing performance, and dynamic motion capability. Backed by Shijiazhuang Anjie Electric Co., Ltd.’s engineering and customization expertise, it’s a proven upgrade for both OEM builds and retrofits. Contact us: email: marketing@agiletech.cn. Visit our website: https://www.agilechains.com