Engineering Impenetrable Seals for Industrial Dust Cover Bellows

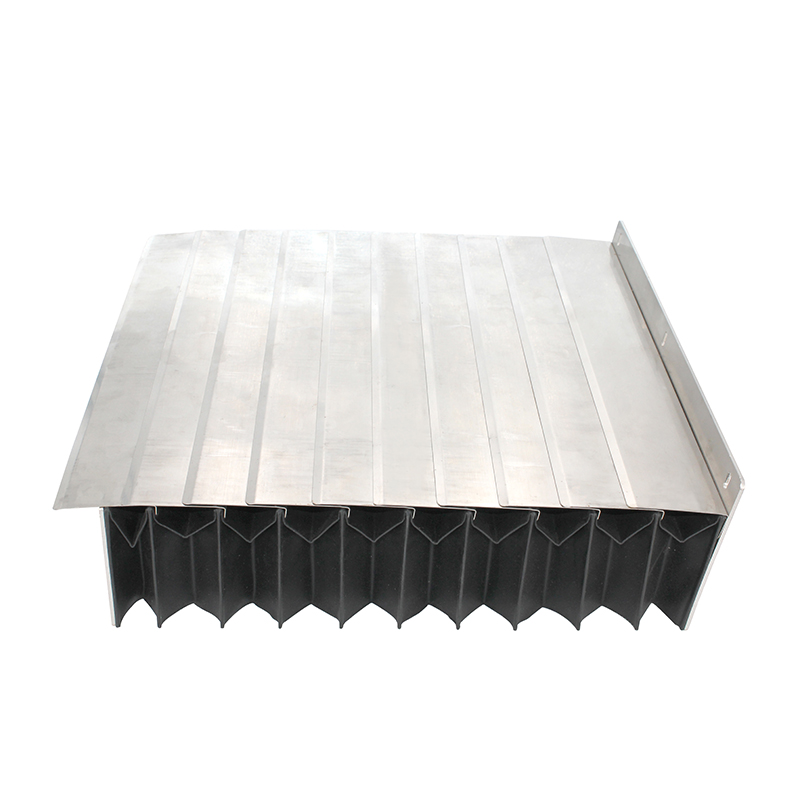

In pharmaceutical cleanrooms, semiconductor fabs, and precision CNC shops, micron-scale dust is the silent saboteur. Standard dust bellow covers fail when particles under microns infiltrate bearings, optics, or sensitive electronics. Preventing this requires a technological arms race – advanced sealing systems engineered into dust cover bellows and fire resistant bellow covers that create dynamic, uncompromising barriers. For wholesale buyers protecting high-value equipment fleets, mastering these sealing technologies translates directly to extended component life, reduced contamination downtime, and significant maintenance cost savings.

Shijiazhuang Agile company is established since 2008. We got more than 13 years experience in the production of drag chain, guide rail bellow cover, nylon corrugated bellow pipe and related products. Our products focus on cable protection, rail protection in the reciprocating motion. We got about 100 employees and our factory is located in Yanshan county of Hebei province, and got about 6500 square meters’ production area. Our office is located at Shijiazhuang city, with about 300 square meters’ area. It is about 400 kilo meters from Beijing for location. Quality first is our idea. We put prior importance in quality control. At the same time we are trying much harder to control our price within reasonable scope.

Lip Seals & Compression Gaskets: The First Line of Defense in Dust Bellow Covers -h2

Precision-engineered contact seals form the foundation of micron exclusion:

- Multi-Lip Radial Seals:Elastic silicone or fluorosilicone lips press dynamically against shafts or housings. Multiple lips create successive barrier stages – trapping particles in labyrinthine channels before they breach the dust cover bellows(https://www.agilechains.com/machine-shield-fire-resistant-organ-meatal-dust-bellow-cover.html) interior. Lip geometry is optimized for low friction and constant contact pressure.

- Conformable Flange Gaskets:Closed-cell foam rubber or thermoplastic elastomer gaskets compress between mounting flanges and machine surfaces. They fill microscopic imperfections, achieving IP6K-rated sealing (complete dust exclusion) at the dust bellow cover's fixed points. Material selection prevents compression set over time.

- Self-Energizing Pressure Seals:In pressurized environments, internal pressure actively forces seal lips outward against contact surfaces, enhancing the dust cover bellows barrier effect as operating intensity increases.

Labyrinth Seals & Non-Contact Barriers: Zero Dust Bellow Cover Friction Exclusion -h2

When contact seals aren’t feasible, engineered air gaps block particulates:

- Multi-Stage Labyrinth Channels:Complex pathways machined into end caps or internal rings. Airflow changes direction rapidly, forcing micron particlesto impact walls and fall out before entering the fire resistant bellow cover. Especially critical in high-speed axes where friction from lip seals is unacceptable.

- Vortex Generators & Air Curtains:Integrated compressed air nozzles create controlled airflows across openings. This "air knife" deflects incoming dust away from the dust bellow coverentry point – ideal for extremely hazardous environments like silica dust handling.

- Magnetic Seal Enhancement:Integrating ferrous strips into fabric edges paired with magnetic mounting profiles creates a strong, uniform pull. This forces the dust cover bellows material into near-perfect conformity with irregular surfaces, eliminating gaps where fines could penetrate.

Fire Resistant Bellow Cover Integrity: Sealing Under Extreme Conditions -h2

Fire resistant bellow covers demand seals that survive thermal catastrophe:

- Intumescent Sealants:Expanding graphite- or silicate-based compounds injected into flange grooves. During fire exposure, they expand, sealing gaps caused by metal distortion and actively blocking flames/smoke from breaching the fire resistant bellow cover.

- Ceramic Fiber Rope Seals:Braided alumina-silica fibers withstand. Packed into joints, they maintain compression and flexibility during thermal cycling, ensuring the dust bellow coverremains sealed against hot ashes and sparks in foundry applications.

Validation & Certification: Proving Dust Bellow Cover Micron-Level Performance -h2

Sealing claims require brutal, standardized verification:

- Thermal Cycling Leak Tests:Cycling the fire resistant bellow coverbetween extreme temperatures while monitoring internal particulate counts via laser particle counters verifies seal integrity under real-world thermal stress.

- DIN Dust Chamber Testing:Quantifying ingress protection levels using calibrated Arizona test dust – essential for wholesale buyers needing guaranteed dust bellow coverperformance in regulated industries like medical device manufacturing.

- Post-Fire Seal Functionality Assessment:Verifying seals within fire resistant bellow coversremain functional after flame exposure – critical for containment during emergency shutdowns.

Frequently Asked Questions About Dust Bellow Cover Seal Technologies -h2

How do lip seals handle dust cover bellows shaft misalignment without leaking?-h3

Advanced multi-lip designs and highly elastic materials allow significant radial/angular shaft deflection while maintaining constant contact pressure. The dust cover bellows seal dynamically conforms to minor misalignments common in industrial settings.

Can labyrinth seals truly achieve dust bellow covers tightness?-h3

Yes, with precise channel geometry and controlled internal airflow. High-quality dust bellow covers use optimized labyrinths that achieve without contact, ideal for ultra-high-speed or sensitive applications.

Do fire-resistant seals compromise dust bellow cover protection?-h3

Not in engineered solutions. Intumescent materials activate only under extreme heat. Below this threshold, they function like standard gaskets. Ceramic fiber ropes provide continuous particle blocking across all temperatures in fire resistant bellow covers.

How often should dust bellow cover seals be inspected in high-dust environments?-h3

Schedule visual checks quarterly and functional testing annually. Monitor for: hardened/cracked lip seals, compressed gaskets losing resilience, or visible gaps in magnetic/labyrinth seals. High-abrasion environments demand more frequent dust bellow cover inspections.

Are custom sealing solutions viable for dust cover bellows wholesale procurement ?-h3

Absolutely. Reputable manufacturers maintain libraries of seal profiles, materials, and integration methods. Providing your dust particle size distribution, temperature range, and shaft tolerances allows them to configure optimal, scalable sealing for bulk dust cover bellows orders.

Victory in the micron war demands sealing technologies engineered with molecular precision and validated under brutal conditions. From self-energizing lip seals to zero-friction labyrinths and fire-activated intumescents, these systems transform ordinary dust cover bellows, and fire resistant bellow covers into impenetrable fortresses. For wholesale buyers, prioritizing advanced sealing isn’t an option – it’s the core strategy for protecting capital equipment, ensuring product purity, reducing maintenance frequency, and safeguarding productivity across industrial fleets. The true cost of contamination dwarfs the investment in bellows engineered to exclude it at the micron level.